- Transparent Resin 3D Printed Parts with Polished, Frosted, and Dyed Finishes

- Transparent SLA 3D Printed Flow Channel Models for Visualization

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 3 workdays

Gallery

About Project

Transparent resin printing is one of the most visually striking and technically precise applications of stereolithography (SLA). At FacFox, we’ve helped clients from a variety of industries – including healthcare, architecture, art, and product design – transform their complex digital models into clear, tangible prototypes. These recent projects illustrate just how versatile our SLA transparent resin printing can be.

The first example features anatomical bone models printed in clear resin. With their smooth, frosted finish and fine anatomical details, these parts are ideal for medical training, surgical planning, and museum exhibits. The semi-transparent surface allows educators and professionals to study both the external and internal structures simultaneously.

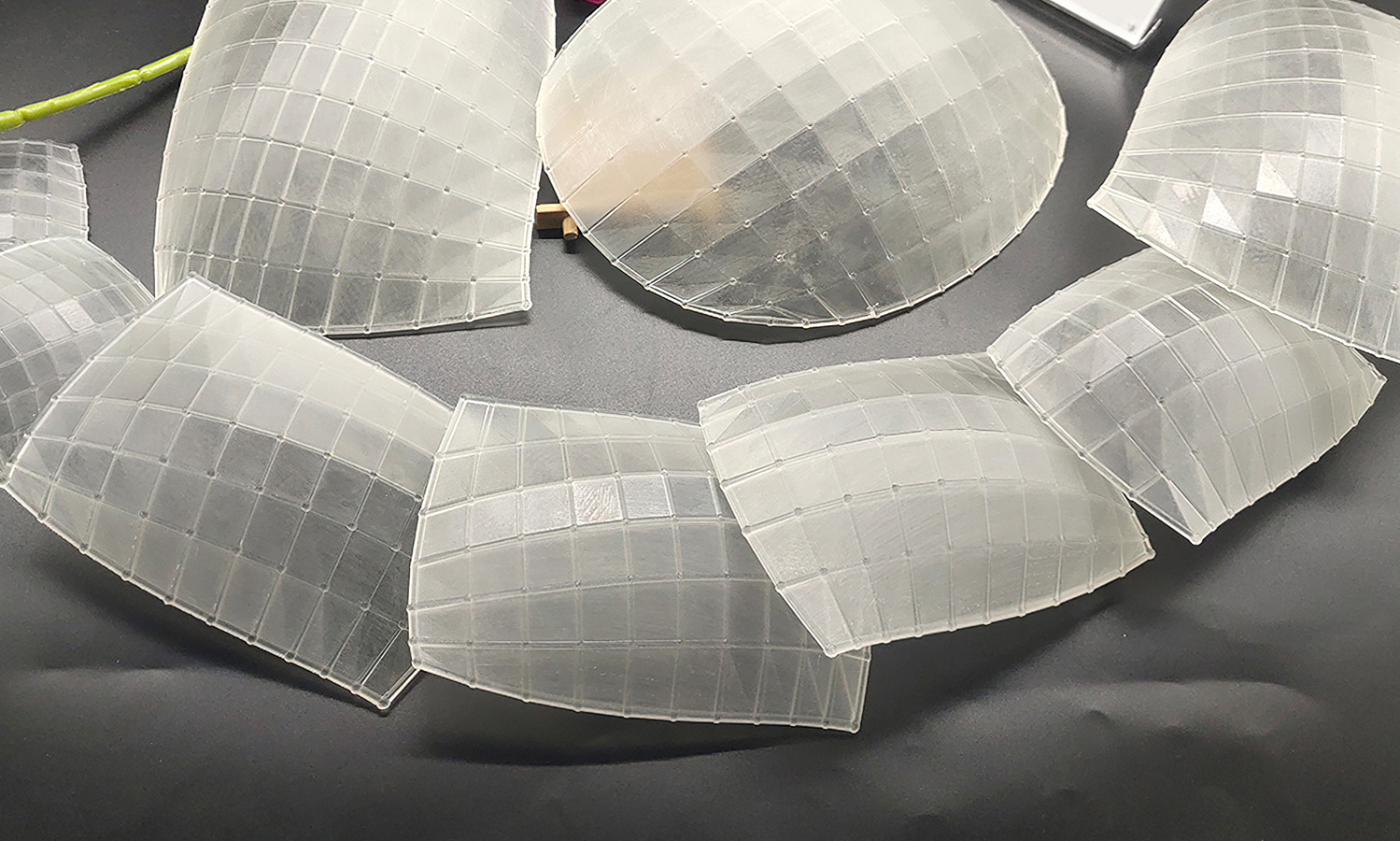

In another case, we produced curved lattice panels used for architectural and structural research. The precise grid geometry and consistent thickness demonstrate SLA’s ability to reproduce subtle curvature and intersecting details – perfect for design validation and optical form studies.

