- FDM 3D Printed Ocean Waves Wall Decoration Artwork

- SLA 3D Printed Hellbound Channard Cenobite Resin Garage Kit

Gallery

About Project

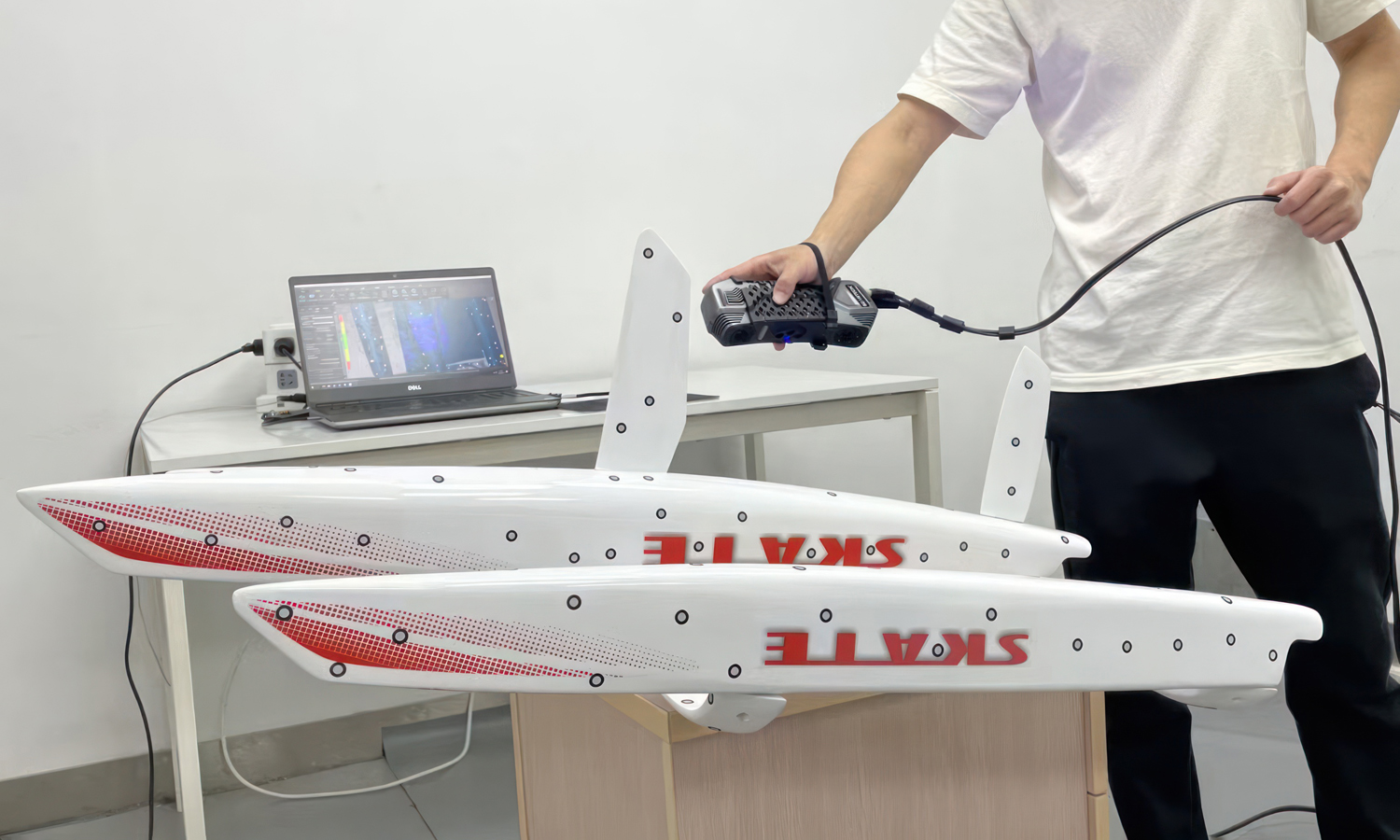

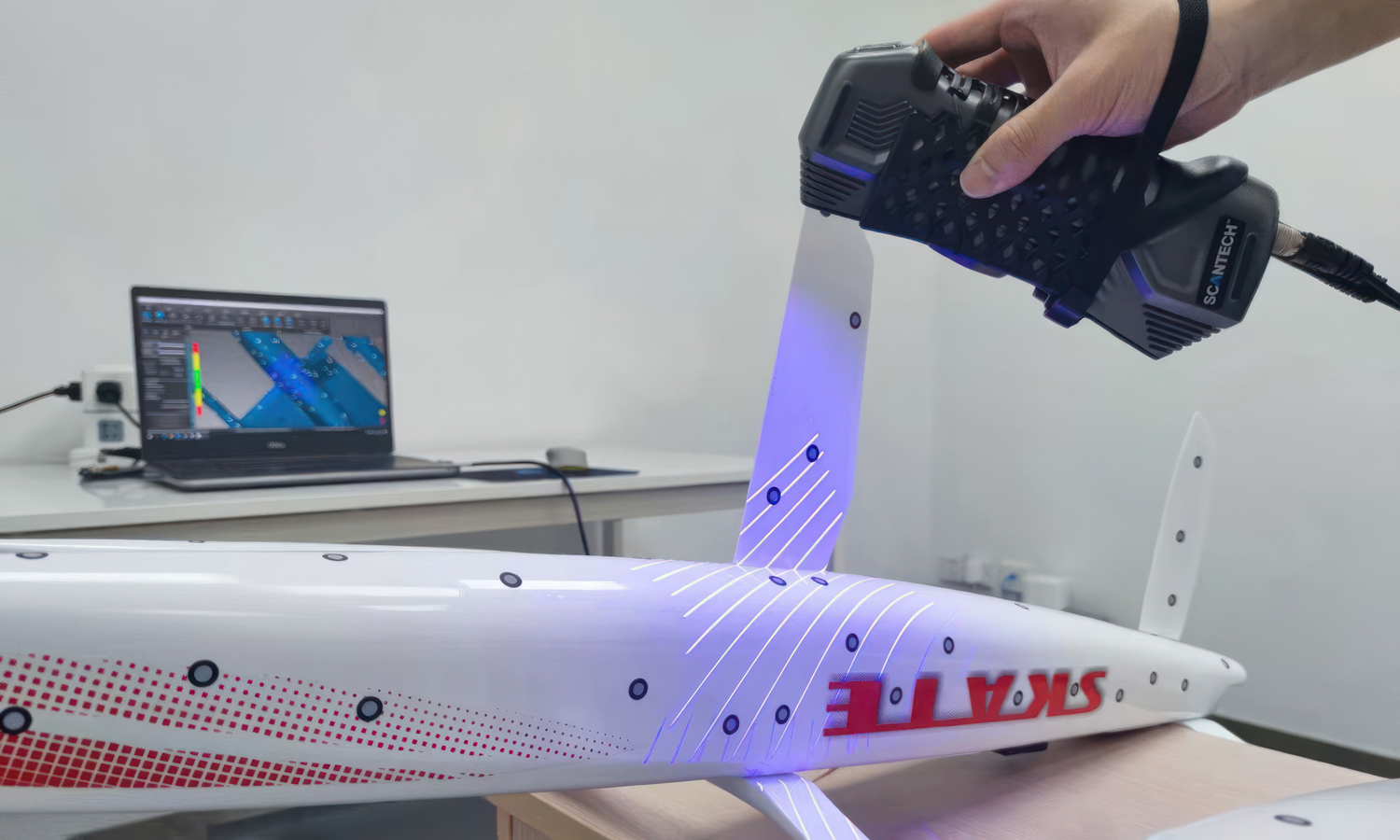

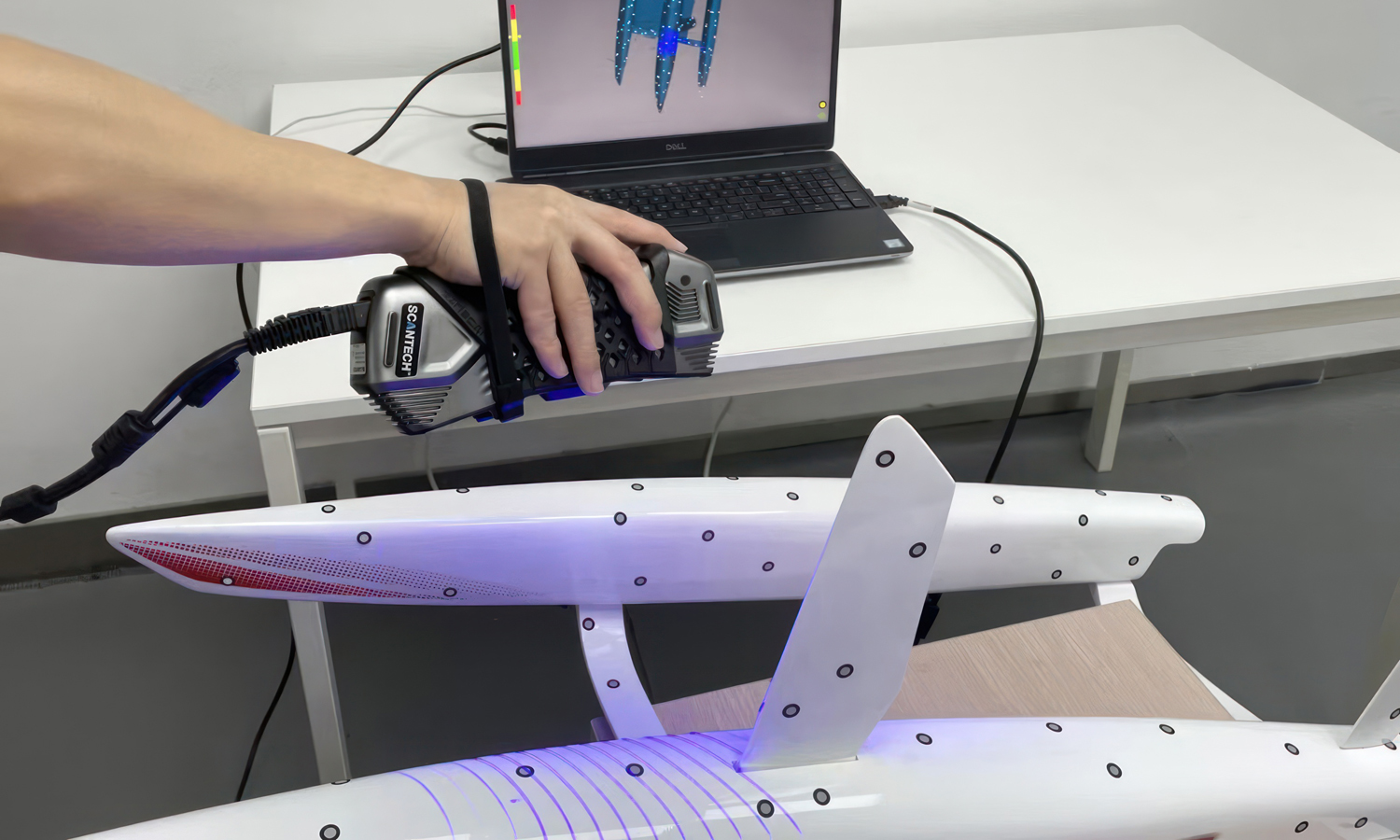

In the world of aerospace innovation and UAV development, precision is everything. The model aircraft shown here-marked with “SKATE” and dotted with photogrammetric targets-is undergoing high-precision 3D scanning using a handheld structured light scanner. This sleek, composite-body UAV model is being digitally captured in full detail to aid in reverse engineering and performance optimization.

Why Scan a Model Aircraft?

Reverse engineering allows engineers to reconstruct accurate CAD models from existing physical objects. Whether you’re upgrading an old design, replicating a prototype without drawings, or verifying structural dimensions, 3D scanning bridges the physical and digital worlds seamlessly.

What Is Handheld 3D Scanning?

