- Micro 3D Printed Resin Models of Nanjing and Anqing Universities

- SLA 3D Printed Cable-stayed Suspension Bridge Resin Scaled-down Model

Material Metal

Quantity 6 pcs

Price Range $100-1,000

Lead Time 10 workdays

Gallery

About Project

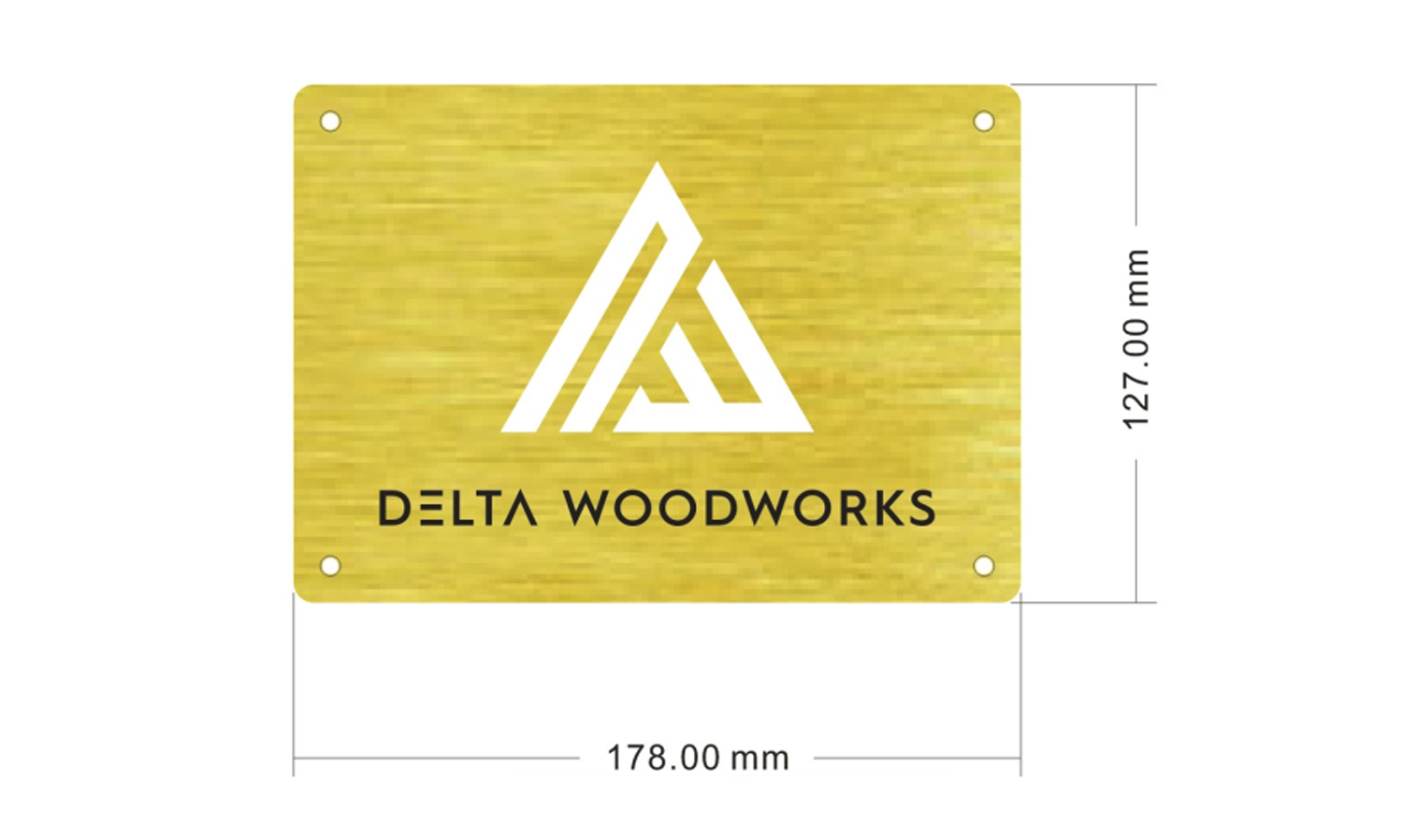

The wood workshop found us to make some plaques for their new showroom. The client sent a photo and ask if we could make something alike. We showed some cases we have completed before and asked for an AI file to calculate the quote. The amount is not sure but depending on the price. He has no requirements on the thickness so we advise a common 1mm thick.

Challenge

The client firstly wanted to make the plaques electroplated. Our engineer checked the size and informed him that electroplating such a 20*15cm big plaque would be difficult and led to surface defects. Then we raised the plan of cutting aluminum alloy or brass sheets with a brushed finish, and sent him the sample photo. He preferred the brass version.

