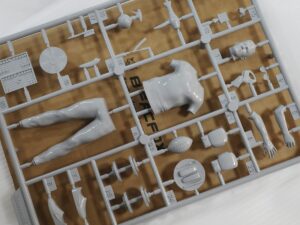

- Mimaki 3D Printed Full-color Pink Dress Girl Scaled-down Figure

- SLA 3D Printed Male Figure Model Kit Wall Decoration

Gallery

About Project

At FacFox, we're excited to showcase our full-color 3D printing services! Today, we spotlight ColorJet printing technology, featuring a charming scaled-down figure of a girl in a pink dress.

Built for Stability and Color

For stability, ColorJet prints employ a 2mm wall thickness with internal support, ensuring a sturdy final product. The figure stands at 101.6mm and weighs a lightweight 23.1g.

ColorJet excels in vibrant color output. The dress and lips showcase high saturation for a stunning visual impact. However, this can lead to some color bleed, resulting in a slight tint on areas like the arms and legs.

Balancing Color with Detail

ColorJet has a larger minimum layer height compared to other technologies, leading to more visible layer lines. This is mitigated by the matte finish, creating a pleasant overall appearance.

Important Considerations

- Finer details: The circular patterns on the girl's top may appear as a mix of gray and white dots.

- Subtle features: Pupils and whites of the eyes might be slightly blurred due to layer lines.

The ColorJet Advantage

While detail may be slightly diminished, ColorJet shines in producing eye-catching, vibrant colors. This technology is ideal for projects where bold colors are the priority, particularly cost-effective, making it the most affordable option among our full-color printing services.

Turn Your Vision into Reality

Let FacFox be your partner in creating stunning, colorful models. Explore the possibilities! Click here to compare all four of our full-color printing technologies and see which best suits your needs.

Solution

- Step 1: The model was downloaded from the Internet and exported into an STL file for printing.

- Step 2: The manufacturing process began with the spreading of the core material in thin layers over the build platform by a roller.

- Step 3: Once each layer was spread, a color binder was selectively jetted from inkjet print heads, which caused the core to solidify.

- Step 4: The build platform was then lowered to allow the next layer to be spread and printed.

- Step 5: This sequence was repeated, layer by layer, until the full-color three-dimensional model was formed.