- Lost-wax Cast Silver Bracelets with Germany City Landscapes

- MJF 3D Printed Full-color Elder Woman Head Miniature

Gallery

About Project

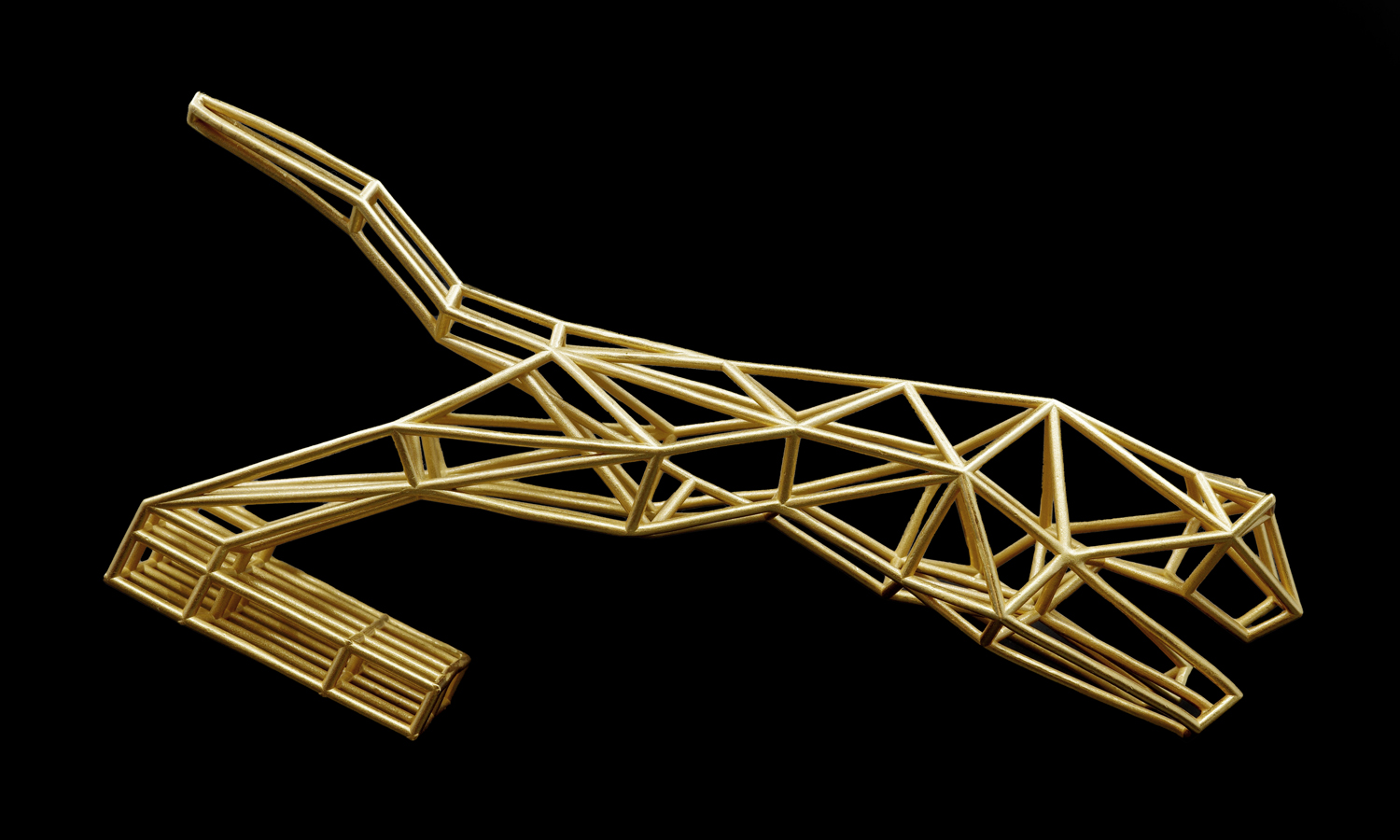

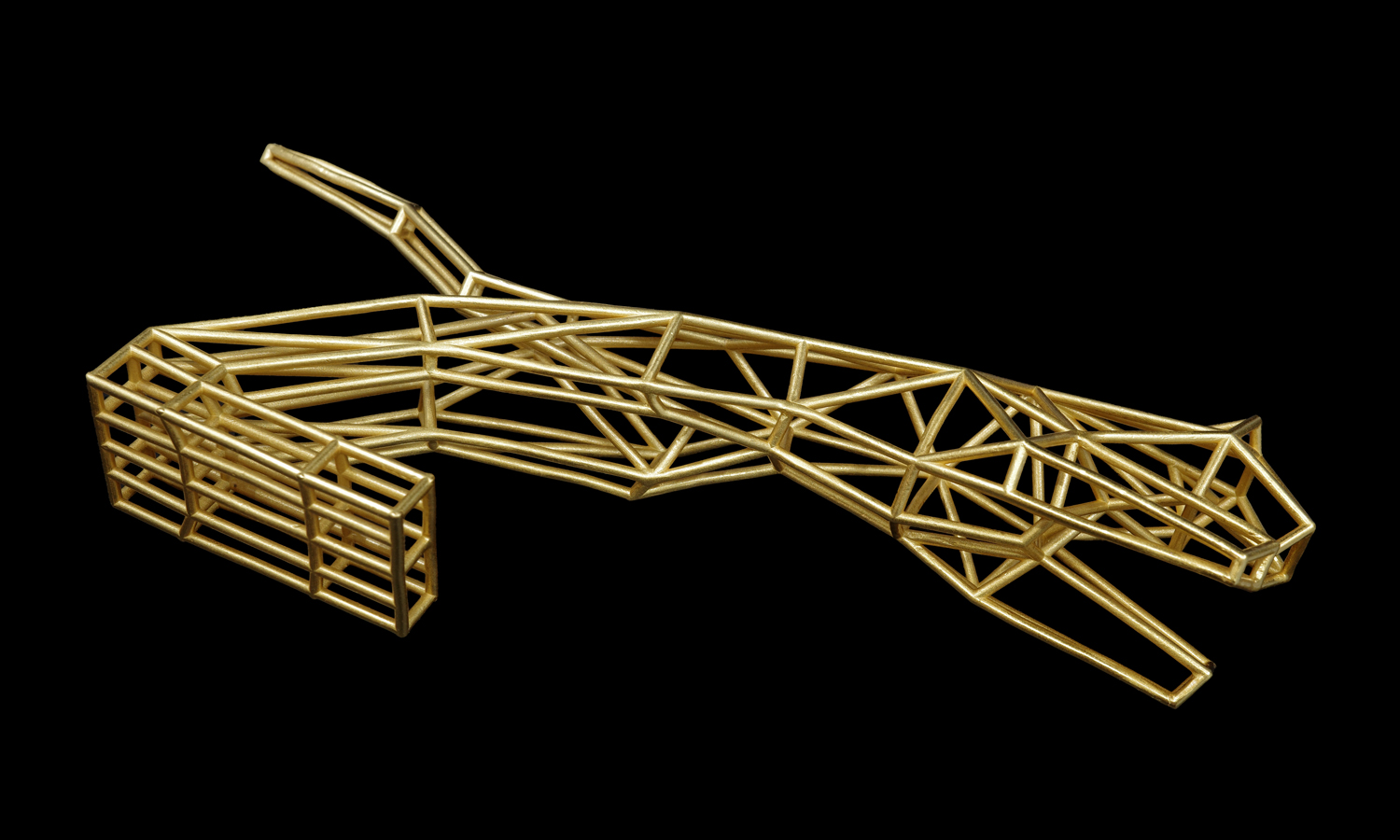