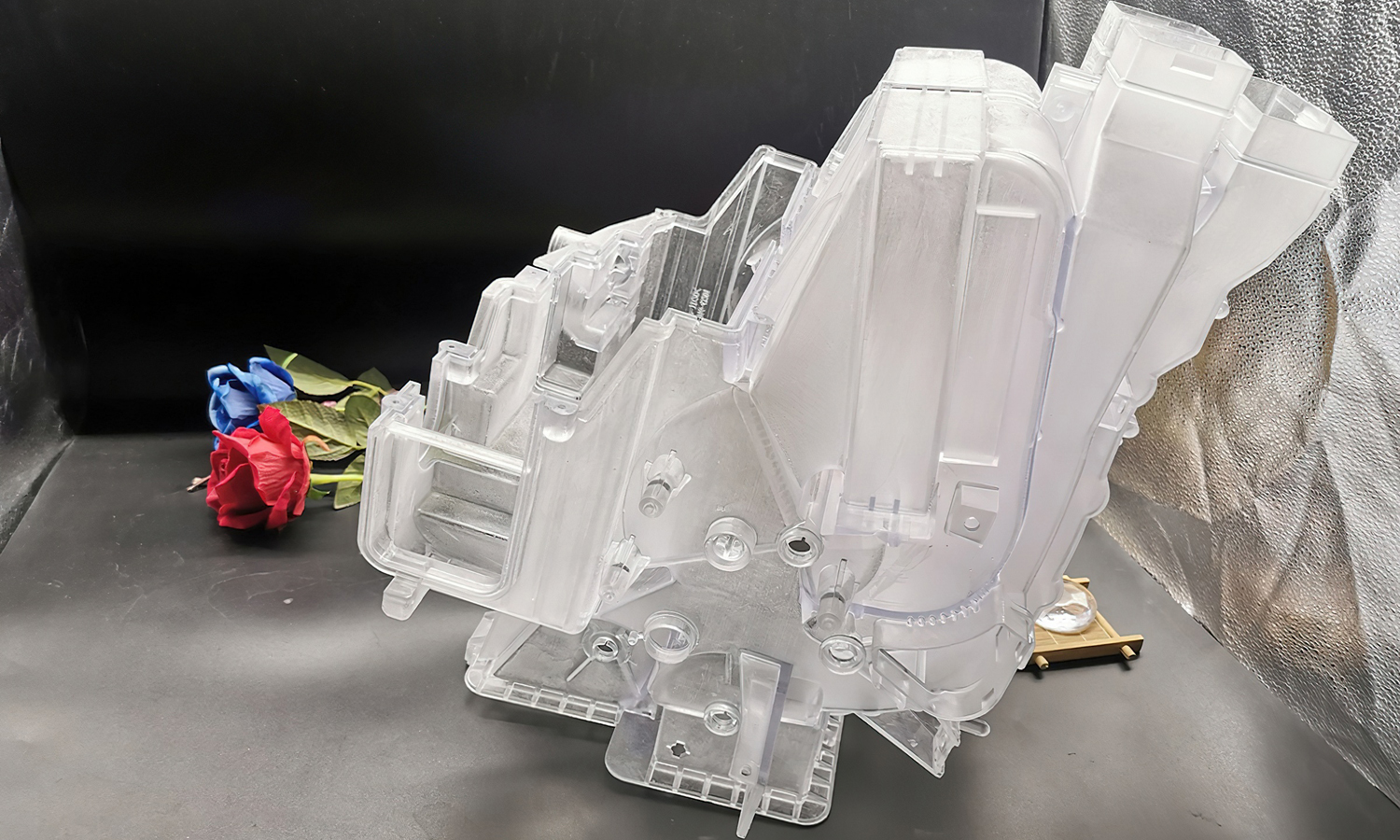

For industrial and mechanical clients, we printed large transparent housings and functional prototypes with internal channels and mounting points. These clear models make it easy to visualize airflow, assembly fit, and fluid dynamics inside complex enclosures – a huge advantage for engineers and designers refining their products before production.

Not all clear resin prints are purely functional – some are artistic. One highlight is the horse sculpture with modular limbs, printed entirely in translucent resin. The soft light diffusion and satin sheen give it a distinctive aesthetic appeal, proving that SLA technology can serve both precision engineering and creative craftsmanship.

