- PolyJet 3D Printed Girl Friends Full-color Miniature Memory Gift

- DMLS 3D Printed Titanium Tobacco Pipe with Colorful Glass Tube

Material Resin

Quantity 4 pcs

Price Range $1,000-5,000

Lead Time 14 workdays

Gallery

About Project

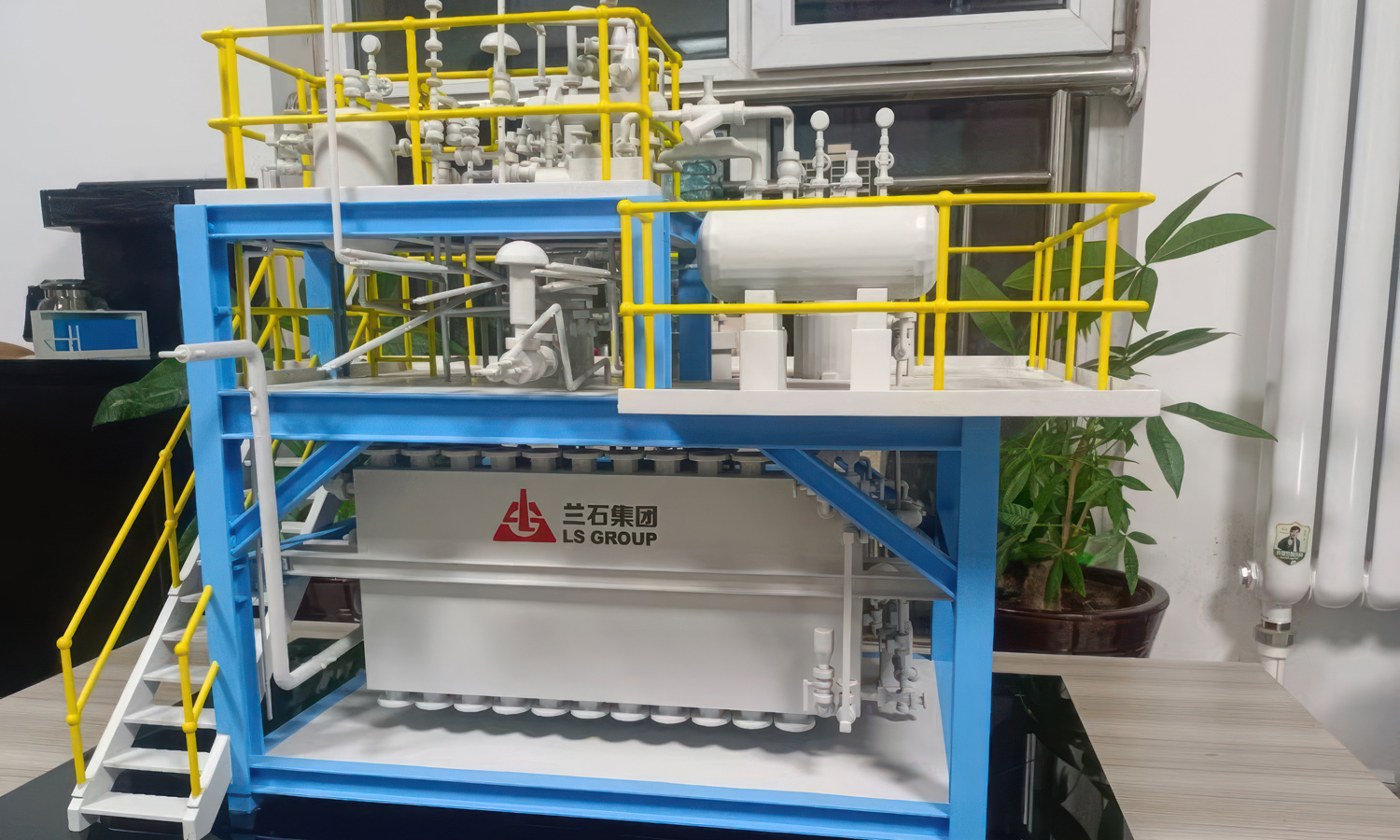

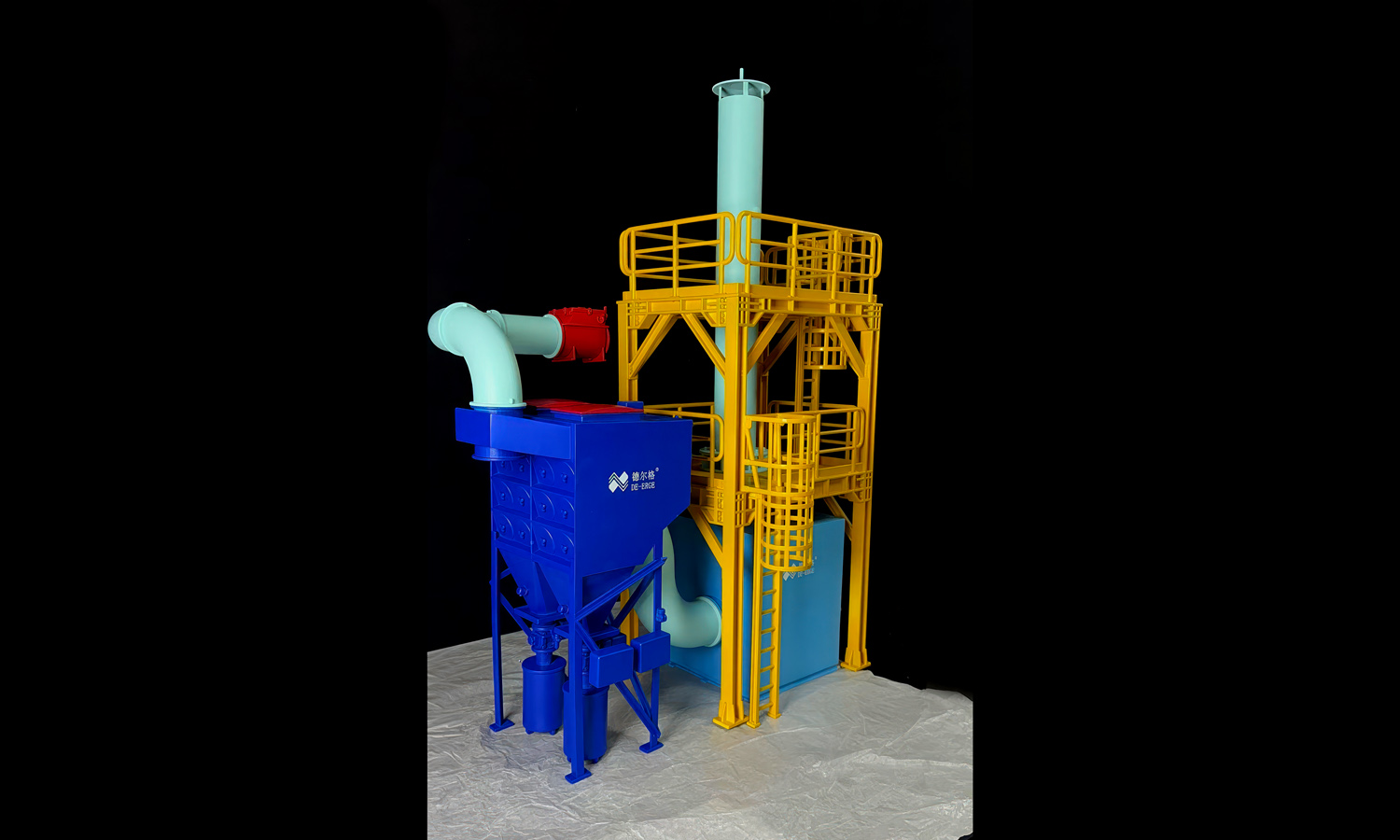

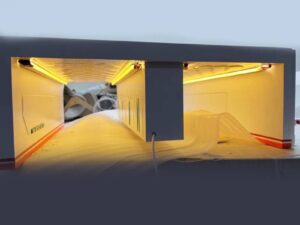

FacFox takes industrial facility visualization to the next level with our high-precision SLA 3D printing service. Imagine showcasing scaled-down replicas of your factories, refineries, or power plants in stunning detail, complete with custom color schemes.