And the client hoped to make the holes as countersinks, the diameter of the front and back of the holes are 5mm and 4mm. We used a CNC miller to process the countersinks.

Solution

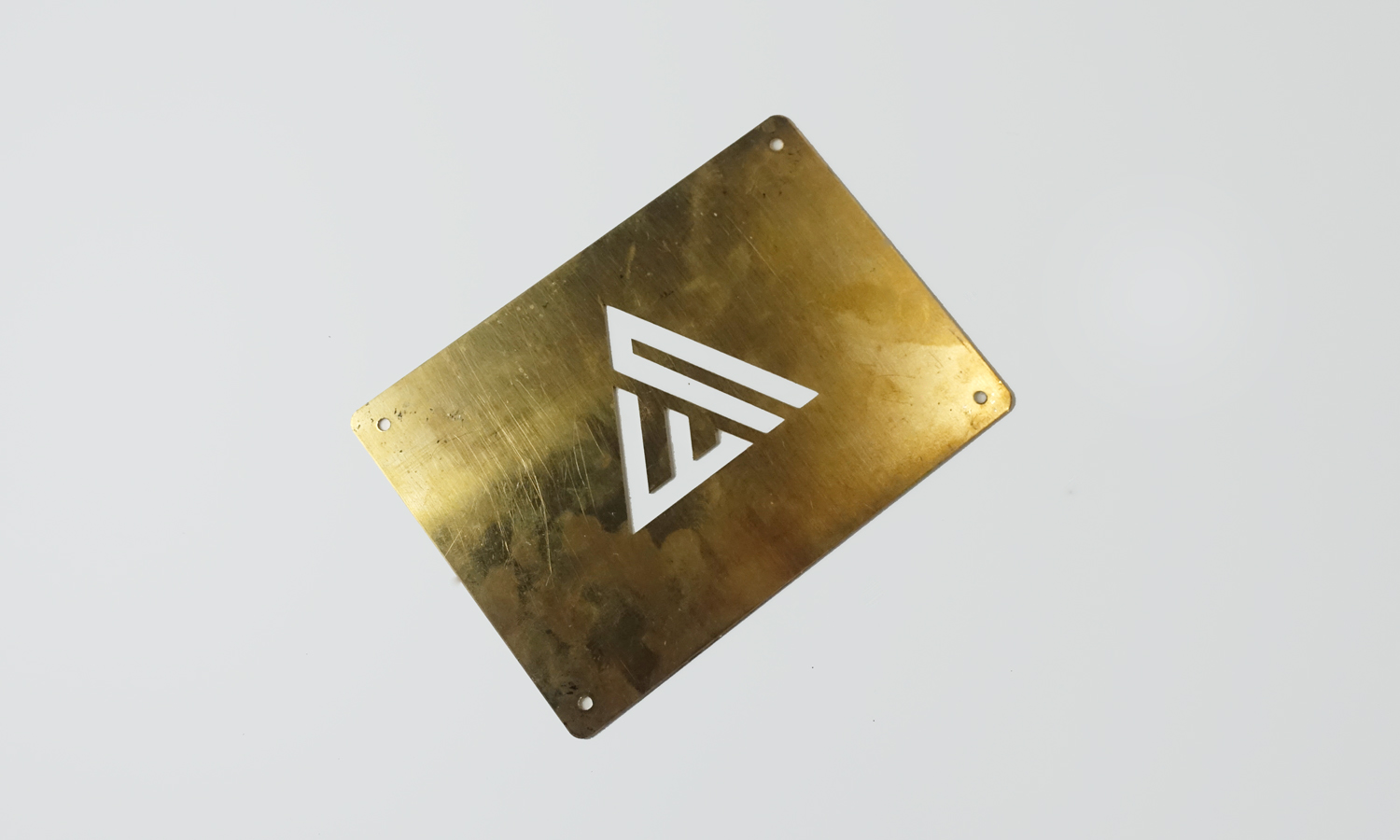

- Step 1: Give the quote based on the material, shapes and dimensions. Convert the AI file into .dwg, and import the file into the laser cutting machine.

- Step 2: Set the laser cutter, cut the brass sheets in the designed route. The cut marks show how the laser starts to cut the boards and have no impact on the shapes.

- Step 3: The metal is polished with a fine bristle brush on a belt or wheel that moves in the same direction the whole time, then softened with a greaseless compound or a medium non-woven abrasive belt or pad.

- Step 4: Cut the counterbores with a CNC miller. Then pack the finished plates. They are covered with a protective membrane on the front and the back would look dirty.