Gallery

About Project

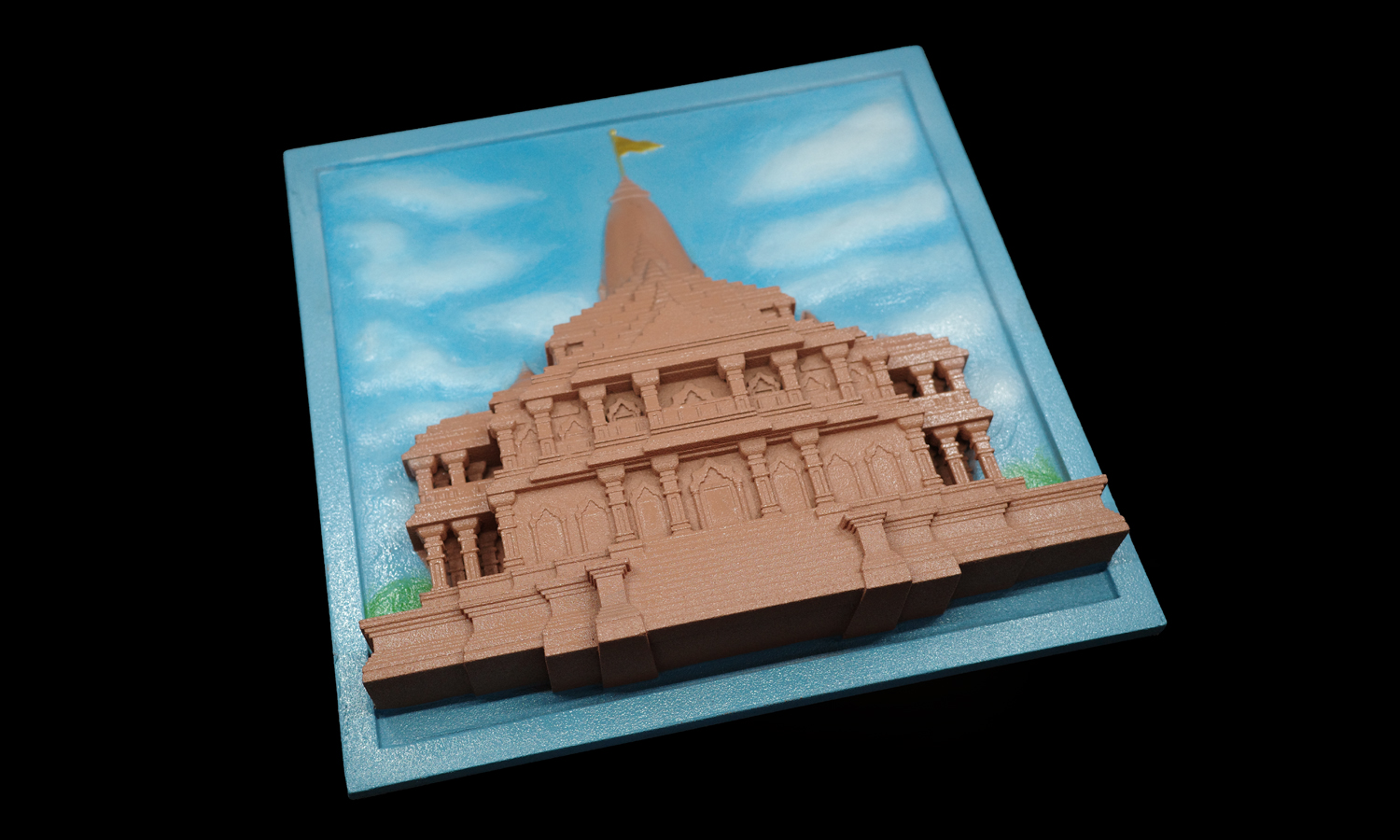

This temple relief was produced using ColorJet 3D printing (CJP sandstone), based on a client’s original 3D model. The print accurately captured the layered geometry of the temple – from the stairways to the domed spire – showcasing the precision and surface fidelity of the sandstone printing process.

The ColorJet method builds parts layer by layer from gypsum-based powder, selectively bonded with liquid adhesive. After depowdering and infiltration, the model was transformed through a hand-painted color test, exploring a more naturalistic palette compared to the single-tone orange version.

Painting & Finishing

This iteration introduced a multicolor scheme: a warm reddish-brown tone for the temple body, complemented by a soft blue sky background, white cloud highlights, and green base accents. A small yellow flag atop the spire adds a vivid focal point.

Unlike the earlier glossy version, the paint here was applied in multiple light coats, resulting in a smoother and more uniform surface without obscuring fine details. The matte texture preserved the crisp architectural features while providing a realistic stone-like finish.

The success of this test highlights the importance of controlled coating thickness and gradual color layering for achieving both visual depth and material authenticity in sandstone 3D prints.

3D Printing with FacFox

At FacFox, we specialize in ColorJet sandstone 3D printing for decorative art, architectural miniatures, and cultural replicas. Our team provides professional post-processing, including sealing, painting, and protective finishing, ensuring your models achieve both accuracy and artistry. Whether you’re prototyping, displaying, or creating custom decor, FacFox helps bring your digital designs to life with exceptional craftsmanship.

Bring your creative vision to life with FacFox’s sandstone 3D printing and finishing expertise.

Solution

- Step 1: The client’s 3D model of the temple relief was prepared and optimized for ColorJet printing.

- Step 2: The file was sliced and printed using the CJP sandstone process, where gypsum-based powder was bound layer by layer with adhesive.

- Step 3: After printing, the part was depowdered carefully to remove excess material from the fine details.

- Step 4: The model was infiltrated with cyanoacrylate to increase strength and color depth.

- Step 5: The surface was sealed and primed to create a uniform painting base.

- Step 6: Multiple thin coats of reddish-brown, blue, white, green, and yellow paint were applied with an airbrush to achieve balanced color transitions.

- Step 7: A matte clear coat was sprayed to protect the paint layer and maintain a realistic sandstone texture.

- Step 8: The finished model was inspected, cleaned, and packaged for delivery.