- SLA 3D Printed and Silver-Finished Automotive Transmission Housing Model

- How SLA Clear Resin Captures Color and Light

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

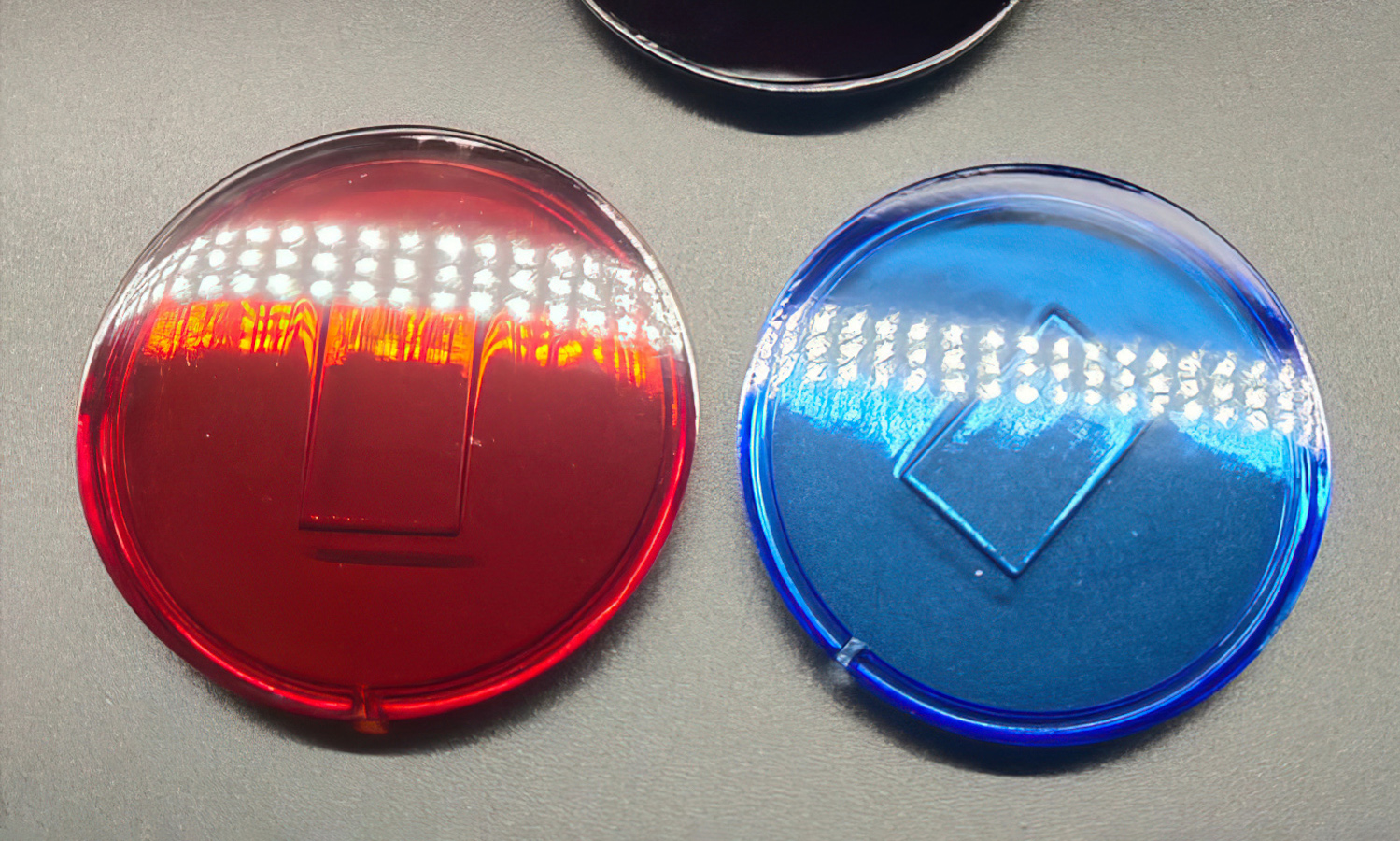

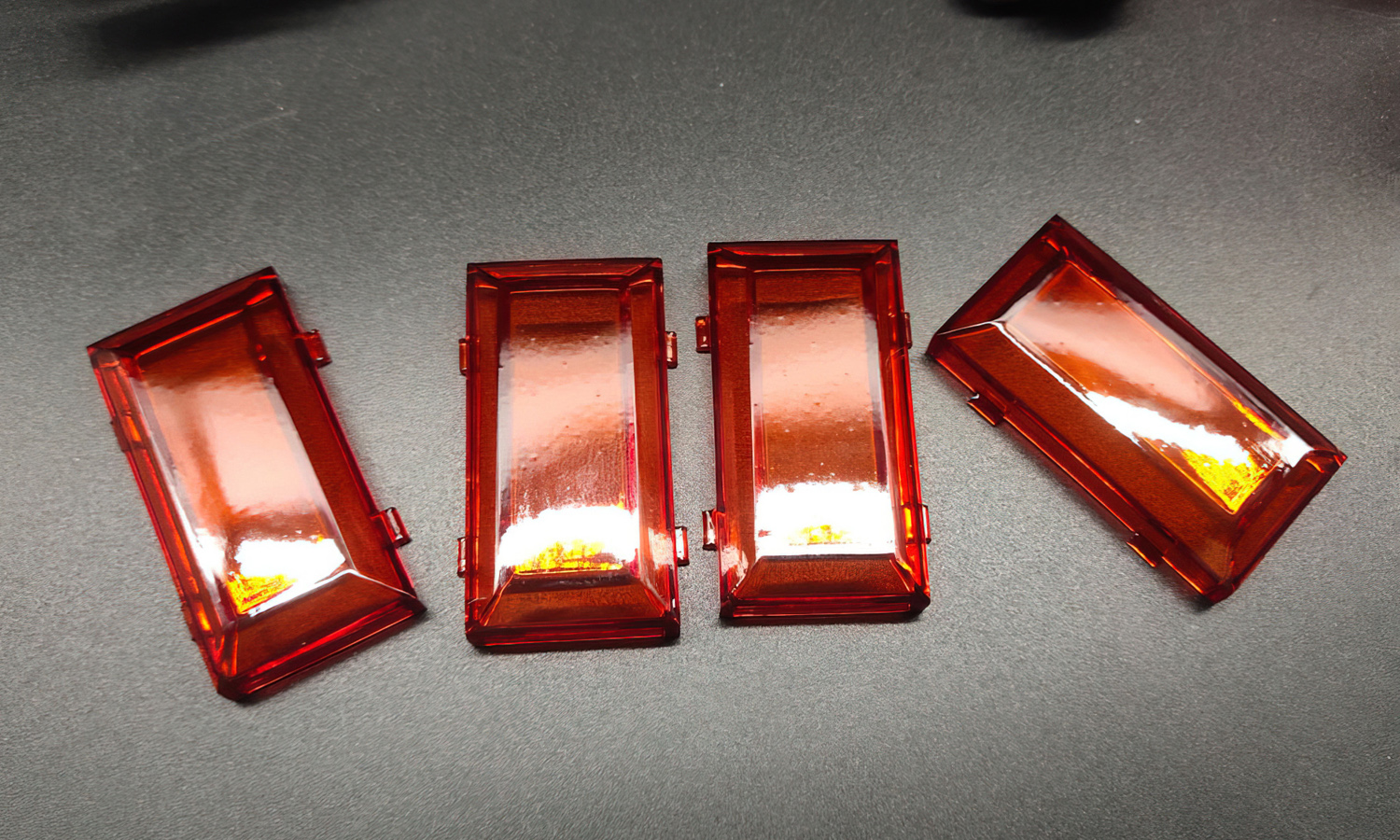

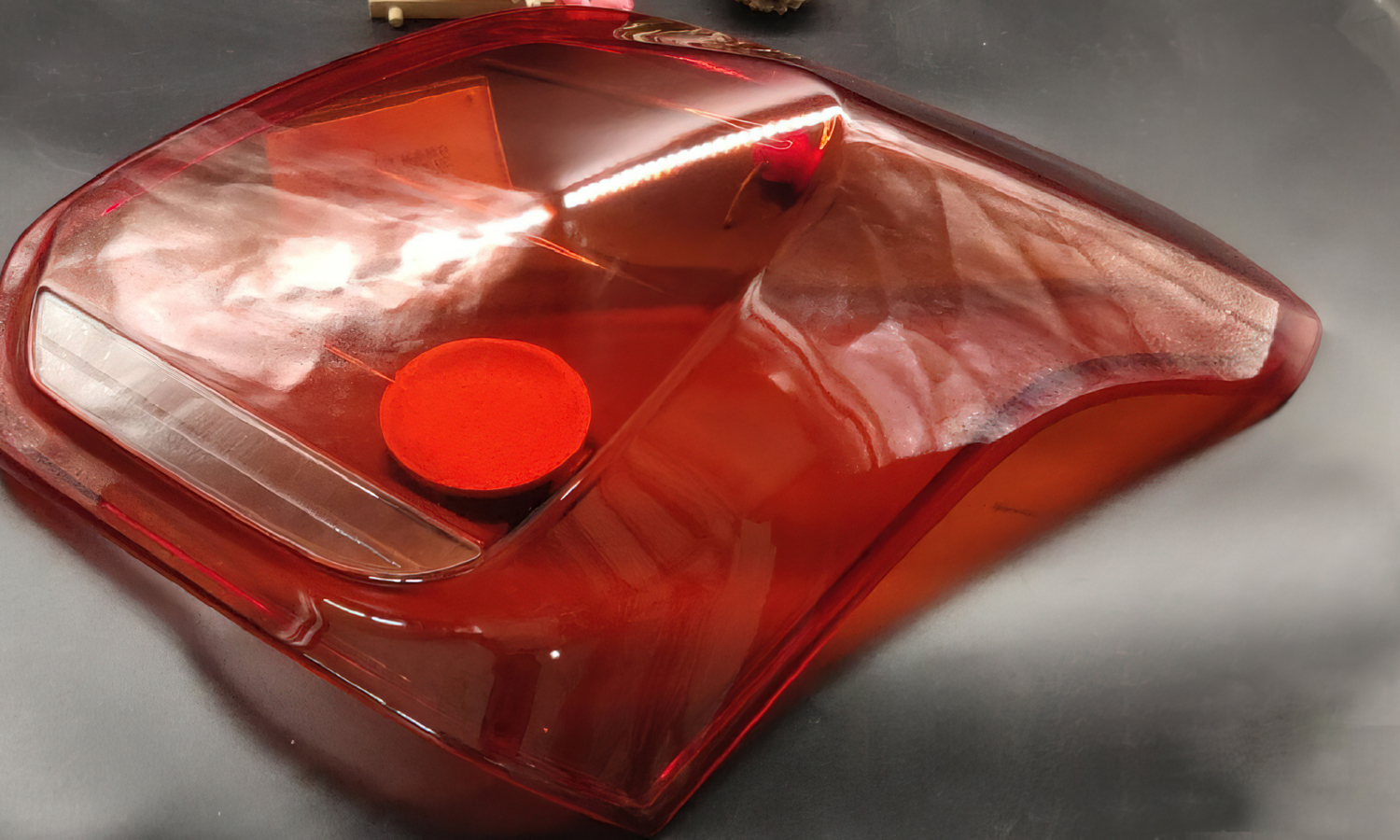

Automotive design demands not only precision but also visual performance. In this case, a series of transparent red components were produced to prototype various car lighting elements – from tail light covers and reflectors to signal lamp housings. These parts were used for design validation and optical testing before the final injection molding stage.

Each piece captures the essence of modern automotive design: smooth curvature, crisp geometry, and highly uniform transparency. The glossy finish and tinted depth make them appear indistinguishable from mass-produced PMMA or PC injection parts. Surface reflections, optical channels, and lens textures were accurately replicated, allowing engineers to evaluate both aesthetic appearance and light diffusion behavior.

