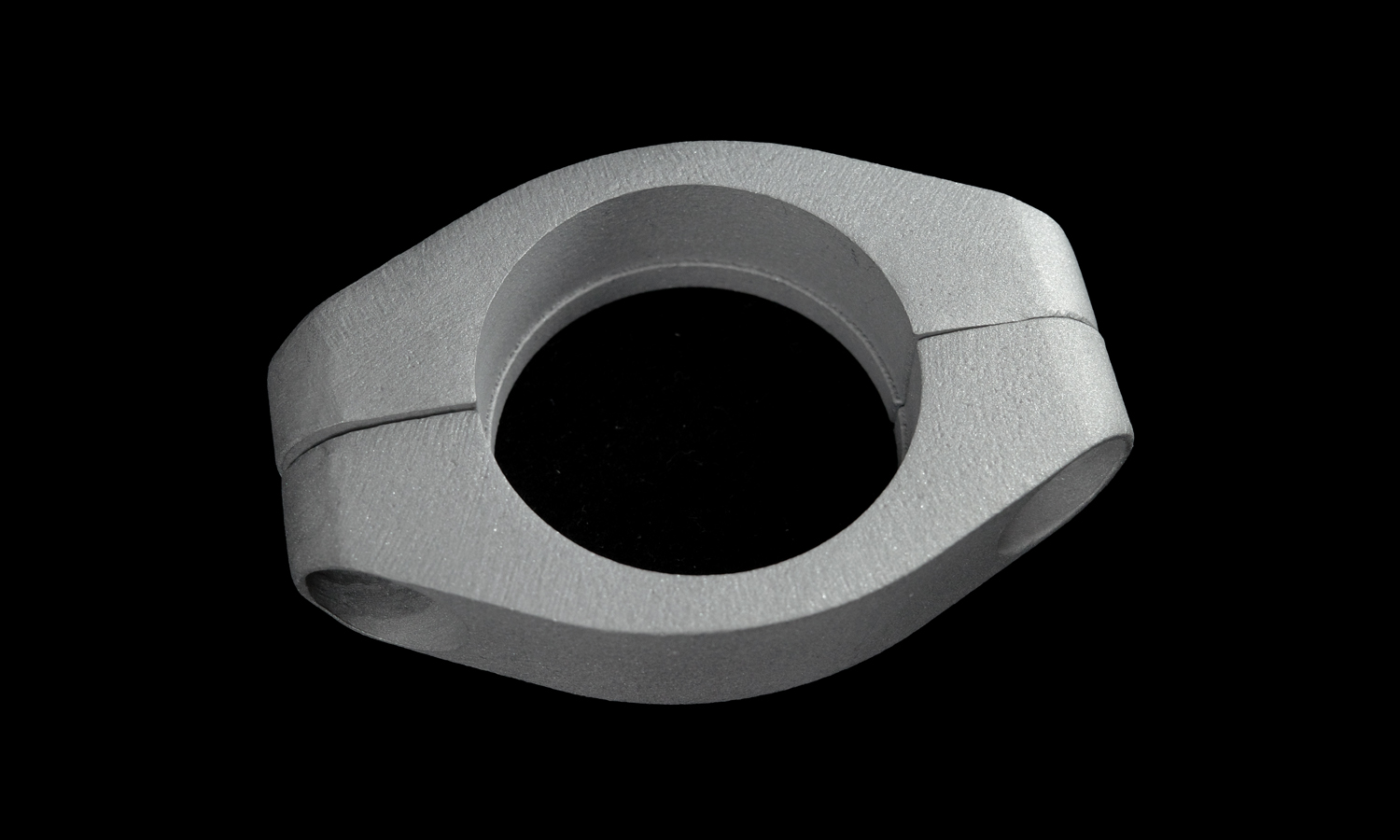

- SLM 3D Printed Aluminum Cylindrical Flange Pipe Connector

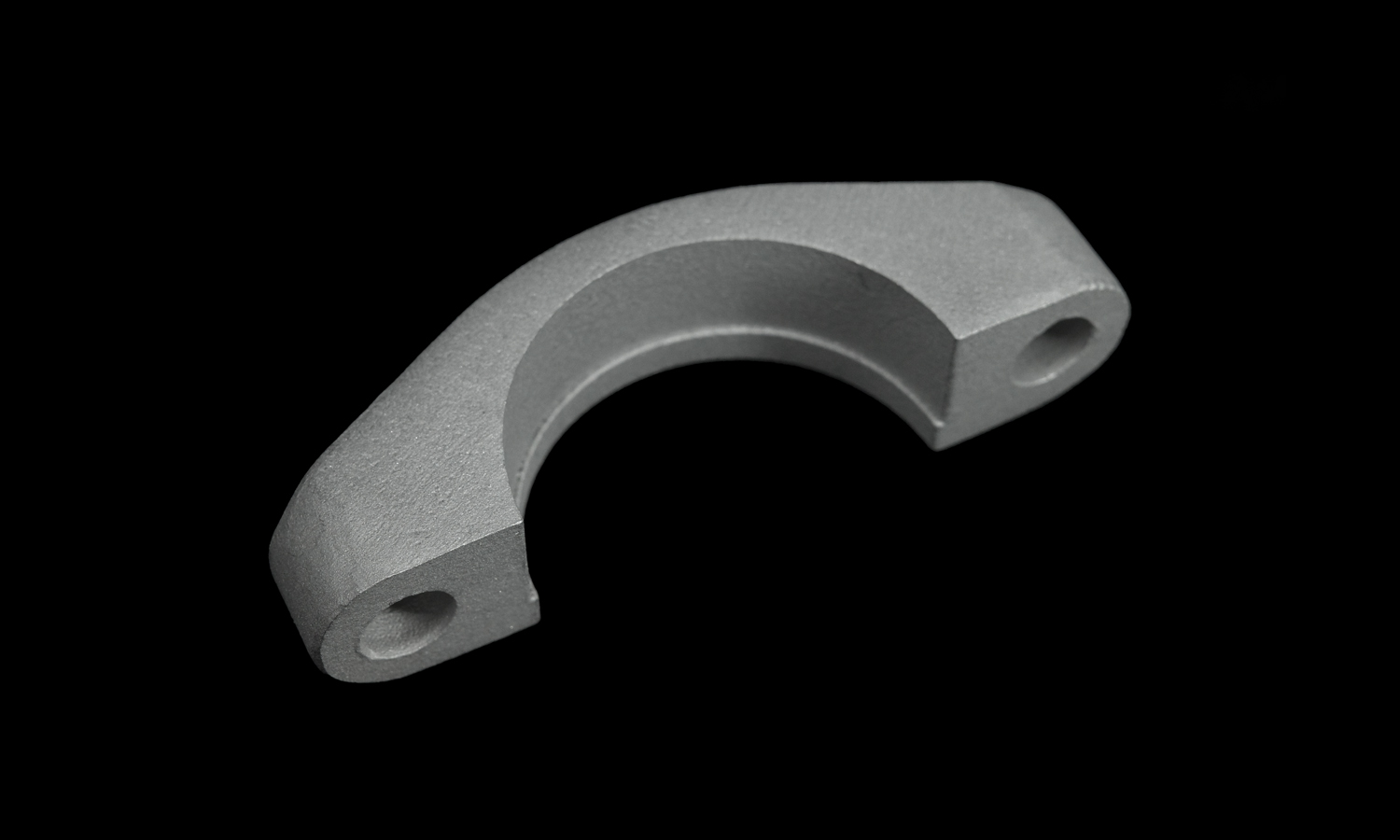

- SLM 3D Printed Aluminum Alloy Saddle Clamps

Gallery

About Project

In the realm of cutting-edge manufacturing, our Selective Laser Melting (SLM) 3D Printed Aluminum Saddle Clamps exemplify the perfect fusion of technology and precision engineering. These custom saddle clamps are meticulously designed to meet the unique specifications of our clients, ensuring top-tier performance and reliability.

Key Features

- Material: Constructed from premium aluminum alloy, known for its lightweight, corrosion-resistant, and strong properties, making it an ideal choice for various mechanical and industrial applications.

- Design: The saddle clamps feature semi-circular cutouts that fit snugly around pipes or cylindrical objects, providing robust support. The holes allow for secure mounting, ensuring the clamps stay firmly in place.

- Customization: These clamps are tailored for a specific client who will further CNC machine the parts. We incorporate an allowance to the model, allowing precise adjustments to meet the desired dimensions. The client will also polish the parts and thread the holes using CNC for a flawless finish.

- Raw Finishing: Before post-processing, the raw finishing of the printed clamps is rough, providing a starting point for further customization and refinement.

Why Choose Our Saddle Clamps?

Our SLM 3D Printed Aluminum Saddle Clamps are designed to offer exceptional support and stability for pipes and cylindrical objects. Their customizable nature and high-quality construction make them suitable for a wide range of applications, from plumbing systems to industrial machinery.

