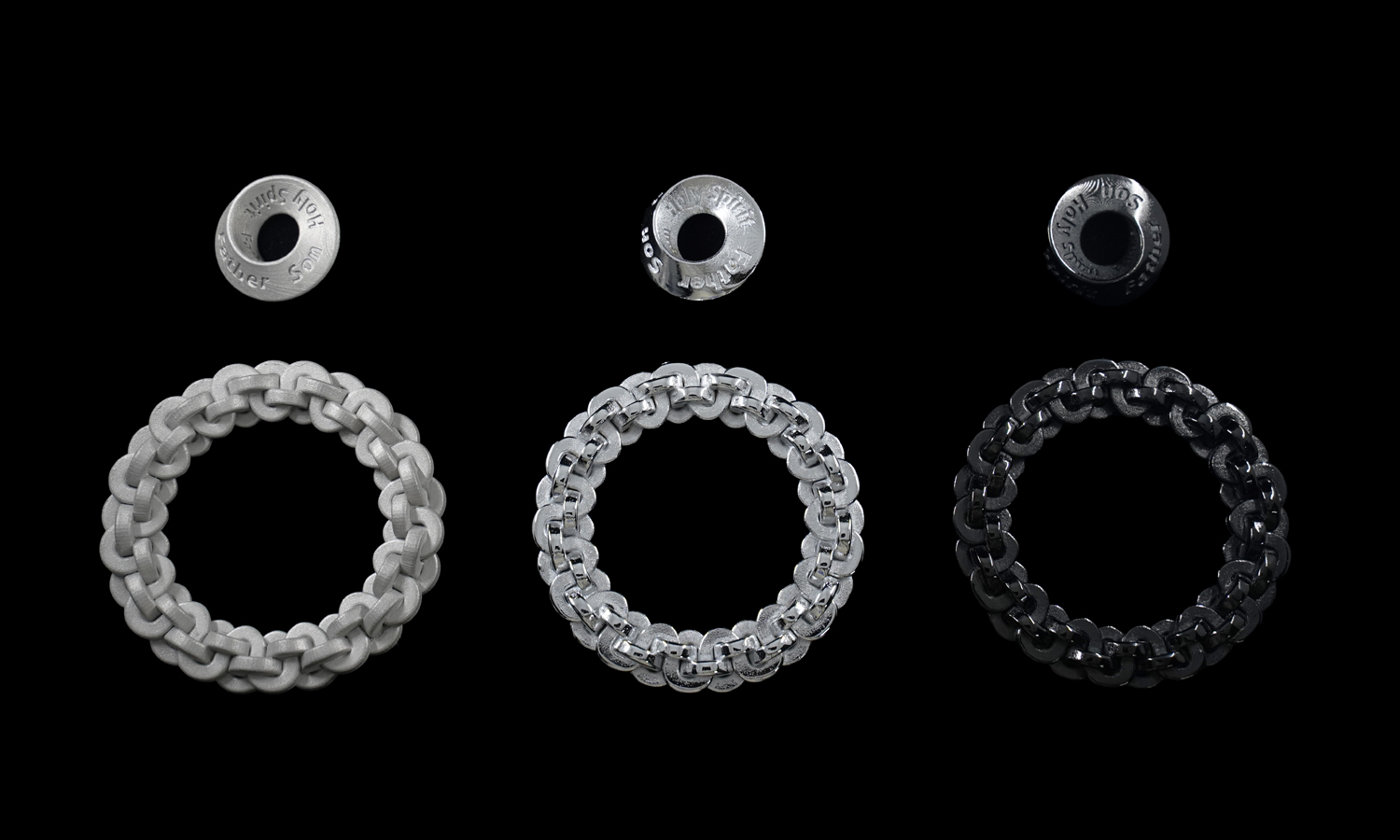

Binder Jet 3D Printed and Electroplated Stainless Steel 316L Chain Circles

- SLS 3D Printed PA12 Black Nylon Sample Parts

- SLM 3D Printed and Unpolished Stainless Steel 316L Sample Parts

Posted on 2023-02-01 in Art бЇ Х┴╨Ф°╞

Process 3D Print, Post Curing, Polish, Electroplate

Material Metal

Quantity 6 pcs

Price Range $100-1,000

Lead Time 5 workdays

Material Metal

Quantity 6 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

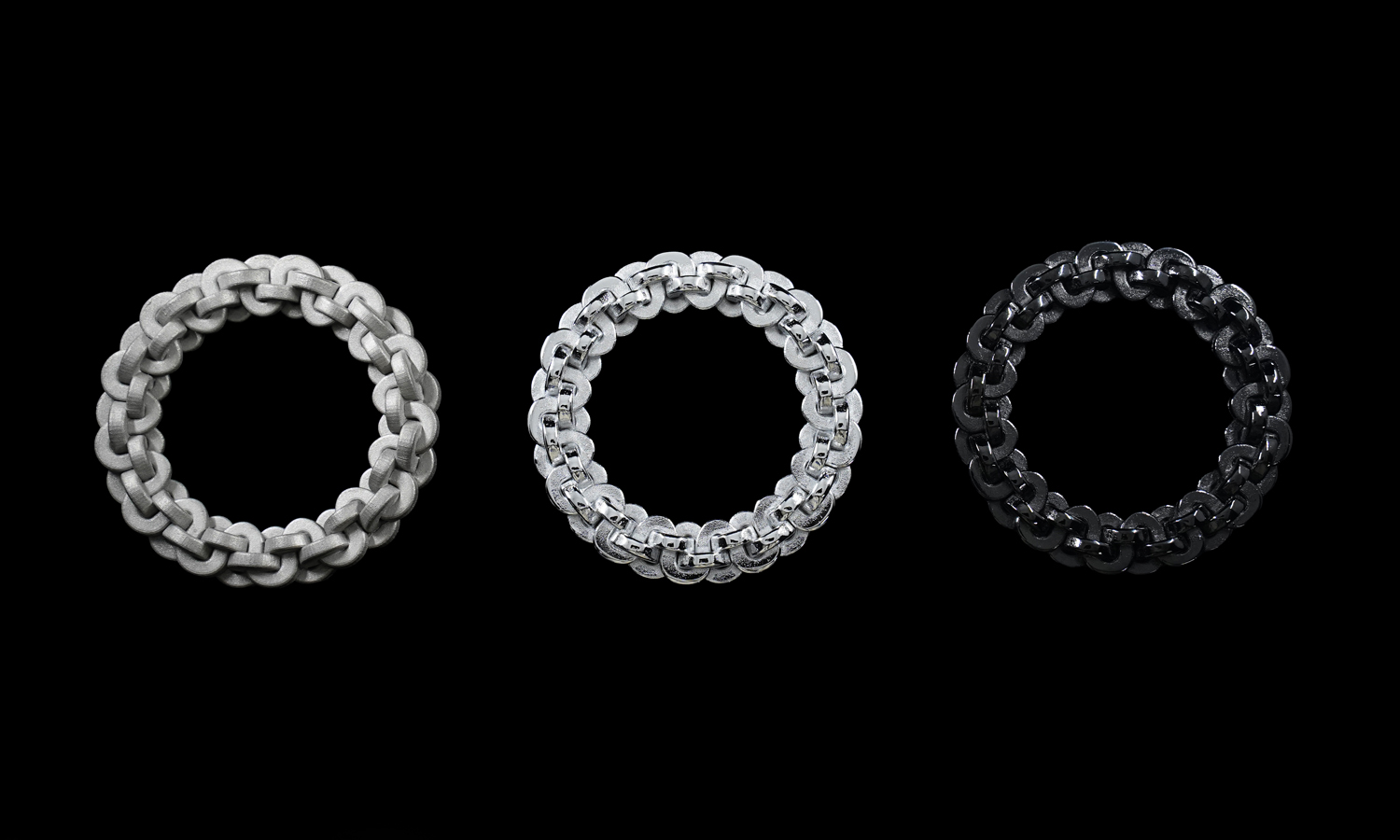

Here are three 3D-printed stainless steel 316L chain circles with different surface effects – the raw finish, electroplated silver, and PVD-plated black. Binder Jet 3D printed parts could be strengthened with some post-processing techniques, including curing, sintering, infiltration, polishing and plating. The metal materials could be much stronger and more durable than their green stage.

Solution

- Step 1: After confirming the requirements with the client, the chain circles were suggested to be printed with binder jetting technology and stainless steel powder.

- Step 2: In metal binder jetting, a liquid binder was selectively applied to join powder particles, layer by layer. The process began by spreading a thin layer of powder, with printheads strategically depositing droplets of binder into the powder bed. The printing plate was then lowered and another layer of powder was spread.

- Step 3: When printing was completed, the extra material was removed for recycling. Cleaned the surface of the model with compressed air. There were no supports that need to be removed.

- Step 4: To achieve high density, the part needed to be post-sintered or infiltrated to fill the voids left by the binding agent being burnt away. Bronze infiltration of stainless steel could achieve a final density of 95%.

- Step 5: Smoothened the surface with electrolytic polishing technique and coated them into silver and black with electroplating and PVD (Physical Vapor Deposition).