Using SLA clear resin, every detail of the CAD model was faithfully reproduced – including subtle alignment clips, reflector micro-patterns, and internal ribs. The resin’s optical clarity enables realistic simulation of LED performance under different lens geometries, which is crucial for achieving the right luminous balance and diffusion pattern in vehicle lighting design.

The prototypes were later tinted in translucent red and amber shades to emulate functional lens covers. After polishing and coating, they achieved excellent optical transmission and a smooth, glass-like surface quality suitable for both presentation and performance evaluation.

FacFox’s SLA clear resin printing empowers automotive designers and engineers to create high-fidelity transparent parts for headlamp and taillight development, indicator covers, and other optical housings. Whether for visual mock-ups, fit checks, or optical testing, our precision resin printing and polishing techniques help you move faster from concept to production with exceptional clarity and dimensional accuracy.

Solution

- Step 1: Model PreparationThe 3D models of the automotive light covers and reflectors were reviewed and optimized for SLA printing. Thin walls and optical surfaces were carefully oriented to minimize layer stepping and improve light transmission.

- Step 2: SLA 3D PrintingThe parts were printed with FacFox’s SLA Clear Resin, using high-resolution settings to ensure smooth surface curves and precise details on the reflector textures and mounting clips.

- Step 3: Support Removal and CleaningAfter printing, the supports were gently removed, and the parts were washed in isopropyl alcohol to clear out any uncured resin. Each surface was inspected to maintain transparency and edge accuracy.

- Step 4: Polishing and TintingThe clear resin prototypes were gradually sanded and polished to restore optical clarity. Then, they were dyed in translucent red and other tones to simulate real automotive lens colors. A protective acrylic coating was applied for gloss and durability.

- Step 5: Final InspectionThe completed prototypes were examined under different lighting conditions to assess transparency, reflection quality, and geometric accuracy. The results closely resembled injection-molded PC or PMMA components, making them ideal for visual and optical testing.