Gallery

About Project

Imagine a mouse shell that feels like an extension of your hand, a whisper of weight translating into lightning-fast flicks and pinpoint accuracy. That’s precisely what Piranha, a visionary designer in the realm of custom peripherals, has achieved with his creation: a lightweight mouse shell crafted from SLS 3D printed PA 11 CF (carbon fiber filled nylon 11).

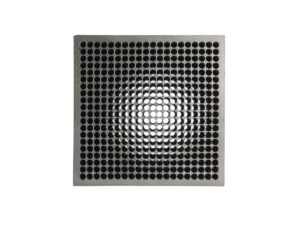

This isn’t just another mouse shell; it’s a meticulously engineered piece of art. The structure is a testament to Piranha’s understanding of ergonomics and performance. The shell features a carefully optimized honeycomb hollowed structure, drastically reducing weight without sacrificing rigidity. This intricate lattice, visible through strategic cutouts, not only shaves precious grams but also adds a unique, futuristic aesthetic. The external surface is smooth and tactile, providing a comfortable grip even during intense gaming sessions.

The material choice, PA 11 CF, is a game-changer. This carbon fiber-reinforced nylon offers an exceptional strength-to-weight ratio. It’s significantly lighter than traditional mouse shell materials, yet incredibly durable. The carbon fiber infusion also imparts a subtle, textured finish that feels premium and provides enhanced grip. The printing quality is remarkable. The SLS process, known for its precision and fine detail, has flawlessly captured Piranha’s intricate design. Layers are virtually invisible, resulting in a smooth, consistent surface. The sharp edges and delicate internal structures are perfectly rendered, showcasing the capabilities of advanced 3D printing.

The result is a mouse shell that feels incredibly light and responsive. The reduced inertia translates to faster movements and improved control, giving gamers a competitive edge. The combination of Piranha’s innovative design and the exceptional properties of PA 11 CF has created a truly remarkable product.

If you’re looking to bring your own innovative designs to life with the robust and lightweight properties of PA 11 CF, look no further than FacFox. With their expertise in SLS 3D printing and a wide range of high-performance materials, including PA 11 CF, FacFox can turn your ideas into reality. Their commitment to quality and precision ensures that your projects will be executed to the highest standards. Explore the possibilities of PA 11 CF 3D printing with FacFox and experience the future of manufacturing.

Solution

- Step 1: CAD Model Design The mouse shell was designed in a CAD software, creating a detailed 3D model.

- Step 2: File Preparation. The CAD file was converted to an STL format and prepared for 3D printing. This involved optimizing the design for the SLS process and ensuring proper orientation for printing.

- Step 3: Powder Preparation. Fine PA 11 CF powder was carefully sieved and loaded into the SLS machine’s powder bed.

- Step 4: Printing Process. The SLS machine’s laser selectively sintered the PA 11 CF powder layer by layer, following the 3D model. Each layer was fused to the previous one, gradually building the mouse shell.

- Step 5: Cooling. After printing, the entire powder bed was allowed to cool down slowly to prevent warping or cracking of the printed object.

- Step 6: Part Retrieval. The solidified mouse shell was carefully extracted from the powder bed, and excess powder was removed.

- Step 7: Post-Processing. The mouse shell was cleaned to remove any residual powder. This might have involved media tumbling or air blasting.

- Step 8: Quality Inspection. The finished mouse shell was inspected for dimensional accuracy and surface finish to ensure it met the design specifications.