- Transparent Helical Coupler Prototype Cast in PU Resin

- Industrial Housings 3D Printed with Nylon Glass Fiber

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

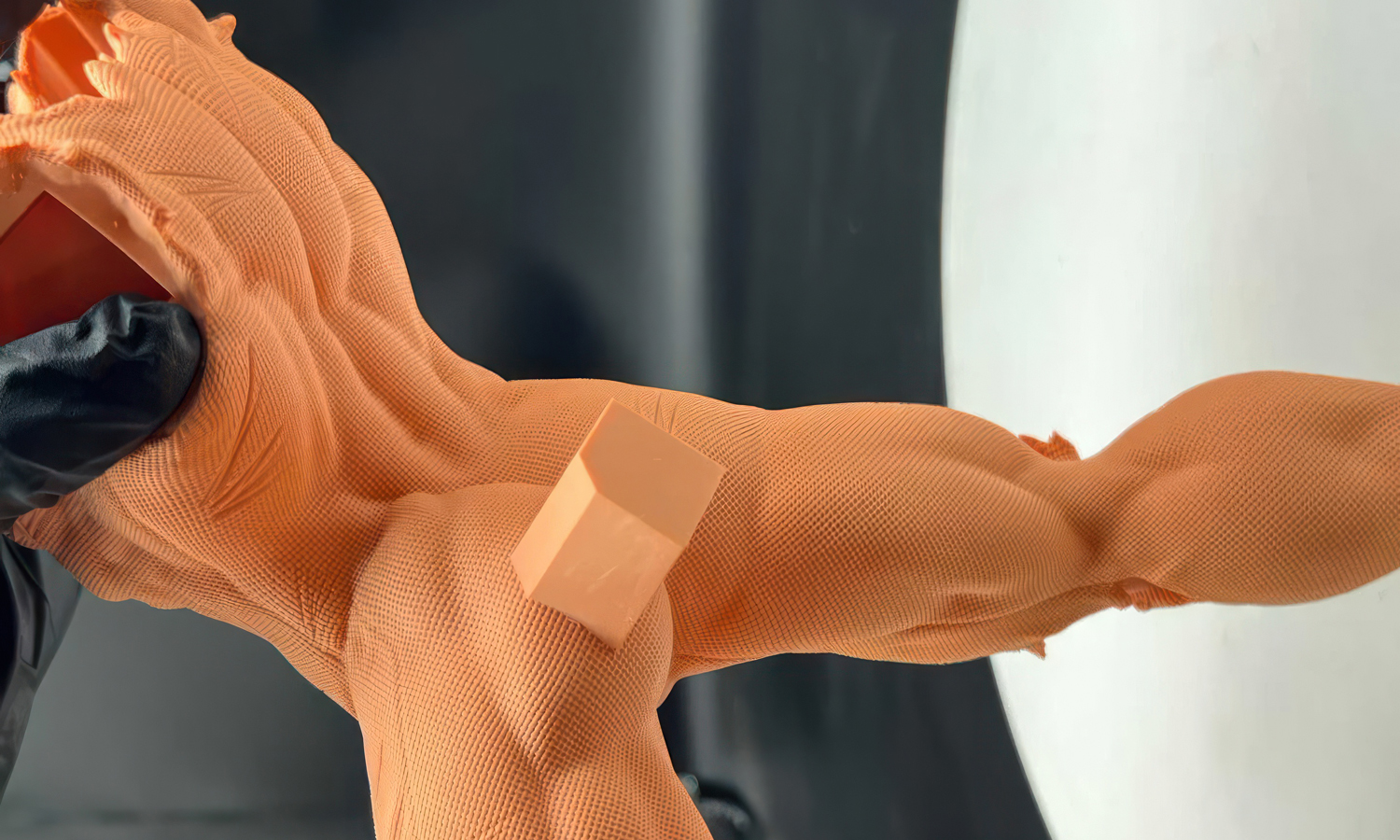

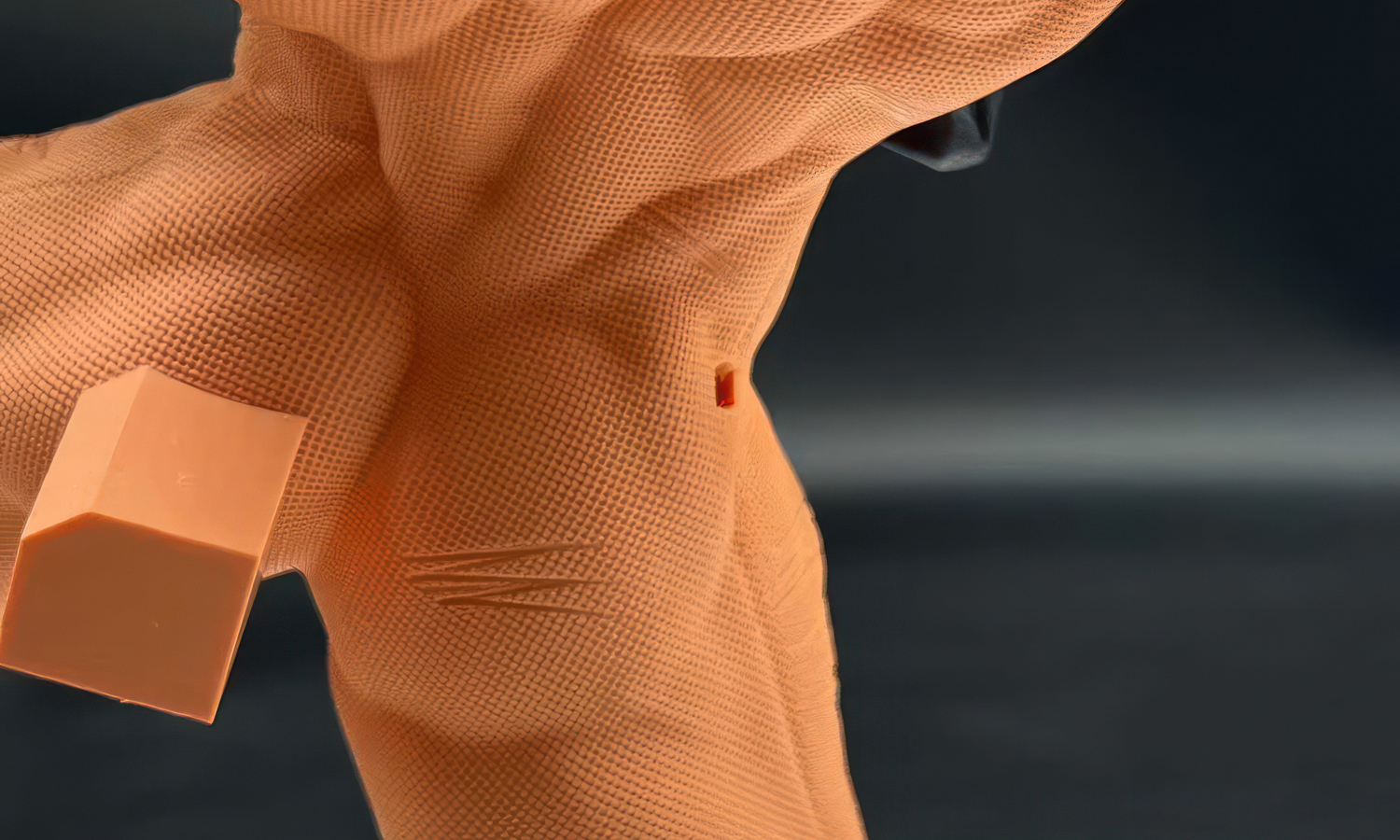

This large-scale anime figure component – featuring the muscular torso and legs of a battle-ready character – was printed as one part of a complex multi-piece statue. The final assembly will include multiple interlocking sections designed for precision fitting and detailed painting.

Standing around 25 cm tall, the piece showcases high-resolution sculptural detailing: well-defined muscles, textured clothing, and realistic tearing effects. It also includes several solid connector blocks, ensuring tight alignment with adjoining parts during final assembly.

Material & Technology

- Printing Technology: DLP (Digital Light Processing)

- Material: DLP Ultra Detail Resin

- Layer Thickness: 0.05 mm

- Part Height: ~250 mm

DLP Ultra Detail Resin is engineered for exceptional surface precision, offering sharp detail reproduction and minimal layer stepping even on large models. The material’s low shrinkage and high stability make it ideal for multipart figure prototypes where dimensional accuracy is critical.

Conclusion

This print highlights the power of FacFox’s DLP Ultra Detail Resin 3D printing for professional collectible production. With near-polish-free surfaces, ultra-high resolution, and accurate fitting between segmented parts, it’s an ideal choice for anime figures, prototypes, and finely detailed sculptures.