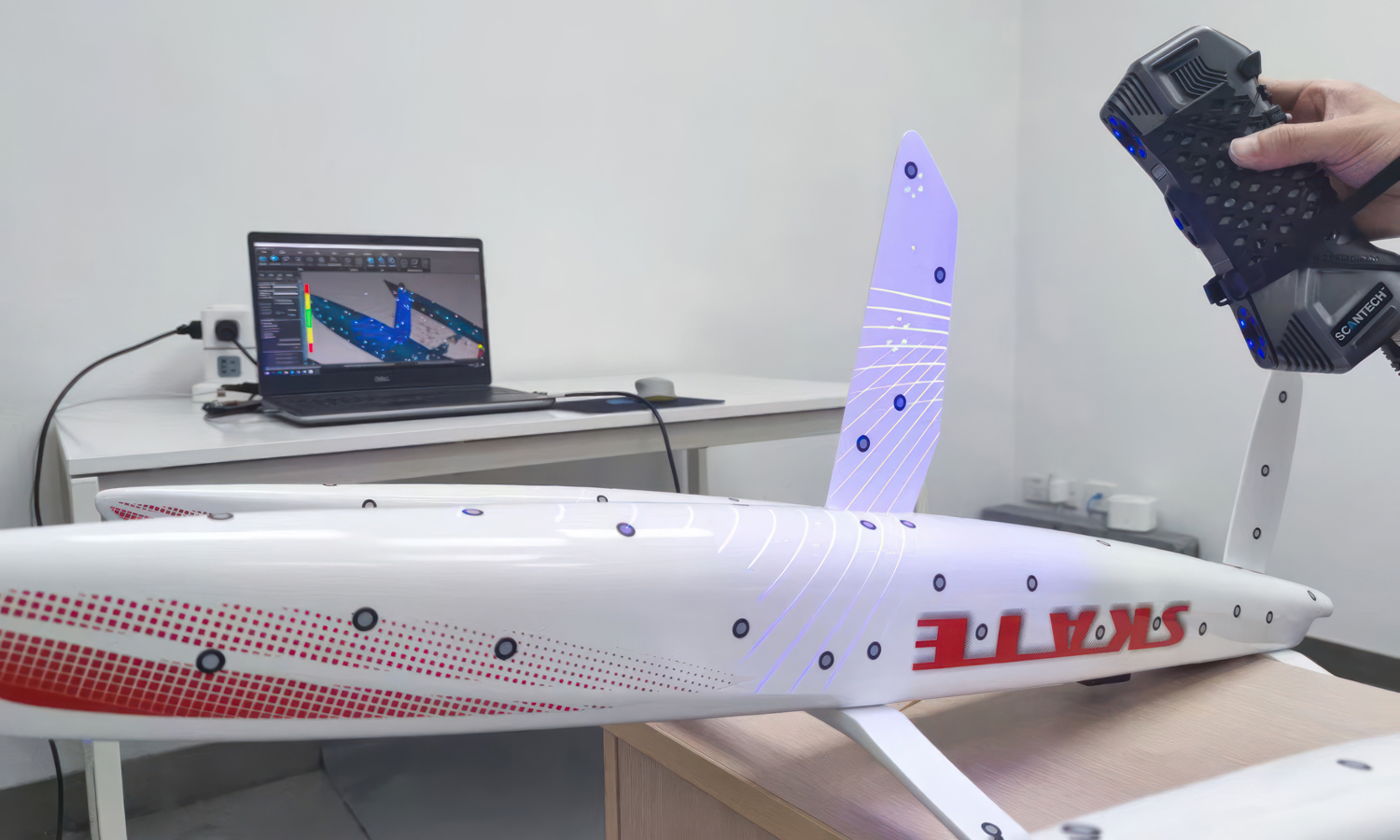

Handheld 3D scanning uses structured light or laser projection to map the surface geometry of an object in real-time. The scanner projects a grid or stripe pattern (seen here as blue-white lines) while internal cameras detect the distortion of the pattern over the surface. Reference markers placed on the model help the scanner track its position with high accuracy-often down to microns.

Unlike fixed systems, handheld scanners offer unmatched mobility and flexibility, especially for capturing large or complex geometries like aircraft fuselages, wings, or integrated control surfaces.

What Happens After Scanning?

