Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 3 workdays

Gallery

About Project

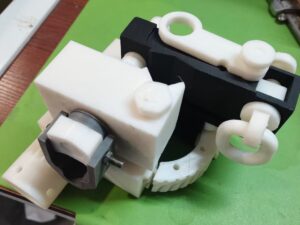

At first glance, they might look like simple hose connectors. But these particular components, crafted with SLA Formlabs High Temp Resin, tell a story of advanced engineering and problem-solving. These aren’t your average plastic parts; they’re designed for environments where standard materials simply can’t survive.

What Makes Them Special?

- Functionality:

These are “barbed hose adapters,” perfect for creating secure, leak-free connections between flexible tubing of

different diameters. The stepped ridges ensure a tight grip, ideal for fluid or air transfer systems. - Material Choice is Key:

The use of Formlabs High Temp Resin is the real differentiator. With a Heat Deflection Temperature (HDT) of 238┬░C @

0.45 MPa, these parts can withstand extreme heat. This makes them indispensable for applications in:- Automotive:

Prototyping under-the-hood components, fluid lines for engine testing. - Industrial:

Custom manifolds for hot liquids, steam systems, or high-temperature process equipment. - Medical/Lab:

Autoclavable jigs and fixtures that require sterilization at high temperatures.

- Automotive:

- Precision and Customization:

3D printing allows for intricate, custom geometries that might be difficult or costly to achieve with traditional

manufacturing methods. Need a specific barb size, a unique angle, or an integrated mounting feature? Additive

manufacturing makes it possible.

When off-the-shelf solutions don’t cut it, and you need parts that perform reliably under pressure and extreme

conditions, custom 3D printing with advanced engineering resins is the answer.

Ready to bring your high-performance designs to life?

FacFox offers expert 3D printing services, utilizing a wide range of advanced materials including high-temp resins, to

meet your most demanding application needs. From rapid prototyping to functional end-use parts, we provide precision,

speed, and quality.

Contact us today to discuss your project!

Solution

- Step 1: The 3D model was designed in CAD software and the file was exported into a printable STL format.

- Step 2: The digital file was processed using PreForm software, where the orientation was optimized and supports were

generated to ensure structural integrity during the build. - Step 3: The Formlabs High Temp resin was heated to a specific temperature within the printer to reduce viscosity before

the printing cycle began. - Step 4: The parts were fabricated layer-by-layer using a high-precision laser to UV-cure the liquid resin into a solid

form. - Step 5: The completed connectors were removed from the build platform and washed in Isopropyl Alcohol (IPA) to dissolve

any uncured material. - Step 6: The support structures were carefully removed, and the parts were placed in a UV-curing oven for a final post-cure

to achieve their maximum heat deflection properties. - Step 7: The barbed surfaces were inspected for dimensional accuracy and smoothed to ensure a leak-proof seal with flexible

tubing.