At FacFox, we combine advanced DLP technology with expert file preparation and finishing techniques to deliver stunning prototypes that bring creators’ visions to life.

¤æē Learn more about DLP Ultra Detail Resin here: https://facfox.com/materials/dlp-ultra-detail-resin/.

Solution

- Step 1: Model Preparation. The client’s digital sculpt was separated into multiple printable sections. Connector blocks and sockets were modeled at key joints for accurate alignment and easy assembly.

- Step 2: Support Placement & Slicing. Supports were automatically generated in the slicer, with additional manual adjustments to protect fine clothing details and muscular contours.

- Step 3: DLP Printing. The part was printed with ultra-thin layers, projecting each cross-section of the model using a digital light source for maximum precision and speed. The resin cured cleanly, preserving the model’s sculpted micro-textures.

- Step 4: Post-Processing. After printing, supports were carefully removed, and the model was cleaned in isopropyl alcohol and fully UV-cured.Unlike SLA or FDM prints, DLP prints from Ultra Detail Resin require nearly no polishing – the surface is already smooth and consistent straight out of the curing chamber. Only minor trimming was needed at the connection points.

- Step 5: Quality Inspection & Assembly Fit Test. The piece was dry-fitted with its neighboring sections. The connector blocks aligned perfectly, confirming excellent dimensional accuracy and inter-part compatibility.