- CNC Transparent Car Model Showcases Engineering Brilliance

- FDM 3D Printed Grid-Pattern Crossbody Bag

Gallery

About Project

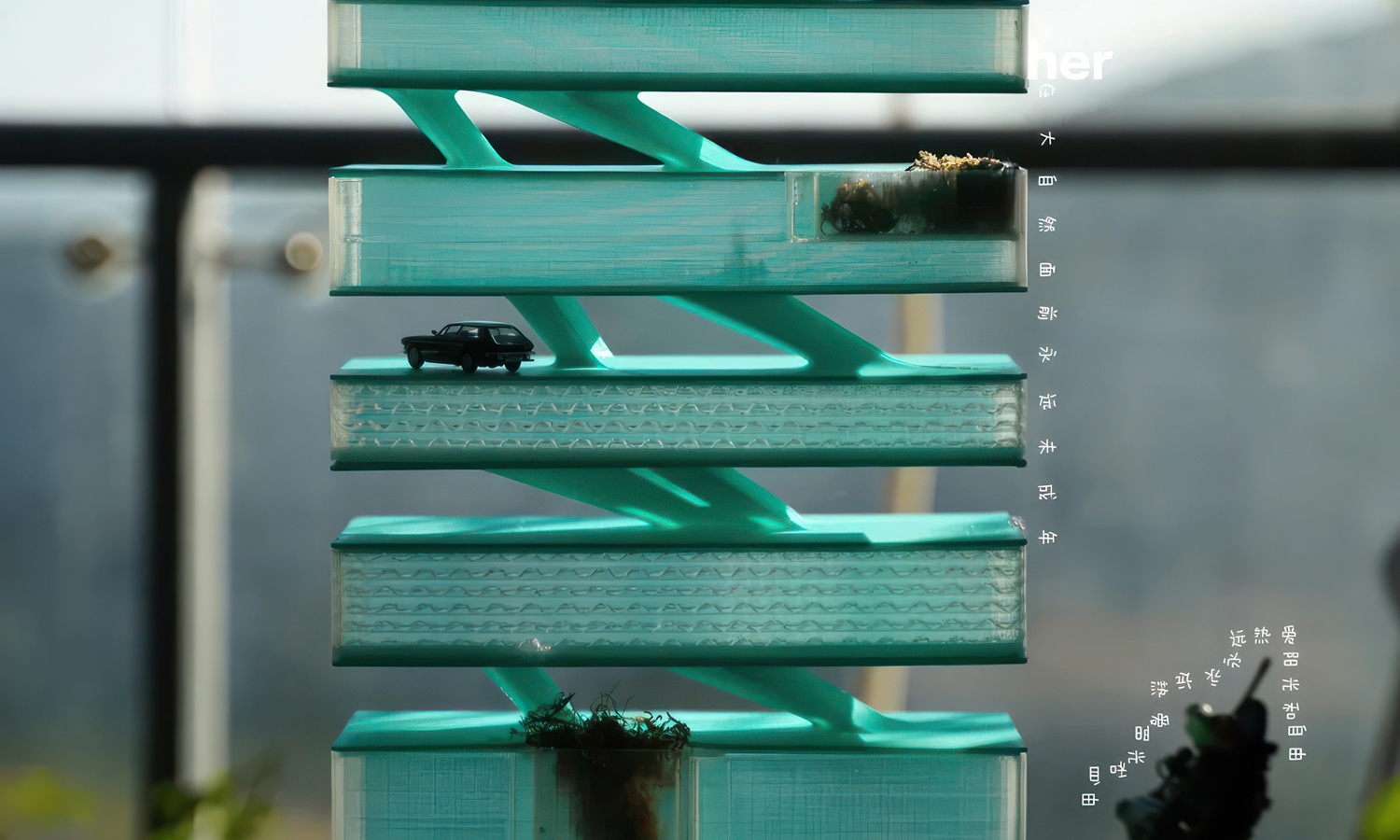

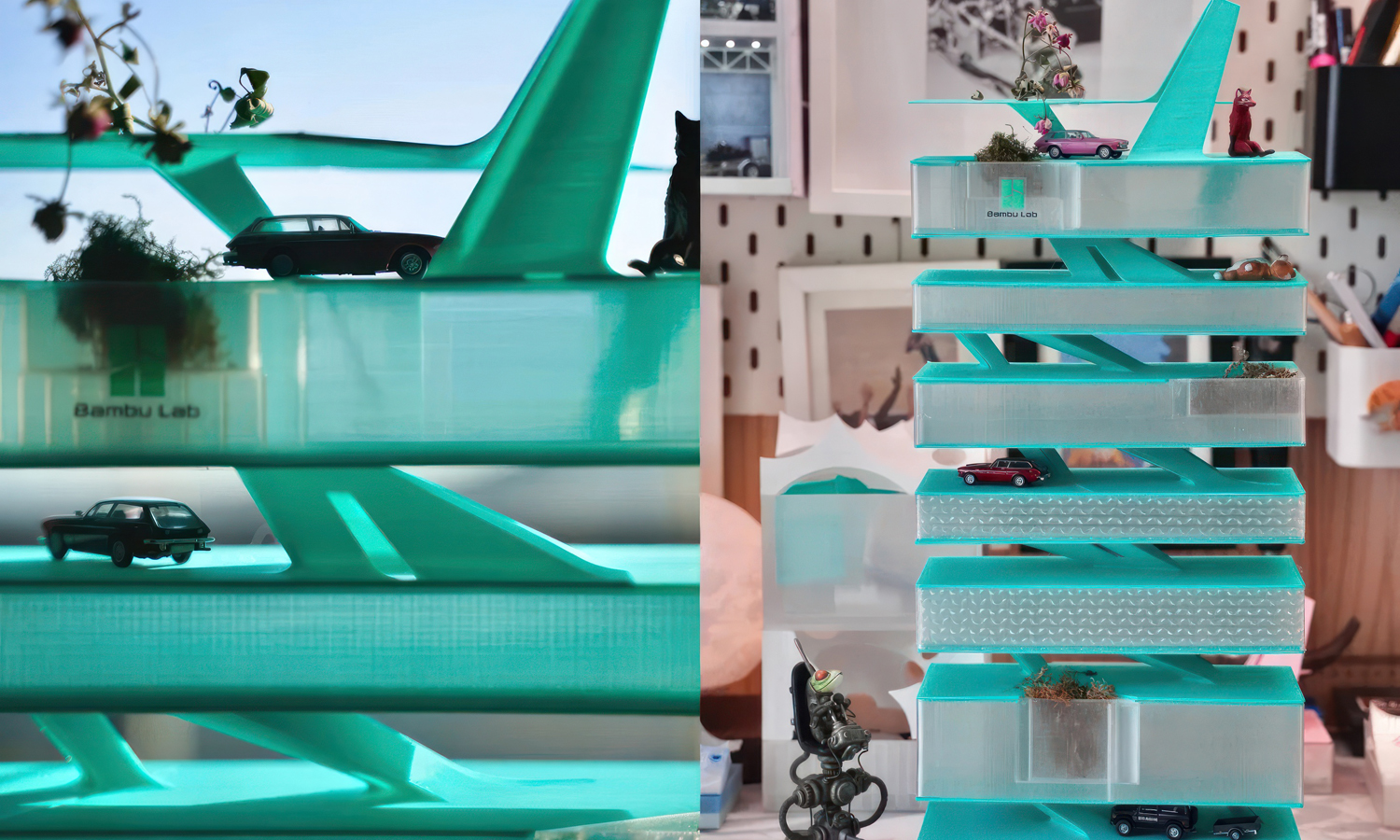

This striking architectural model reimagines the traditional parking structure as a piece of sculptural urban art. Designed with a zigzagging central ramp, offset floor plates, and open fa├¦ades, it embodies the dynamism of movement and layered city life.

