Material Resin, Other

Quantity 1 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

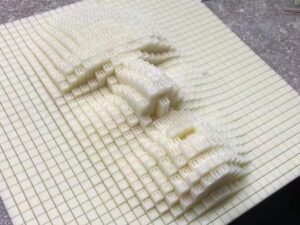

We are thrilled to present our latest creation: a beautifully crafted flower-shaped model featuring five petals and a unique flower-shaped cutout in the middle. This solid model, produced using SLA 3D printing technology, showcases precision and elegance in every detail.

What makes this model truly exceptional is the flocking technique from FacFox. By applying a layer of black fluffs, we’ve enhanced the surface with a rich, velvety texture that is both visually stunning and delightful to touch. This post-processing option elevates the model’s aesthetic and tactile appeal, making it a standout piece.

Why Choose FacFox’s Flocking Technique?

- Enhanced Aesthetics: The flocking adds a sophisticated, plush look to your 3D printed models.

- Tactile Experience: The soft, fuzzy surface is pleasing to touch, making your models stand out.

- Versatility: Ideal for a variety of applications, from decorative items to functional prototypes.

Elevate your 3D printing projects with FacFox’s flocking technique and experience the difference in quality and finish. Whether you’re creating art pieces, jewelry, or intricate designs, our flocking process will give your models the edge they deserve.

Ready to bring your ideas to life? Contact us today to learn more about our 3D printing services and post-processing options!

Solution

- Step 1: Design Creation.┬ĀThe flower model was designed using CAD software, ensuring precise dimensions and the inclusion of the five petals and flower-shaped cutout in the middle.

- Step 2: File Preparation.┬ĀThe CAD file was converted into an STL format, which was then sliced into layers using slicing software to prepare it for 3D printing.

- Step 3: Printer Setup. The SLA 3D printer was calibrated, and the resin tank was filled with SLA Generic Resin.

- Step 4: Printing Process.┬ĀThe sliced file was uploaded to the printer, and the printing process was initiated. The model was built layer by layer as the laser cured the resin.

- Step 5: Post-Processing.┬ĀOnce printing was completed, the model was carefully removed from the build platform and rinsed in isopropyl alcohol to remove any uncured resin.

- Step 6: Curing.┬ĀThe model was placed in a UV curing chamber to ensure that it was fully hardened and the resin was completely cured.

- Step 7: Surface Preparation.┬ĀThe model was inspected for any imperfections, and any necessary sanding or smoothing was performed to prepare the surface for flocking.

- Step 8: Flocking Application.┬ĀThe model was coated with an adhesive, and black fluffs were applied using an electrostatic flocking machine to ensure an even and thorough coverage.

- Step 9: Final Inspection.┬ĀThe flocked model was inspected to ensure the flocking was evenly applied and the texture was consistent across the entire surface.

- Step 10: Packaging.┬ĀThe completed model was carefully packaged to protect the delicate flocked surface during shipping.