- MJF TPU 3D Printed Flexible Phone Case Shore 90A Dyed Black

- CNC Milled POM Spur Gear Custom Plastic Flywheel

Gallery

About Project

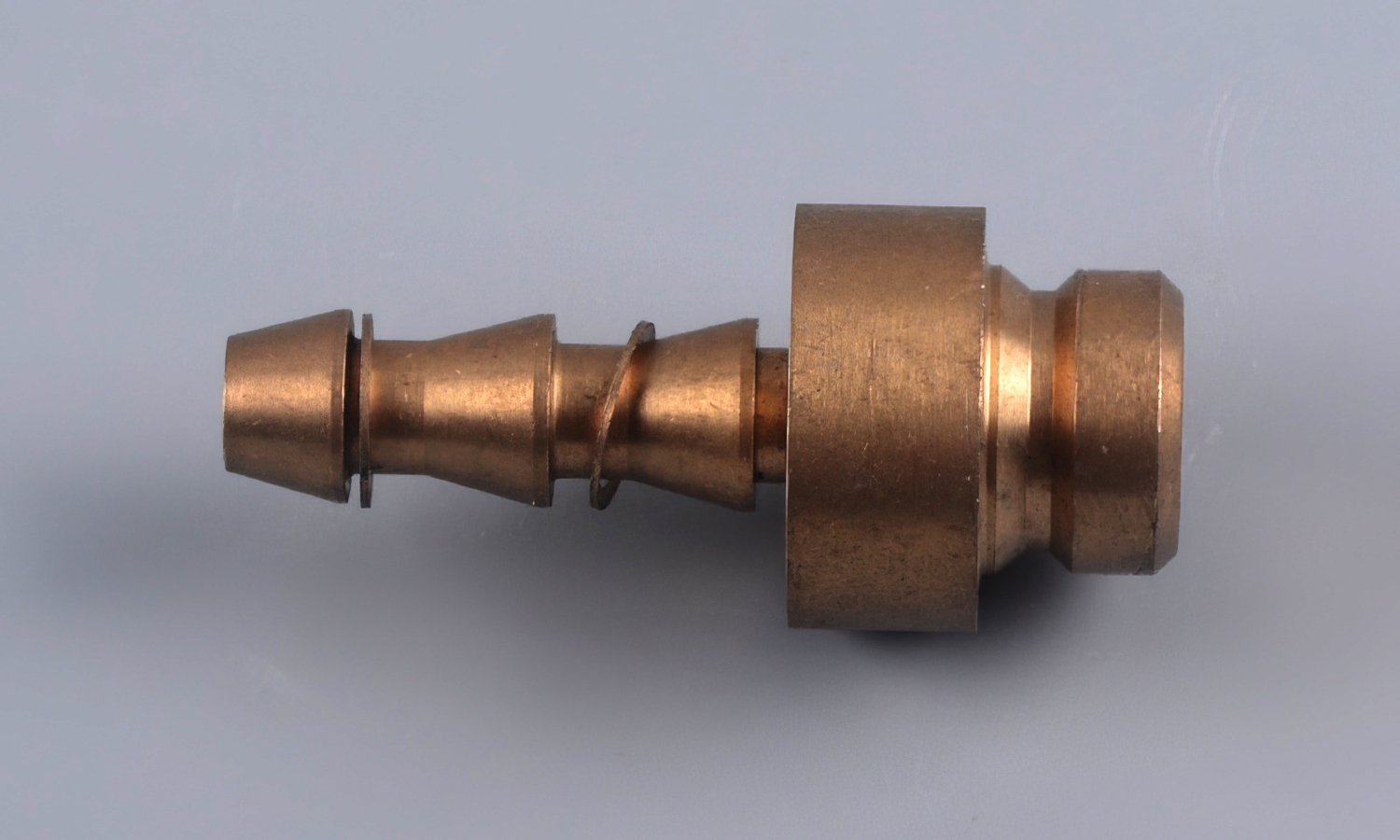

If you need a reliable and versatile hose connector for your fluid transfer applications, you might want to consider CNC milled brass hose tail. This product is a type of hose fitting that has a barbed end that can be inserted into a hose and secured with a clamp or crimped ferrule. The other end has a male or female threaded connection that can be attached to a valve, nozzle, or other device.

It is made of brass, a corrosion-resistant and durable metal that can withstand high temperatures and pressures. Brass also has good conductivity and low magnetic permeability, making it suitable for various media such as water, oil, gas, air, and steam.

A CNC-milled brass hose insert can offer many benefits, such as:

– High precision and accuracy

– Customizable size, shape, and design

– Easy installation and removal

– Leak-proof and secure connection

– Cost-effective and eco-friendly

If you want to customize a CNC milled brass hose barb, you should check out facfox.com. FacFox is a leading online platform that provides metal CNC milling services for various industries. FacFox can help you design, prototype, and produce your brass hose fitting with high quality and fast turnaround. FacFox can also offer you competitive prices, free quotes, and professional support.

Solution

- Step 1: The CAD model was examined and transformed into a CNC-compatible format with the software AutoCAD.

- Step 2: A most suitable type of CNC machine was chosen according to the complexity of the product design and the cost of the workpiece.

- Step 3: Certain operations were configured and the G-codes were input on the machine. The workpiece was mounted on the machine as well.

- Step 4: The workpiece got shaped and the holes were drilled automatically. It would be inspected during and after the machining process for quality assurance.