- 3D Printed Stormtrooper Helmet with SLA Castable Resin

- SLA 3D Printed Transparent Light Guide for Motorcycle Lighting Assembly

Material Metal

Quantity 60 pcs

Price Range $100-1,000

Lead Time 4 workdays

Gallery

About Project

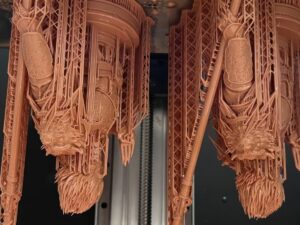

This project showcases a set of custom corporate gifts produced using Selective Laser Melting (SLM) 3D printing in aluminum alloy, combining industrial aesthetics with precise branding details. Designed as compact, functional keepsakes, the parts feature angular geometries, stepped contours, and integrated hanging loops-details that would be difficult or costly to achieve through conventional machining at small batch volumes.

SLM technology enabled the parts to be built layer by layer from aluminum alloy powder, resulting in dense, high-strength metal components with excellent structural integrity. The finished pieces present a refined metallic texture that highlights the additive manufacturing process itself, giving the gifts a distinctly modern and engineering-driven character-well aligned with the brand’s energy and technology positioning.

After printing and standard post-processing, the client added laser engraving to apply the company name and logo. Compared with printing the logo directly, laser marking delivered sharper edges, higher contrast, and long-term durability without affecting part strength or dimensional accuracy. The engraved branding sits cleanly on the angled surfaces, maintaining legibility while complementing the raw, premium feel of the aluminum.

These gifts demonstrate how metal 3D printing can move beyond prototyping into high-value brand applications. With design freedom, material performance, and flexible post-processing options, SLM allows companies to create memorable, fully customized items that reflect both technical capability and brand identity-even in low to medium quantities.

At FacFox, we support projects like this from concept to completion, offering SLM metal 3D printing, professional post-processing, and coordination with secondary processes such as laser engraving. Whether you’re developing functional parts or distinctive corporate gifts, FacFox helps turn complex metal designs into high-quality, production-ready results.

Solution

- Step 1: The 3D model was reviewed, and the hanging loop, stepped features, and engraving area were checked to ensure printability and sufficient wall thickness.

- Step 2: The part was oriented for SLM to balance surface quality, support accessibility, and dimensional stability, and then support structures were generated.

- Step 3: The aluminum alloy powder was prepared, and the SLM machine was set up with the required parameters for layer thickness, laser power, and scan strategy.

- Step 4: The parts were built layer by layer through Selective Laser Melting, and the build was completed under a controlled, inert atmosphere.

- Step 5: The build plate was cooled, and the printed parts were removed from the powder bed and depowdered to clear internal corners and fine details.

- Step 6: The parts were separated from the build plate, and the support structures were removed to achieve the intended outer profile.

- Step 7: Critical surfaces and edges were cleaned up, and minor burrs or marks from support removal were corrected.

- Step 8: The parts were bead blasted to create a uniform matte metallic finish and to visually even out the surface texture.

- Step 9: The laser engraving layout was aligned to the designated flat/angled face, and the company name and logo were laser marked with consistent contrast and sharp edges.

- Step 10: The finished parts were inspected for surface consistency, engraving clarity, and loop integrity, and then they were cleaned and packed as corporate gifts.