- SLA 3D Printed Transparent Light Guide for Motorcycle Lighting Assembly

- SLM 3D Printed Cobalt-Chrome Dental Components

Material Resin

Quantity 2 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

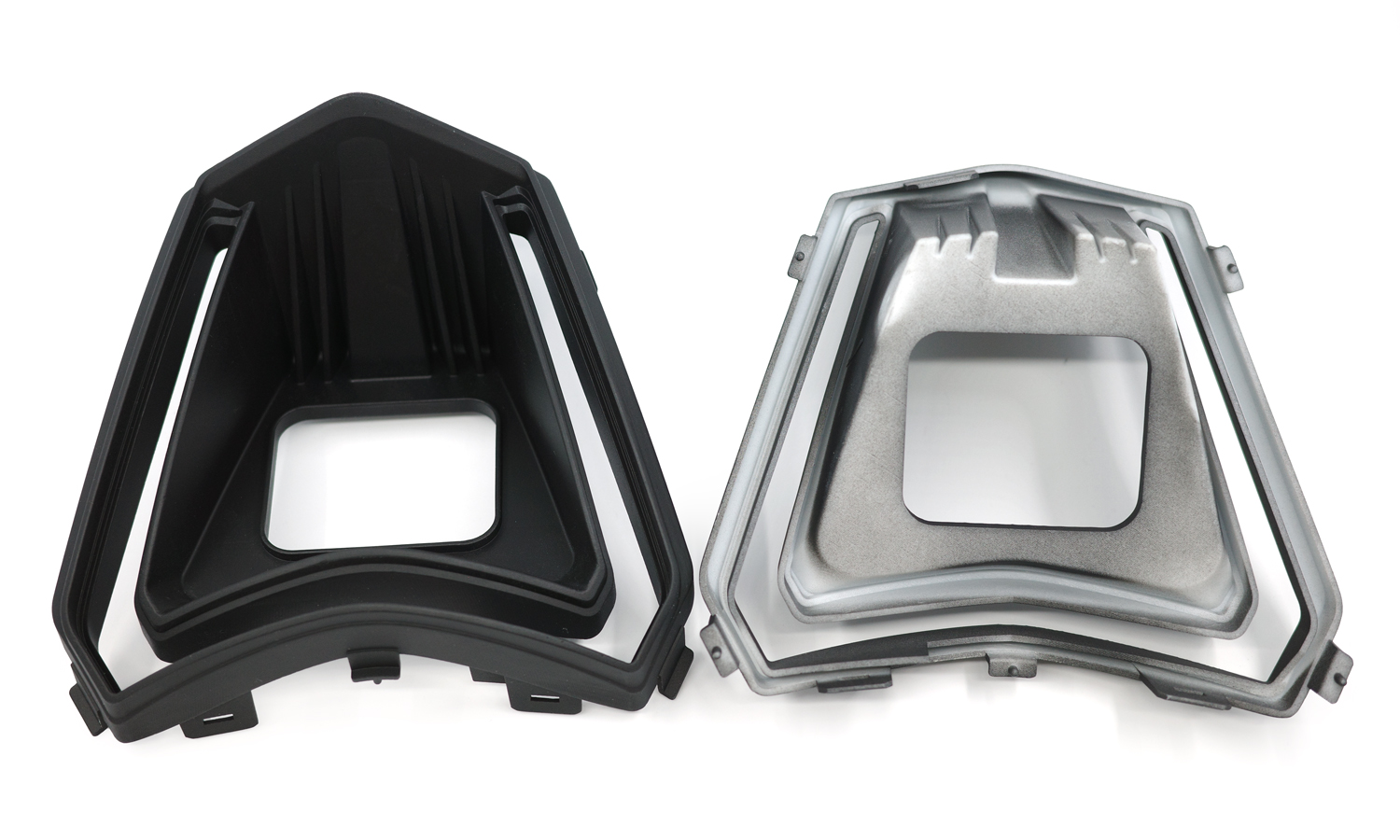

1. The “Hidden” Texture Difference

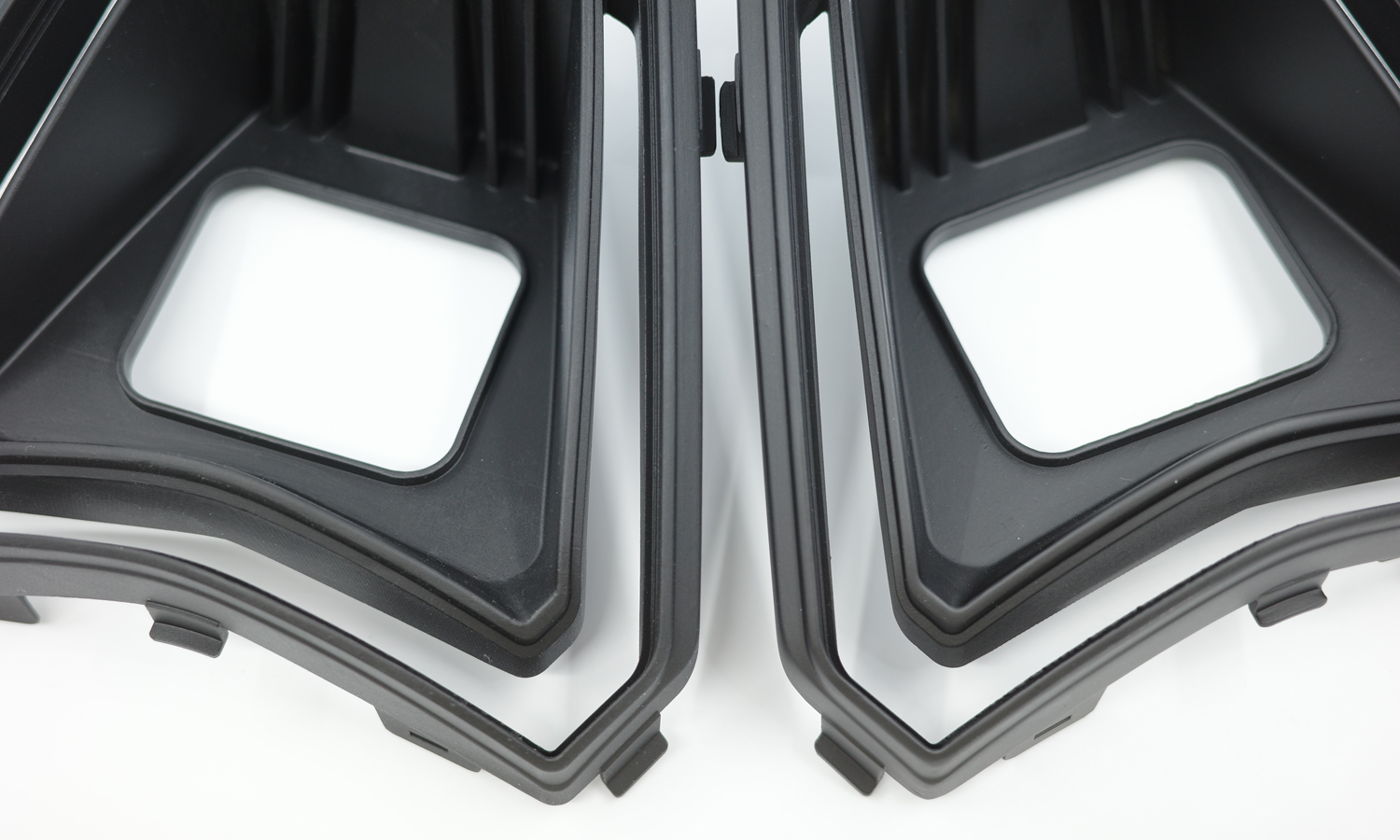

- Black Resin (Left): While the color is consistent, the surface is “raw.” If you look closely at the angled slopes, you can see subtle layer lines (aliasing). Because this part didn’t undergo heavy sanding or priming to preserve the solid material look, the 3D printing process remains visible.

- Painted Generic Resin (Right): This part has a much smoother, more “liquid” finish. This is because the painting process typically involves a primer filler or a base coat that settles into the micro-valleys of the layer lines. The paint acts as a leveling agent, masking the 3D printed nature of the part and giving it an injection-molded look.

2. The Trade-off: Aesthetics vs. Reality

- The Painted Advantage: By using generic resin and a professional paint job, you achieve a superior tactile smoothness. It feels more like a finished consumer product.

- The Black Resin Advantage: While you can see the layer lines under certain lighting, the part is mechanically “honest.” There is no paint to chip, and the dimensions are exactly what came off the printer.

Choosing the Right “Black”

In this comparison, we see a classic engineering dilemma. The Black Resin part is the “workhorse”-ideal for engine bays, mechanical assemblies, or high-touch areas where scratches are inevitable. The Painted Generic Resin part is the “showpiece”-the layer lines are gone, replaced by a smooth finish that is perfect for marketing samples, dashboard displays, or external housings where the “3D printed look” needs to be hidden.

Elevate Your Prototypes with FacFox