Unmatched Accuracy for Complex Designs:

SLA printing excels at capturing intricate details, making it perfect for replicating industrial facilities. We can produce models featuring:

- Main tanks: Smooth, high-resolution surfaces for a realistic representation.

- Detailed frameworks: Precise printing ensures accurate portrayal of support structures.

- Pipelines: Even the most intricate networks of pipes are captured with exceptional fidelity.

- Stairs and railings: Fine details like these add a touch of realism to your display model.

Built to Handle Overhangs and Small Features:

Our 3D printing expertise tackles challenging industrial designs. We can handle:

- Overhang structures: Our advanced printing techniques ensure these elements print perfectly without collapsing.

- Small details: No component is too intricate for our high-resolution printers.

A Display Model Tailored to You:

Showcase your facility’s unique identity with a custom color scheme. Choose from a wide range of colors to match your branding or highlight specific sections of the model.

Multiple Models, Seamless Process:

FacFox streamlines the creation of multiple display models. With similar structures across your facility variations, we can ensure consistency while incorporating your desired color customizations.

Why Choose FacFox?

- Exceptional detail and accuracy: SLA printing delivers a photorealistic representation of your industrial facility.

- Expert handling of complex designs: Our experienced team ensures flawless printing of overhangs and intricate features.

- Customization options: Tailor your display model with unique color schemes.

- Efficient multi-model production: FacFox offers a streamlined process for creating multiple scaled-down models.

Contact FacFox today and turn your industrial vision into a captivating display model! Let’s discuss your project and bring your facility to life in miniature form.

Solution

- Step 1: Design Creation. The designs for the four different facility models were created using CAD software. Each model featured similar structures, including a main tank, framework, pipeline, and stairs.

- Step 2: File Preparation.┬ĀThe CAD files were converted into STL format and then imported into the SLA 3D printer’s slicing software. The models were oriented to minimize the need for supports and to ensure optimal printing quality.

- Step 3: Support Generation.┬ĀSupports were automatically generated by the slicing software to stabilize overhang structures and small details during the printing process.

- Step 4: Resin Selection.┬ĀDifferent colored resins were selected for each model to achieve the desired color schemes. The resins were loaded into the SLA 3D printer’s resin tank.

- Step 5: Printing.┬ĀThe SLA 3D printer used a UV laser to cure the liquid resin layer by layer. The build platform descended incrementally, allowing each new layer of resin to be cured and solidified. This process continued until the entire model was printed.

- Step 6: Support Removal.┬ĀOnce printing was completed, the models were carefully removed from the build platform. The supports were then detached using specialized tools to avoid damaging the delicate structures.

- Step 7: Cleaning.┬ĀThe printed models were cleaned in an isopropyl alcohol bath to remove any uncured resin. This step ensured that the models were free of any sticky residue.

- Step 8: Post-Curing.┬ĀThe cleaned models were placed in a UV curing chamber to further harden the resin and improve the mechanical properties of the models.

- Step 9: Finishing.┬ĀAny remaining support marks were sanded down, and the models were polished to achieve a smooth surface finish. Additional details, such as painting or decals, were applied as needed to enhance the appearance of the models.

- Step 10: Quality Inspection.┬ĀEach model underwent a thorough quality inspection to ensure that all details were accurately reproduced and that the models met the required standards.

- Step 11: Packaging.┬ĀThe finished models were carefully packaged to protect them during transportation and storage.