- SLM 3D Printed Brass Cheetah Statue Film Award Prize

- MJF 3D Printed Full-color Elder Man Head Miniature

Gallery

About Project

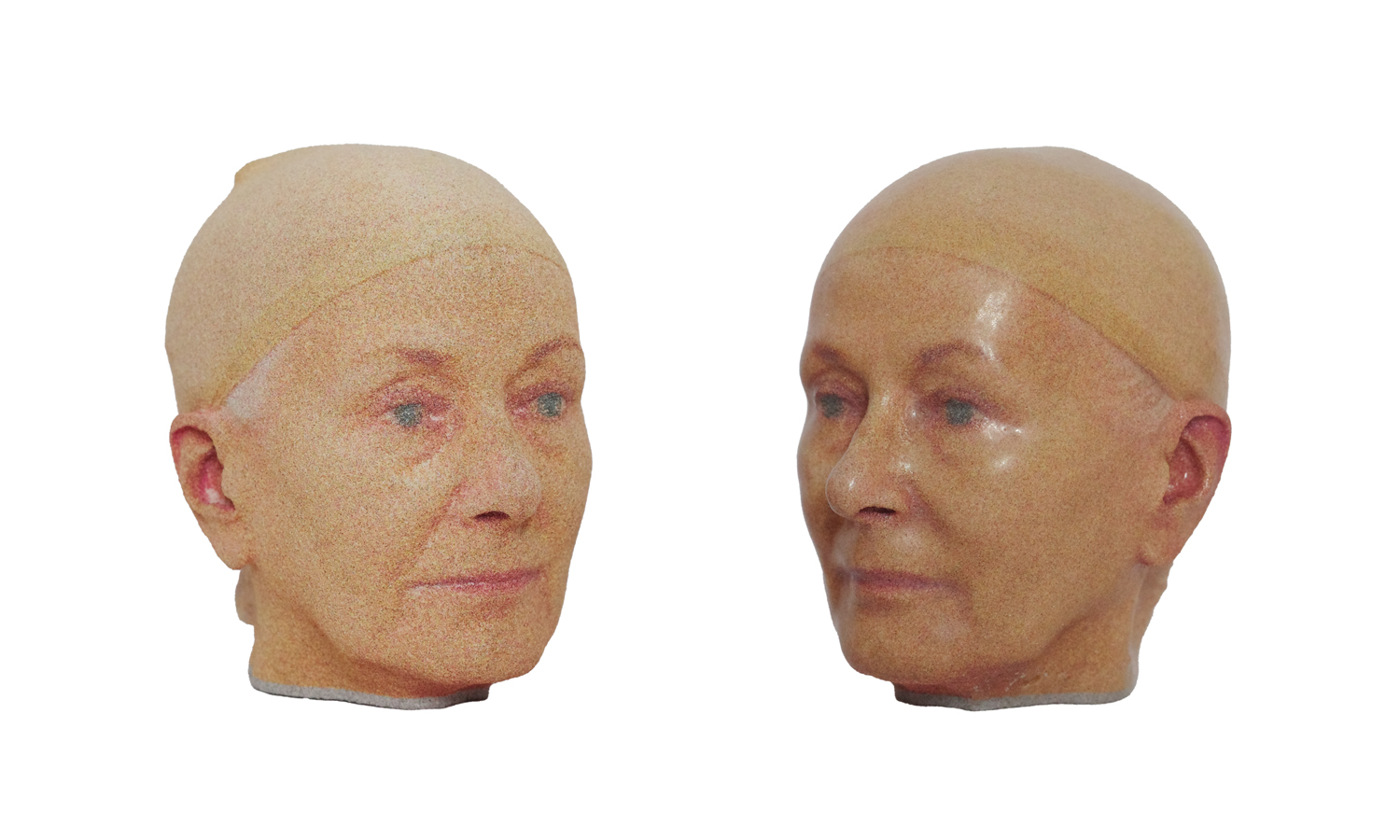

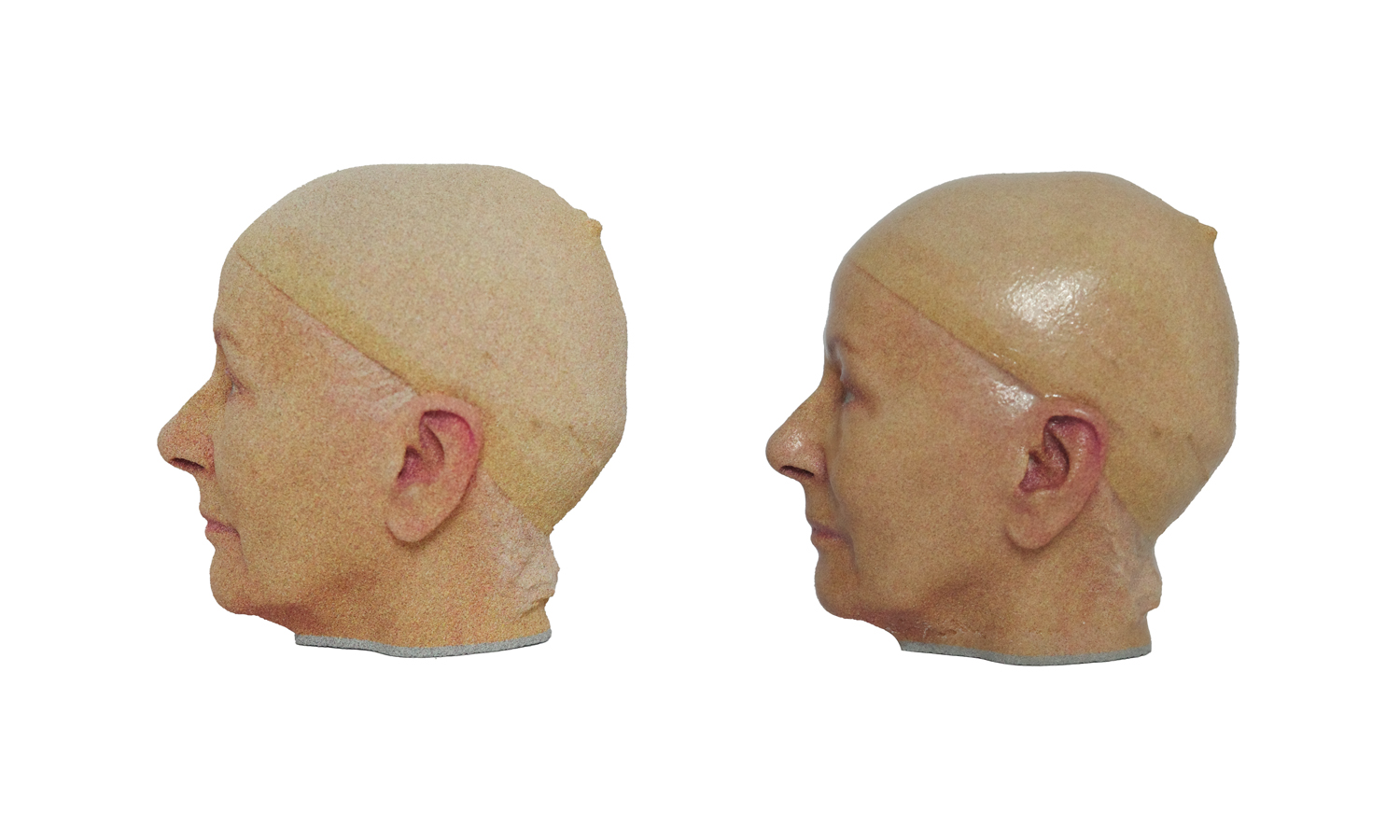

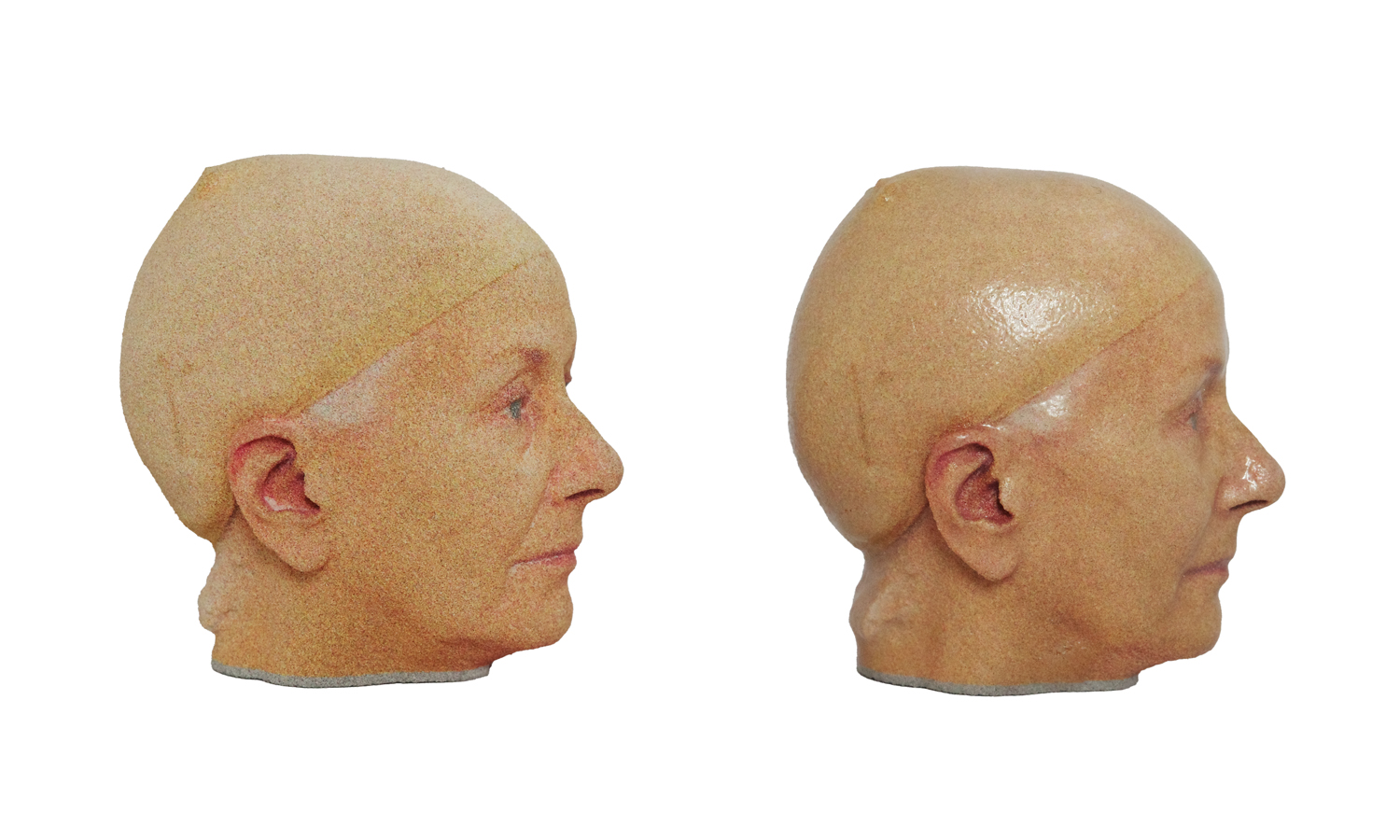

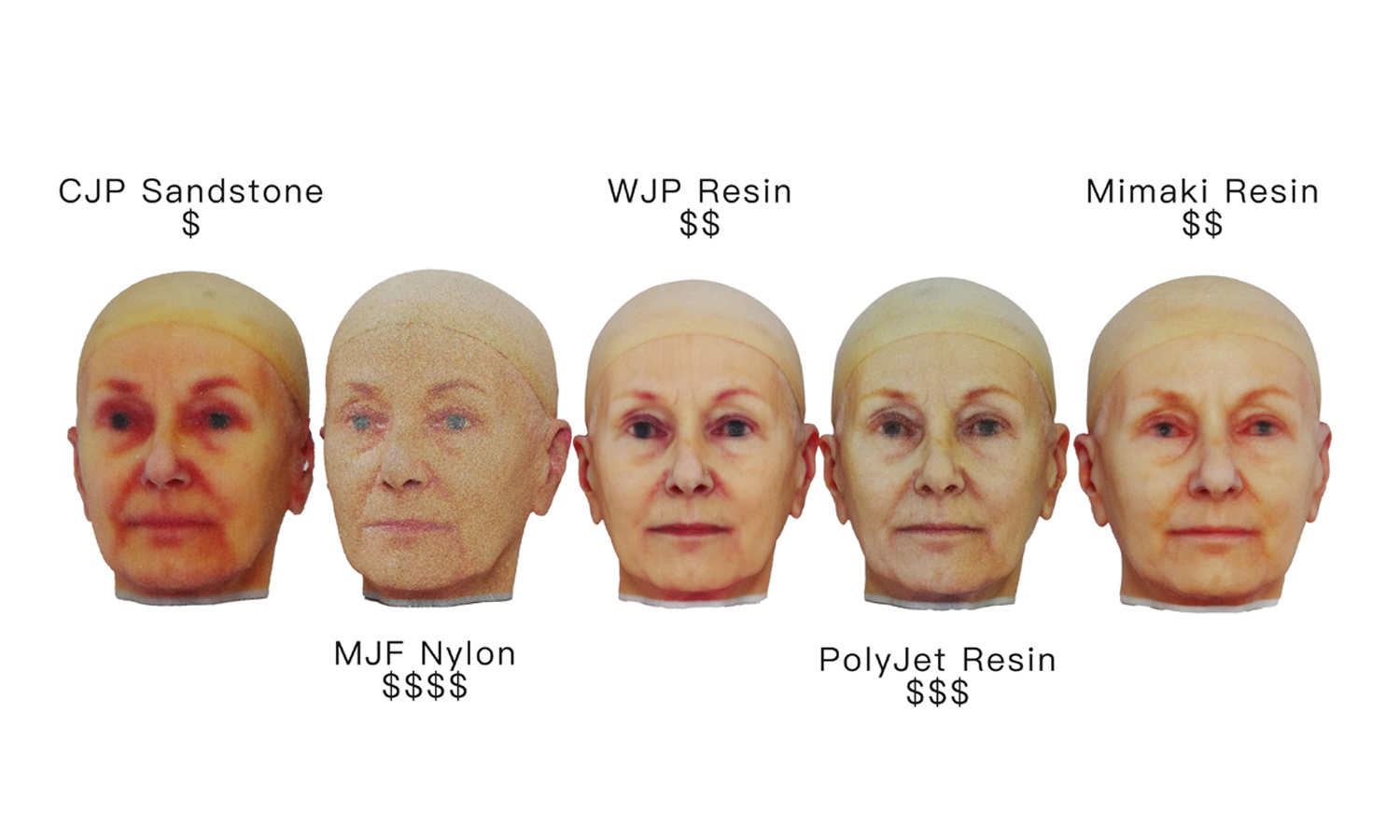

Take a closer look at these fascinating 3D-printed elder woman head miniatures, produced with Multi Jet Fusion (MJF) technology. On the left, you see the model in its raw, unfiinished state directly from the printer. Notice the slightly desaturated colors, the presence of subtle gray-white speckles, and how some of the finer pattern details are a bit soft. This finish offers a unique, almost pastel-like texture, reminiscent of powdered pigments.