Elevate Your Projects with FacFox’s Metal 3D Printing Service

FacFox stands at the forefront of metal 3D printing, delivering state-of-the-art solutions to bring your designs to life with unmatched precision and efficiency. Our expertise in SLM 3D printing allows us to create high-quality parts tailored to your specific requirements.

From raw finishing to detailed post-processing, we provide comprehensive services to meet your unique needs. Whether you require parts with allowances for CNC machining or intricate designs polished to perfection, FacFox is here to deliver exceptional quality and innovative solutions.

Explore the future of manufacturing with FacFox’s metal 3D printing services and elevate your projects to new heights. Contact us today to learn more about how we can transform your ideas into reality with our cutting-edge technology!

Solution

- Step 1: 3D Model Creation. The initial design for the saddle clamp was created using computer-aided design (CAD) software, incorporating specific client requirements.

- Step 2: SLM 3D Printing. The 3D model was then processed for Selective Laser Melting (SLM) 3D printing. A high-power laser beam was used to selectively melt and fuse layers of aluminum alloy powder, building the clamp layer by layer according to the digital design.

- Step 3: Part Removal. Once the printing process was complete, the finished clamp was carefully removed from the build platform.

- Step 4: Support Structure Removal. Any support structures used during the printing process were removed from the clamp using appropriate methods.