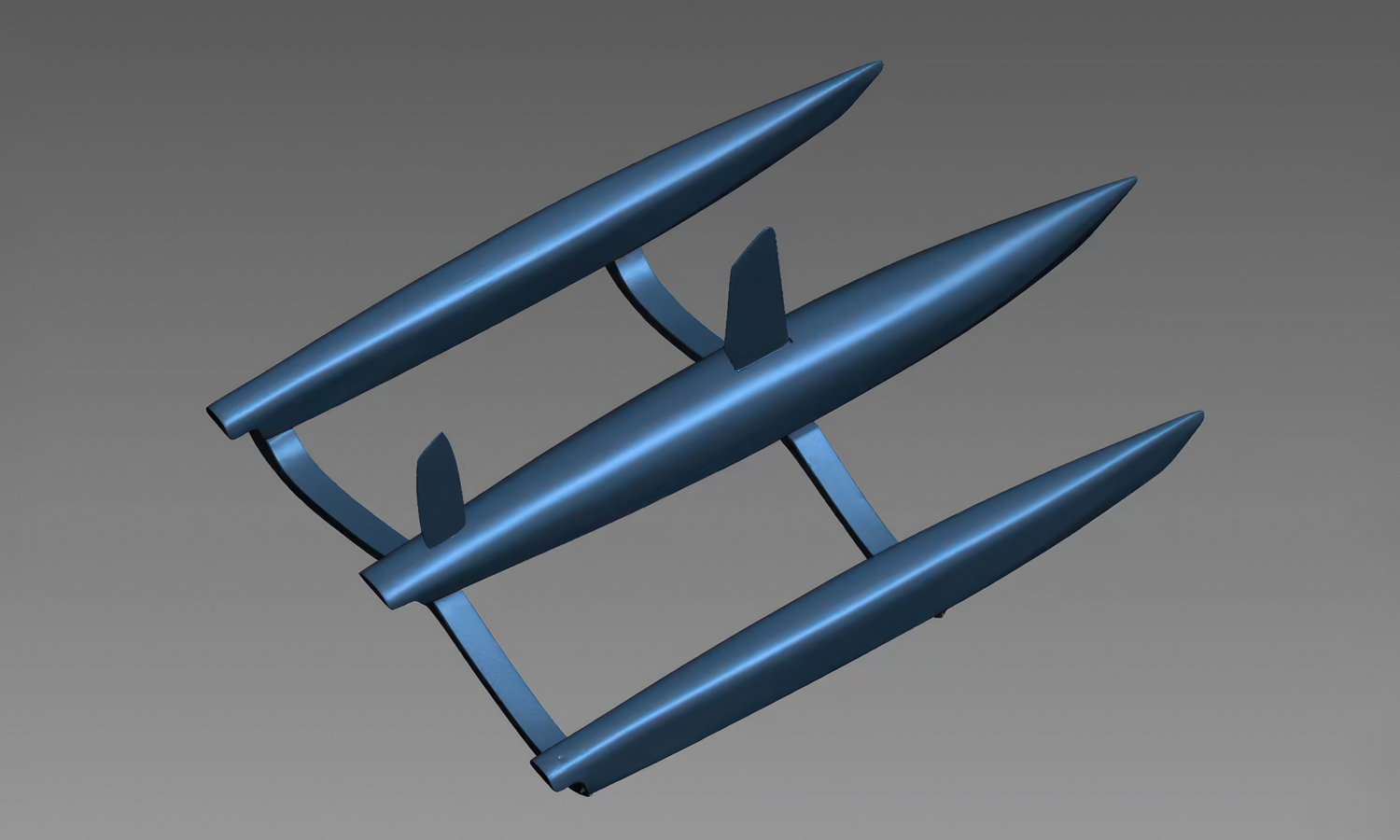

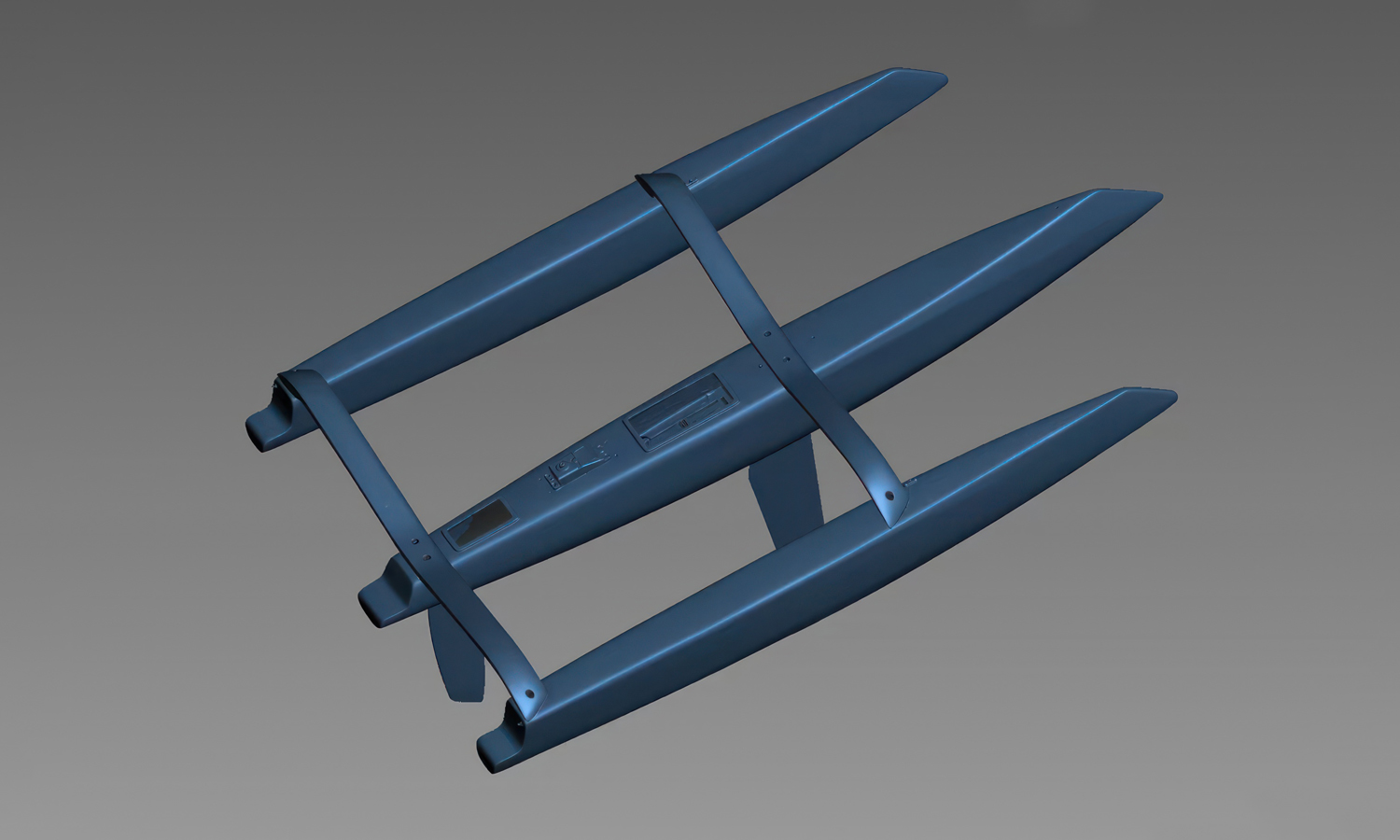

The raw scan data is processed into a dense mesh, which can then be:

- Converted into solid CAD geometry for digital analysis or redesign

- Compared with original CAD for deviation and tolerance checks

- Used for CFD simulations or 3D printing of parts

Need 3D Scanning or Reverse Engineering?

At FacFox, we offer professional handheld 3D scanning and reverse engineering services for model aircraft, UAVs, industrial components, and more. Our scanning solutions are perfect for prototyping, inspection, and legacy part digitization.

Note: At the moment, we only accept 3D scanning requests within mainland China.

Whether you’re looking to modernize an old design or extract valuable data from a complex shape, our experts are here to help. Contact us today and unlock the full potential of your physical prototypes with FacFox’s precision scanning services.