On the right, the same miniature has been enhanced with a thin layer of clear acrylic oil. This simple post-processing step significantly deepens the colors, reduces the visibility of the speckles, and brings out more of the intricate details, resulting in a smoother, more vibrant appearance.

While the raw MJF finish might appeal to those who prefer a matte, textured look, the clear acrylic oil demonstrates how a simple coating can elevate the visual fidelity and color saturation of MJF prints.

Why Choose MJF for Your Full-Color Prints?

Despite the slight desaturation and speckling in the raw finish, MJF technology excels in producing complex geometries with good structural integrity. If your project demands intricate models with a certain level of strength, and you appreciate the unique, powdered-pigment-like texture, MJF is an excellent choice. Furthermore, as shown, post-processing options can further refine the aesthetic.

Unlock the Potential of Full-Color 3D Printing with FacFox!

Ready to bring your intricate designs to life with vibrant, full-color 3D prints? FacFox offers professional MJF full-color 3D printing services, delivering high-quality results for a wide range of applications. Whether you need detailed prototypes, lifelike miniatures, or unique artistic creations, our MJF service can meet your needs. Explore the possibilities and get a quote today at FacFox.com!

Solution

- Step 1: Digital 3D model data was prepared.

- Step 2: A thin layer of powdered material was spread across the build platform.

- Step 3: Detailing and fusing agents were selectively jetted onto the powder bed according to the model’s cross-section.

- Step 4: An infrared energy source passed over the build area, fusing the material where the agents were applied.

- Step 5: The build platform was lowered.

- Step 6: Steps 2-5 were repeated layer by layer until the entire miniature was formed within the powder cake.

- Step 7: The finished miniature was removed from the build chamber and excess powder was broken away.

- Step 8: For the right miniature, a thin layer of clear acrylic oil was applied.