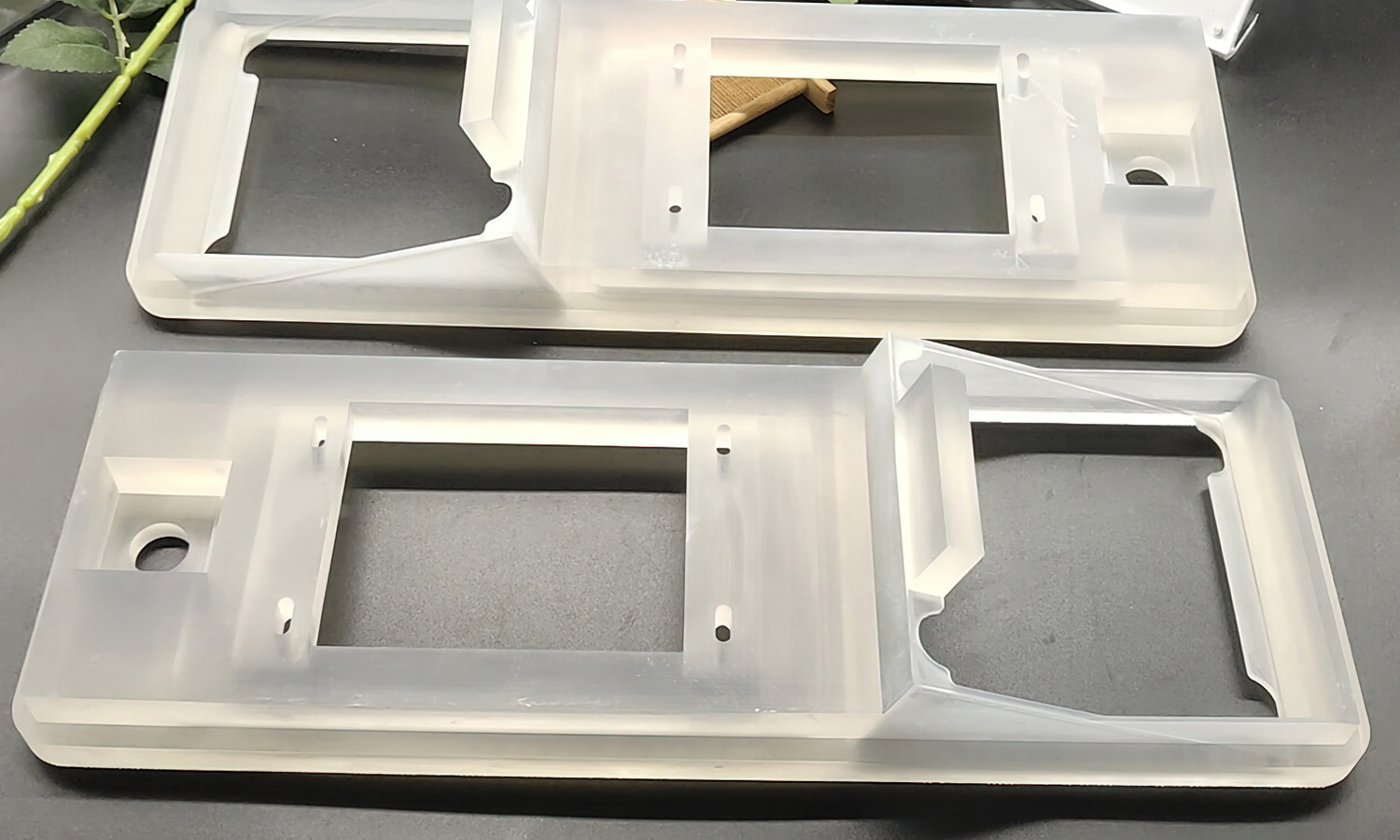

Finally, a series of ergonomic surface and lens-like prototypes show the potential for optical and consumer product development. The subtle textures, frosted edges, and accurate curvature make them suitable for wearable device shells, lighting components, and design mock-ups.

Bring Your Ideas to Light with FacFox

Whether you need a transparent prototype to visualize internal mechanisms, an art piece with glass-like beauty, or a scientific model for research and education, FacFox’s SLA 3D printing service can make it real. Our clear resin materials deliver exceptional accuracy, smooth finishes, and customizable transparency to match your project’s needs.

Explore more at FacFox.com – where your ideas take shape in every layer.

Solution

- Step 1: 3D files were checked and repaired to ensure watertightness and proper tolerances.

- Step 2: Clear SLA resin and a frosted finish were selected for optimal translucency.

- Step 3: Models were oriented and supported to minimize deformation and marks.

- Step 4: Parts were printed on industrial SLA machines with fine layer precision.

- Step 5: Prints were cleaned in solvent baths and fully UV-cured.

- Step 6: Supports were carefully removed and surfaces were sanded smooth.

- Step 7: Frosted or semi-clear finishes were adjusted by polishing and blasting.

- Step 8: Multi-part assemblies were fitted and bonded where necessary.

- Step 9: Final inspection ensured dimensional accuracy and surface quality.

- Step 10: Parts were cleaned, labeled, and securely packaged for delivery.