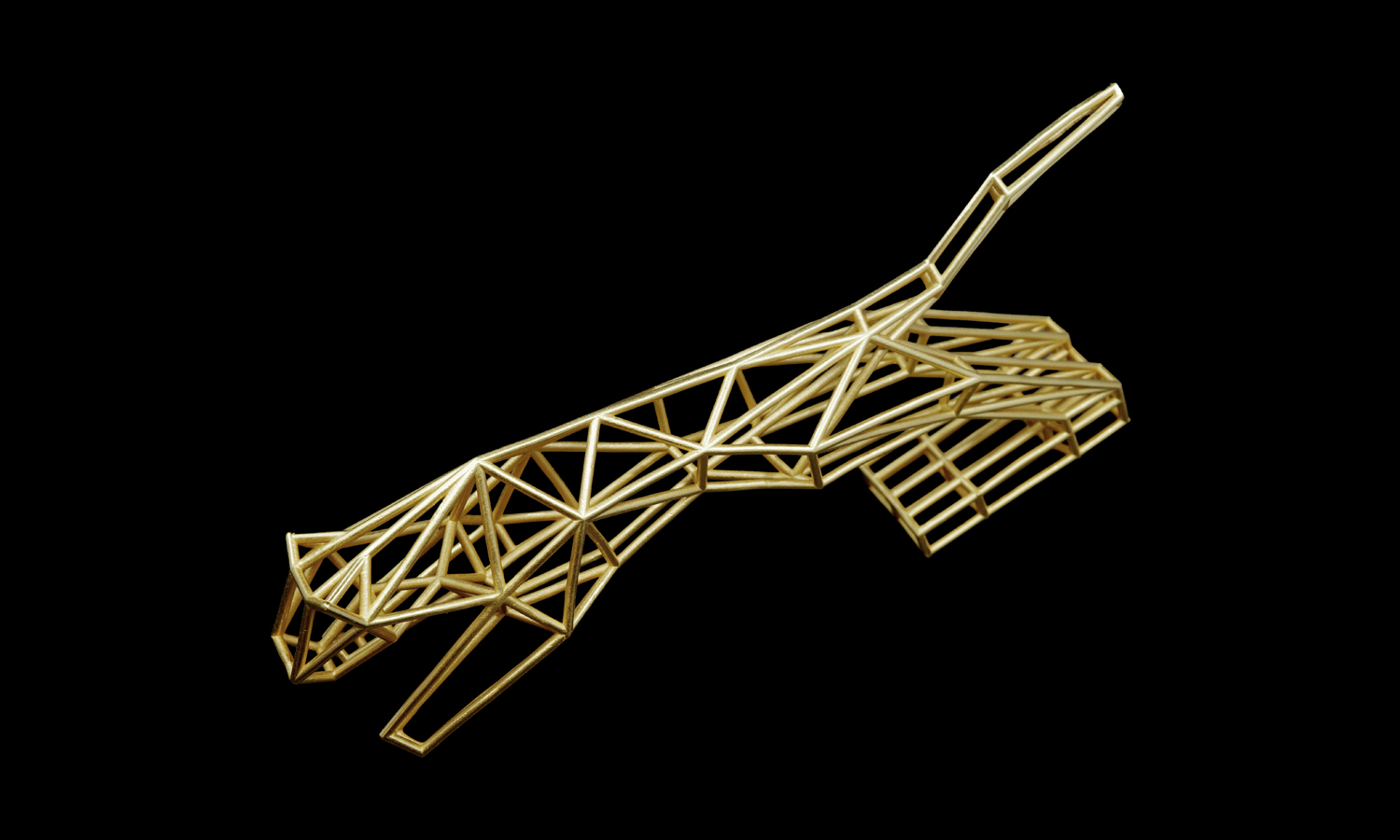

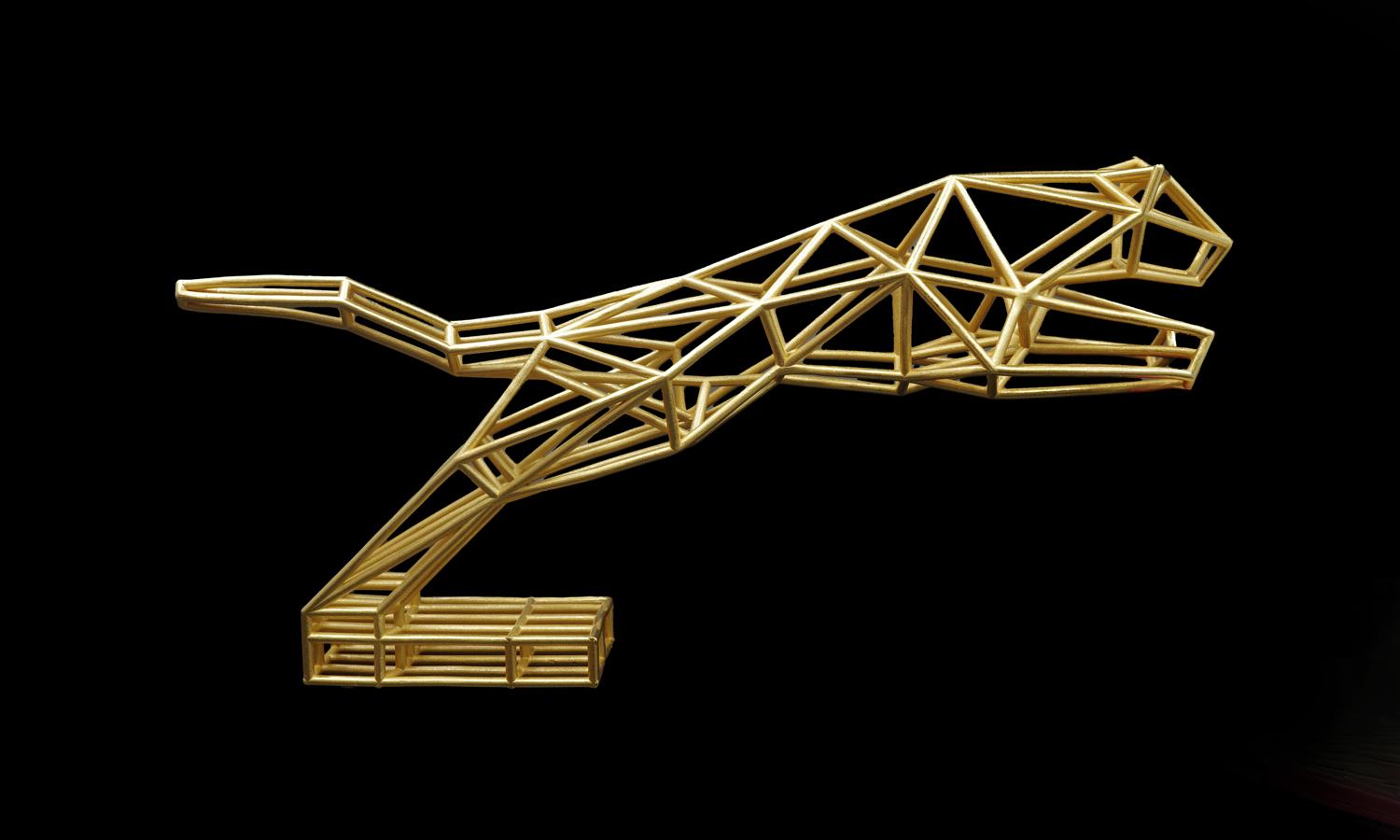

We are thrilled to showcase a masterpiece of modern manufacturing: the SLM 3D Printed Brass Cheetah Statue, a custom-designed film award prize for a prestigious Schweizer (Swiss) film award!

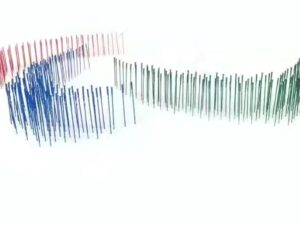

This isn’t just an award; it’s a testament to innovation and artistic vision. The statue depicts a powerful cheetah in a dynamic, leaping pose, crafted from an intricate, open lattice structure of interconnected brass geometric forms. Its skeletal yet robust design beautifully captures the essence of speed and grace, making it a truly unique and memorable symbol of cinematic achievement.