At FacFox, we understand that the right finish depends on your goal. If you need the ruggedness of pigmented resins, we offer high-resolution SLA printing that minimizes layer lines from the start. If you need a “Class-A” surface finish, our professional painting department uses high-build primers and premium automotive-grade paints to completely erase the 3D printing signature. From raw functional parts to showroom-ready models, FacFox provides the expertise to make your vision a reality.

Solution

Option A: Solid Black Resin (Flashforge DLP ABS-like Resin)

- Step 1: The 3D model was sliced and prepared for a High-Resolution DLP (Digital Light Processing) printer.

- Step 2: The part was printed using Flashforge DLP ABS-like Resin, a material pre-pigmented with black carbon and designed for high impact resistance.

- Step 3: The completed part was removed from the build plate and washed in high-purity Isopropyl Alcohol (IPA) to remove uncured resin.

- Step 4: Support structures were carefully removed using precision snips, leaving minor witness marks on the attachment points.

- Step 5: The part was placed in a UV curing chamber where it was subjected to specific wavelengths to reach its final mechanical strength.

- Step 6: A light manual buffing was performed on the support areas, while the rest of the part was left in its raw, “honest” state to maintain the solid black material integrity.

Option B: Painted Generic Resin

- Step 1: The component was printed using Generic Resin on an SLA/DLP system, resulting in a translucent or light-grey base part.

- Step 2: After the standard cleaning and UV-curing cycles, the part was subjected to extensive manual sanding to reduce the visibility of layer lines.

- Step 3: A layer of high-build primer was applied to the surface; this acted as a filler to settle into the microscopic valleys of the 3D printed layers.

- Step 4: Once the primer was dried, the part was lightly sanded again to ensure a perfectly leveled, “liquid-smooth” substrate.

- Step 5: A professional matte black topcoat was spray-applied to the exterior surfaces, creating the final high-end aesthetic.

- Step 6: The part was air-dried in a dust-free environment, resulting in a finish where the 3D printed origins were almost entirely masked.