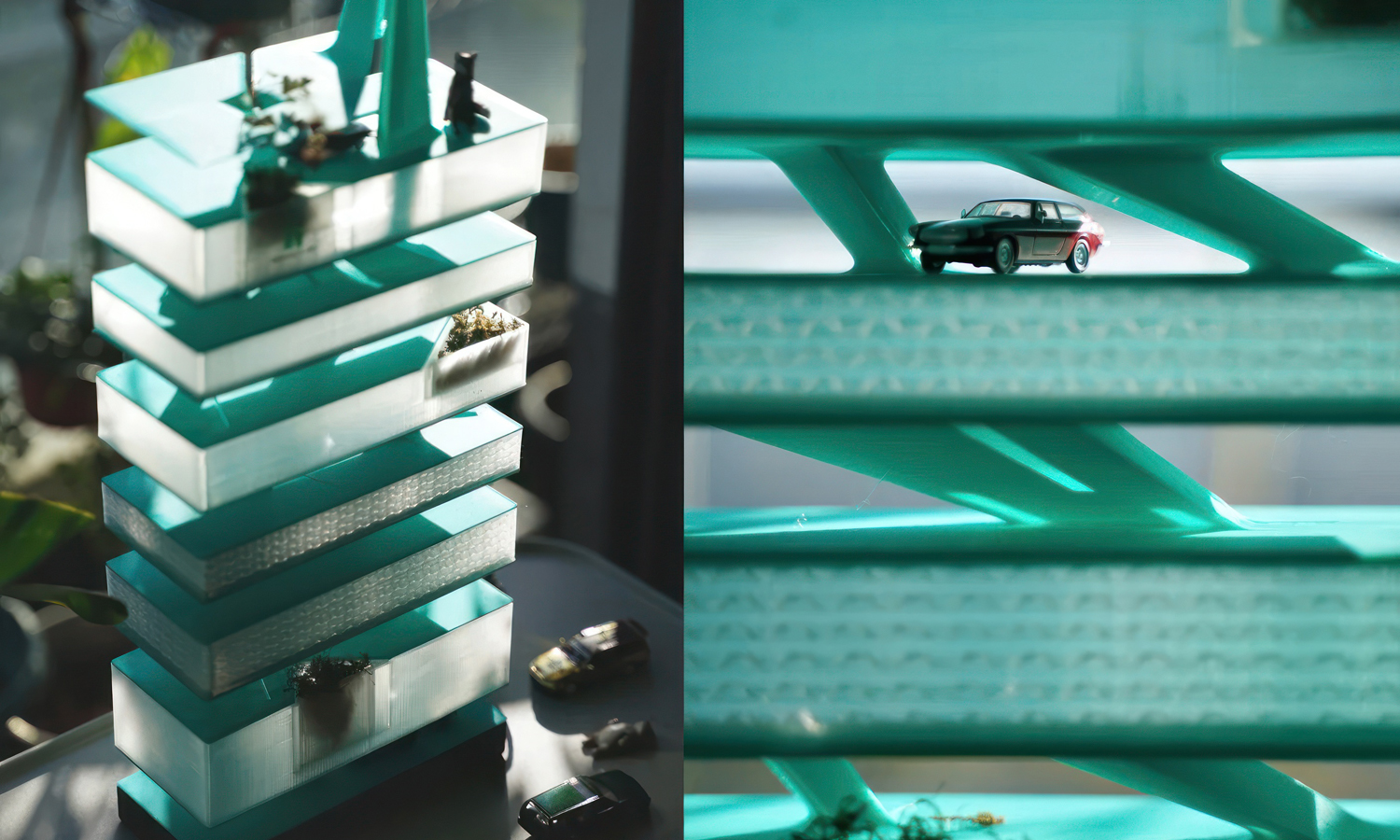

Each translucent floor plate houses miniature details – cars, figurines, and greenery – creating the feel of a microcosm where transportation, leisure, and nature coexist. The translucent turquoise filament allows natural light to filter through, giving the model a vibrant, futuristic glow, while the solid black base, emblazoned with Corbusier Guo┬«, grounds the design in both stability and personality.

The entire structure was 3D printed from a single filament type, ensuring seamless color consistency across all levels, while the base was printed solid to provide robust support. High-resolution FDM printing captures the fine ramp geometry, delicate facade patterns, and crisp architectural lines without the need for multi-material switching.

Why 3D Printing Works for Conceptual Architecture

3D printing allows architects and designers to quickly translate visionary concepts into tangible models. From experimenting with structural forms to exploring light interactions through translucent materials, the process offers unmatched flexibility and speed. Complex internal geometries like the zigzagging ramps can be printed in one go – no assembly required.

At FacFox, we specialize in turning bold architectural ideas into precise, high-quality models. Whether you need a conceptual parking tower, an urban masterplan mock-up, or an interior design prototype, our advanced FDM, SLA, and SLS, PolyJet, and other services bring your visions to life.

Solution

- Step 1:The 3D model of the conceptual parking structure was designed in CAD software, incorporating offset floor plates, a zigzagging central ramp, and detailed facade patterns.

- Step 2: The design was prepared for FDM 3D printing, with all main structural parts assigned to a single translucent turquoise filament for visual consistency, and the base assigned to solid black filament for stability.

- Step 3: The model was sliced with high-resolution settings to ensure smooth surfaces, precise ramp geometry, and accurate facade detailing.

- Step 4: The structure was printed in a single continuous process, with the translucent filament forming all upper floors and ramp connections, while the base was printed separately in solid black filament.

- Step 5: After printing, support structures were carefully removed to preserve fine edges and architectural details.

- Step 6: The printed parts were cleaned and lightly sanded to remove any minor surface imperfections, enhancing the clarity of the translucent sections.

- Step 7: Miniature model cars, figurines, and greenery were placed on each floor to bring the concept to life and demonstrate scale and potential usage.