The cheetah is rendered in a captivating geometric style, formed by numerous slender, interconnected brass rods. It’s caught mid-stride, front legs extended, hind legs coiled, conveying immense power. The brass material gives it a sophisticated, metallic sheen, while the base is a solid block of densely packed rods, designed to be integrated (“buried”) within a larger display base, allowing the cheetah to appear as if emerging from its surroundings.

Why was 3D printing the ONLY solution for such an intricate structure?

Traditional manufacturing methods would struggle, if not fail entirely, to create this delicate yet strong network of brass. This is where Selective Laser Melting (SLM) 3D printing excels:

- Unparalleled Design Freedom: SLM allows for incredibly complex geometries, hollow structures, and intricate lattices impossible with conventional casting or machining. This enabled the designers to realize their vision of a geometrically deconstructed cheetah.

- Precision and Accuracy: Each slender rod and precise connection point is built layer by layer with exceptional accuracy, ensuring structural integrity and aesthetic appeal.

- Material Versatility: Printing directly with brass ensures a high-quality, durable, and lustrous finish, perfectly befitting a prestigious award.

- Customization on Demand: For bespoke awards like this, 3D printing offers ultimate flexibility. Each award can be tailored in design, size, and material without expensive tooling or lengthy production times.

Bring Your Vision to Life with FacFox Metal 3D Printing!

Inspired by the precision and artistry of this brass cheetah? Whether you’re designing custom awards, intricate prototypes, functional parts, or unique artistic creations, FacFox is your trusted partner for cutting-edge metal 3D printing services. We offer a wide range of materials, advanced printing technologies, and expert guidance to transform your most ambitious ideas into reality.

Contact FacFox today and discover the limitless possibilities of metal 3D printing for your next project!

Solution

- 3D Model Creation.┬ĀInitially, a detailed 3D digital model of the cheetah, incorporating its intricate lattice structure and designed base, was created using specialized CAD (Computer-Aided Design) software. This model served as the blueprint for the entire printing process.

- Slicing and Support Generation.┬ĀThe 3D model was then digitally sliced into hundreds or thousands of ultra-thin layers. Concurrently, temporary support structures were automatically generated within the software to prevent overhanging features from collapsing during printing.

- Printer Preparation.┬ĀThe SLM 3D printer was prepared. This involved filling the build chamber with a fine brass powder, which was evenly spread across the build platform by a recoater blade.

- Layer-by-Layer Melting.┬ĀThe printing process commenced. A high-powered laser beam was precisely directed onto the brass powder bed, following the contours of the first sliced layer of the cheetah model. The laser selectively melted and fused the brass particles, creating a solid cross-section.

- Platform Lowering and Repetition.┬ĀOnce a layer was completed, the build platform was incrementally lowered, and a new layer of brass powder was spread across the solidified surface. The laser then repeated the melting process for the subsequent layer, fusing it to the one below. This iterative process was continued until the entire brass cheetah statue, including its integrated base and support structures, was fully formed within the powder bed.

- Cooling.┬ĀAfter printing was completed, the build chamber was allowed to cool down to a safe temperature.

- Powder Removal.┬ĀThe excess, unfused brass powder surrounding the printed part was carefully removed, typically by vacuuming or brushing, and was then collected for recycling.

- Support Structure Removal.┬ĀThe temporary support structures, which were integral to the printing process, were meticulously removed from the brass statue. This was often done through manual breaking, cutting, or abrasive techniques.

- Post-Processing and Finishing. Finally, the brass cheetah statue underwent various post-processing steps. These often included surface finishing techniques such as sandblasting, polishing, or light grinding to achieve the desired aesthetic and smooth texture, ensuring the award’s pristine appearance.