Gallery

About Project

Pipe fittings are essential components of plumbing systems that connect and control the flow of fluid. They are usually made of metal or plastic with various shapes and sizes to suit different applications. Pipe fittings require high precision and durability to withstand pressure and corrosion.

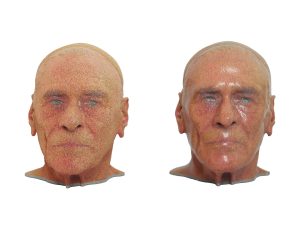

One of our clients, a leading supplier of plumbing products, approached us with a challenge: they needed a custom CNC-milled double Y adaptor using aluminum 6061 for their new project. They offered the 3D model.

We accepted the challenge and delivered the solution. Using our advanced CNC milling machines and skilled operators, we were able to produce the fitting with high accuracy and efficiency. We followed the clientвҖҷs design and specifications closely, and ensured that the tightest tolerances were met.

The client was very satisfied with the result. They tested the fitting and found that it performed flawlessly in their plumbing system. They praised our quality, speed, and professionalism, and expressed their interest in working with us again for future projects.

At FacFox, we are proud to offer CNC milling services for various materials and applications, including aluminum 6061 pipe fittings. We have the expertise, equipment, and experience to meet your needs and exceed your expectations. Contact us today to get a free quote for your CNC milling project.

Solution

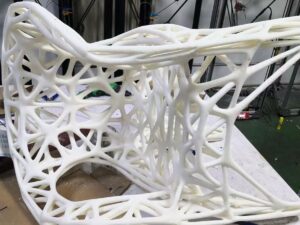

- Step 1: The clientвҖҷs design and specifications of the pipe fitting were received and verified for accuracy. The CAD files were converted into a CNC-compatible format with the software.

- Step 2: A suitable type of CNC milling machine was selected based on the shape and size of the manifold. The appropriate cutting tools and parameters were chosen to optimize the machining efficiency and quality.

- Step 3: The aluminum 6061 block was prepared and secured on the machine table. The G-codes were entered into the machine controller to instruct the movements of the cutting tools. The aluminum block was milled into the desired shape and size of the pipe fitting.

- Step 4: The workpiece was inspected during and after the milling process for dimensional accuracy and surface finish. The dimensions and tolerances were measured with a caliper and a micrometer. The surface finish was checked with a roughness tester. It met all the requirements of the client.