Solution

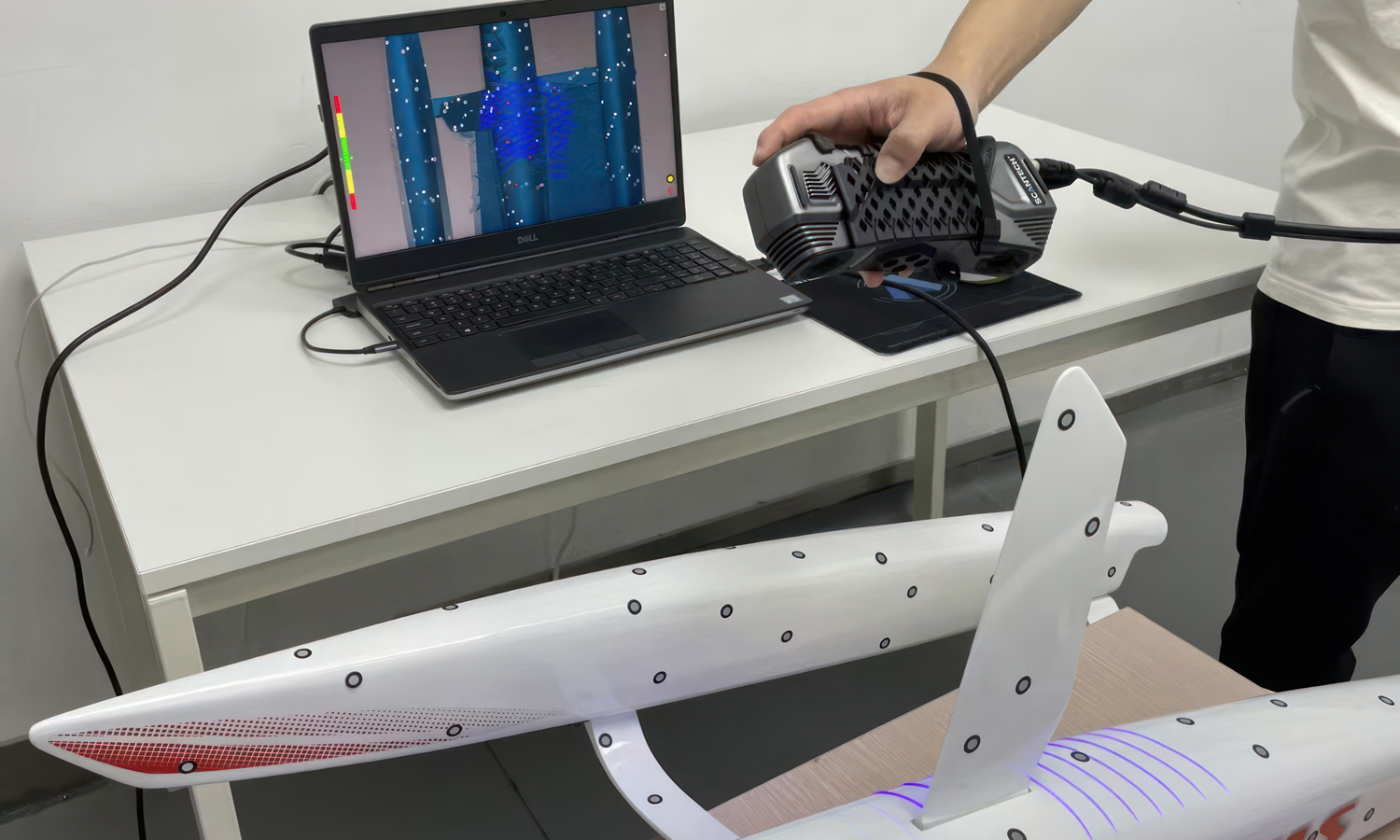

- Step 1: Reference markers were applied evenly across the surface of the model aircraft to assist with spatial tracking and ensure accurate alignment during scanning.

- Step 2: A handheld structured light 3D scanner was calibrated and prepared for scanning. The scanning environment was adjusted to minimize ambient light interference.

- Step 3: The surface of the aircraft was scanned manually, with the scanner capturing millions of data points as it was moved around the body, wings, and tail.

- Step 4: The scanned data was streamed in real-time to a connected workstation, where a point cloud was generated and visually monitored for completeness.

- Step 5: The point cloud data was processed into a high-resolution mesh using specialized software. Any noise or artifacts were removed, and missing areas were filled using interpolation techniques.

