Material Rubber

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

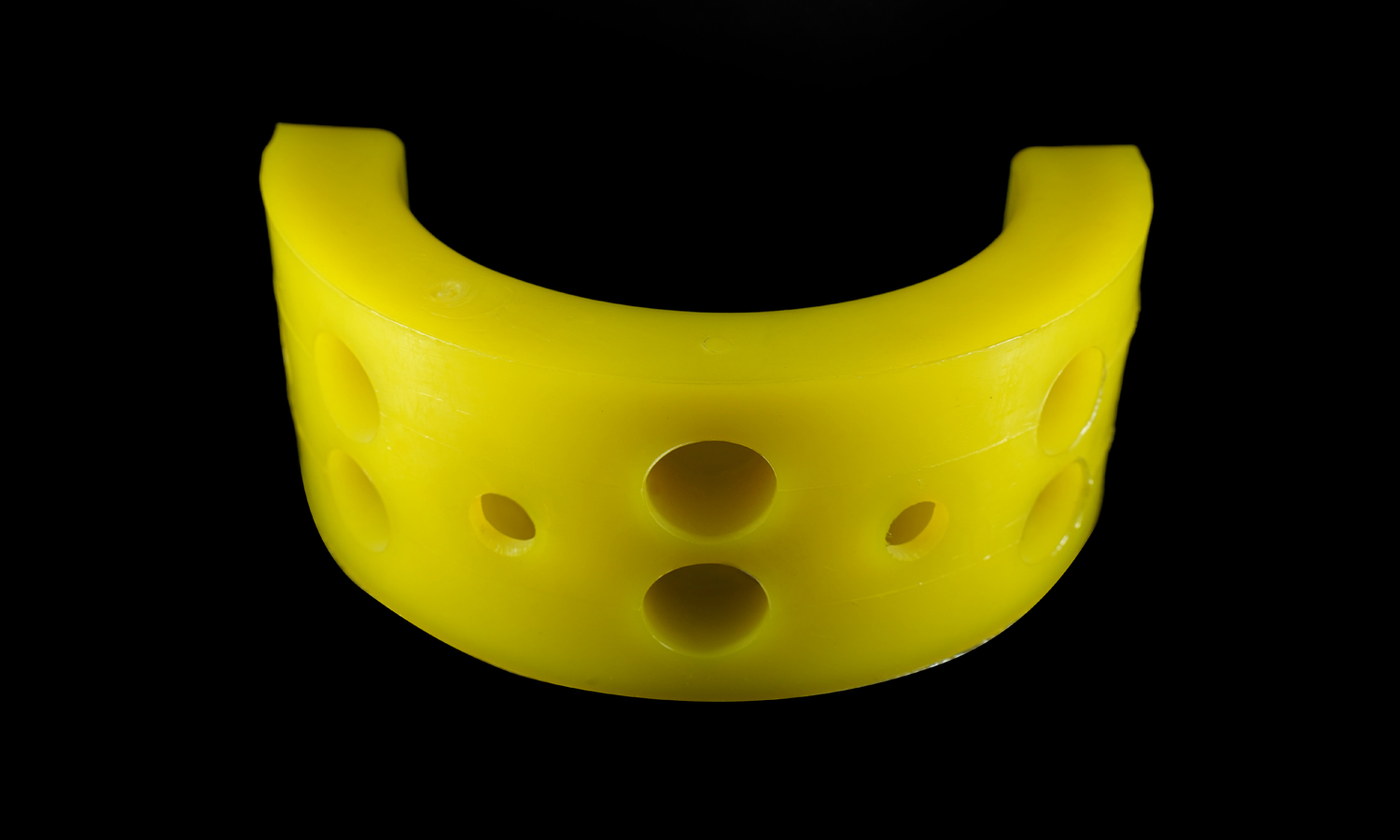

Ever wondered about the small but mighty components that keep our industrial world flowing smoothly? Take, for instance, the robust yellow object pictured here. While it might look simple, this is a prime example of a polyurethane (PU) pipe support вҖ“ a true unsung hero in countless applications.

Pipe supports are critical for maintaining the integrity and functionality of piping systems. They prevent sagging, dampen vibrations, and protect pipes from wear and tear, especially in harsh environments. The choice of material is paramount, and that’s where polyurethane shines.

Why Polyurethane for Pipe Supports?

- Exceptional Durability: PU boasts incredible abrasion resistance, making it ideal for high-wear situations. It can withstand constant friction and impact without degrading.

- Corrosion Resistance: Unlike metal supports, PU is impervious to rust and many chemicals, making it perfect for marine, chemical, and outdoor installations.

- Vibration Dampening: Its inherent elasticity helps absorb shocks and vibrations, reducing stress on the pipes and minimizing noise.

- High Load-Bearing Capacity: Despite its flexibility, polyurethane can be engineered to support significant weight without deforming permanently.

- Customizable: PU can be molded into virtually any shape and hardness, allowing for tailored solutions to specific pipe diameters and environmental challenges.

These C-shaped sections, often bolted together, cradle pipelines, protecting them from structural damage and ensuring they remain in optimal position. From oil and gas pipelines to water treatment facilities, the reliability of these components is crucial for preventing costly failures and ensuring operational efficiency.

Need custom polyurethane components that perform under pressure?

At FacFox, we specialize in advanced polyurethane manufacturing services. Whether you require bespoke pipe supports, custom seals, or other durable PU parts, our expertise in precision molding and material science ensures high-quality, long-lasting solutions tailored to your exact specifications. Trust FacFox to bring your toughest ideas to life with superior polyurethane manufacturing.

Solution

- Step 1: A high-precision master pattern of the pipe support was created, typically via CNC machining or 3D printing, to define the exact geometry.

- Step 2: A two-part mold was fabricated around the master pattern using a durable material, such as silicone rubber or epoxy resin, to capture the intricate details of the bolt recesses and interlocking ends.

- Step 3: The internal surfaces of the mold were treated with a release agent to ensure the cured polyurethane could be extracted without sticking.

- Step 4: The liquid polyurethane precursorsвҖ”a polyol resin and an isocyanate hardenerвҖ”were measured and mixed in a specific ratio, along with yellow pigment.

- Step 5: The mixture was placed in a vacuum chamber where entrapped air was degassed to prevent bubbles or structural voids in the final support.

- Step 6: The degassed liquid was poured into the open mold cavity under atmospheric pressure, allowing gravity to fill the complex shapes around the bolt-hole inserts.

- Step 7: The mold was placed into a temperature-controlled oven, where the chemical cross-linking reaction was accelerated and the part was allowed to solidify.

- Step 8: The solidified pipe support was demolded by separating the mold halves and removing the internal pins that formed the bolt holes.

- Step 9: A post-curing phase was completed in an oven for several hours to ensure the material reached its maximum physical strength and abrasion resistance.

- Step 10: Any excess material at the parting line (known as “flash”) was trimmed manually to achieve the final finished profile.