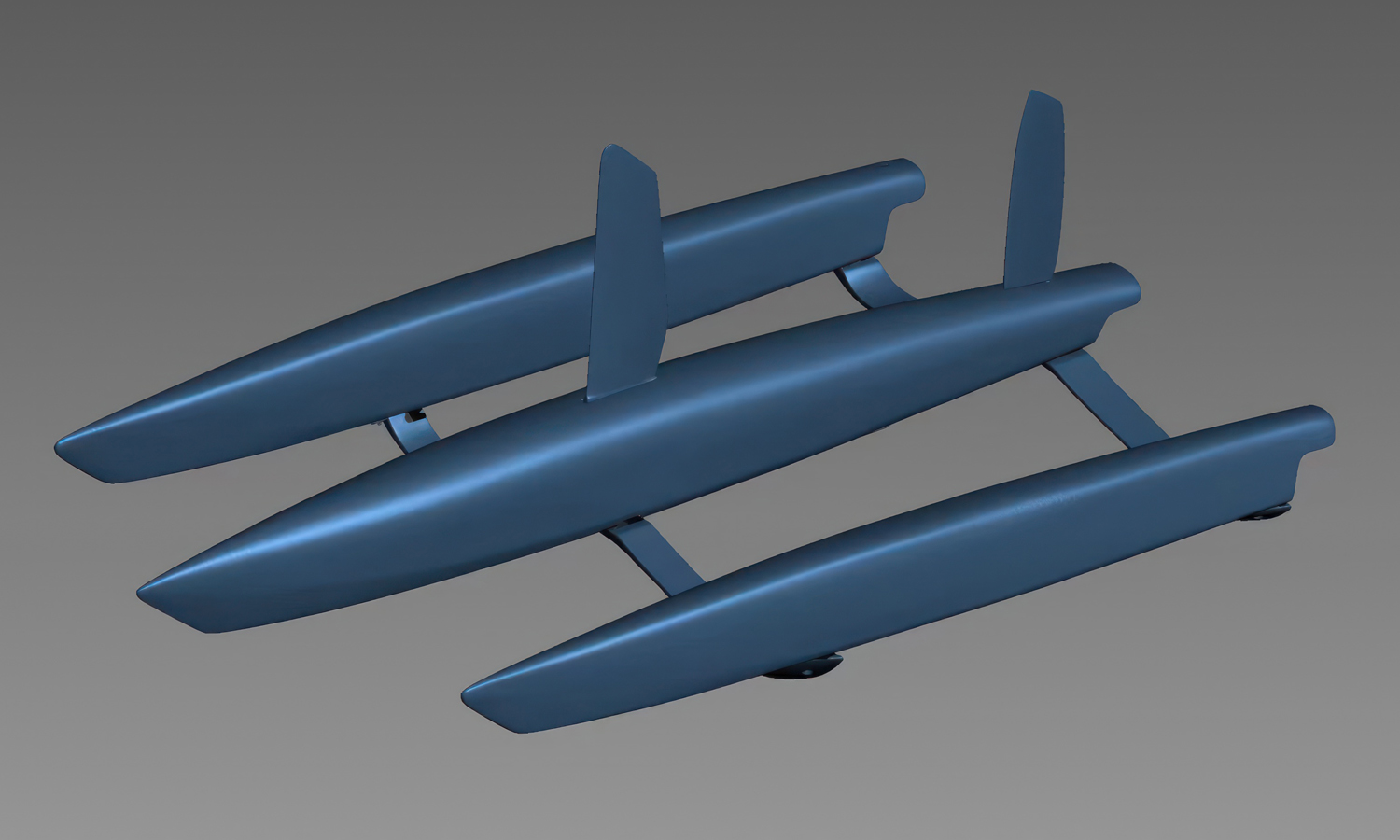

- Step 6: The mesh was converted into a watertight 3D model and aligned to standard coordinate planes to prepare for CAD reconstruction.

- Step 7: The mesh was reverse-engineered into solid CAD geometry through surface fitting, feature extraction, and dimensional referencing.

- Step 8: The final CAD model was validated by comparing it with the original scan data to ensure dimensional fidelity within engineering tolerances.