- FDM 3D Printed PETG Shell Replacement for Logitech Master 3

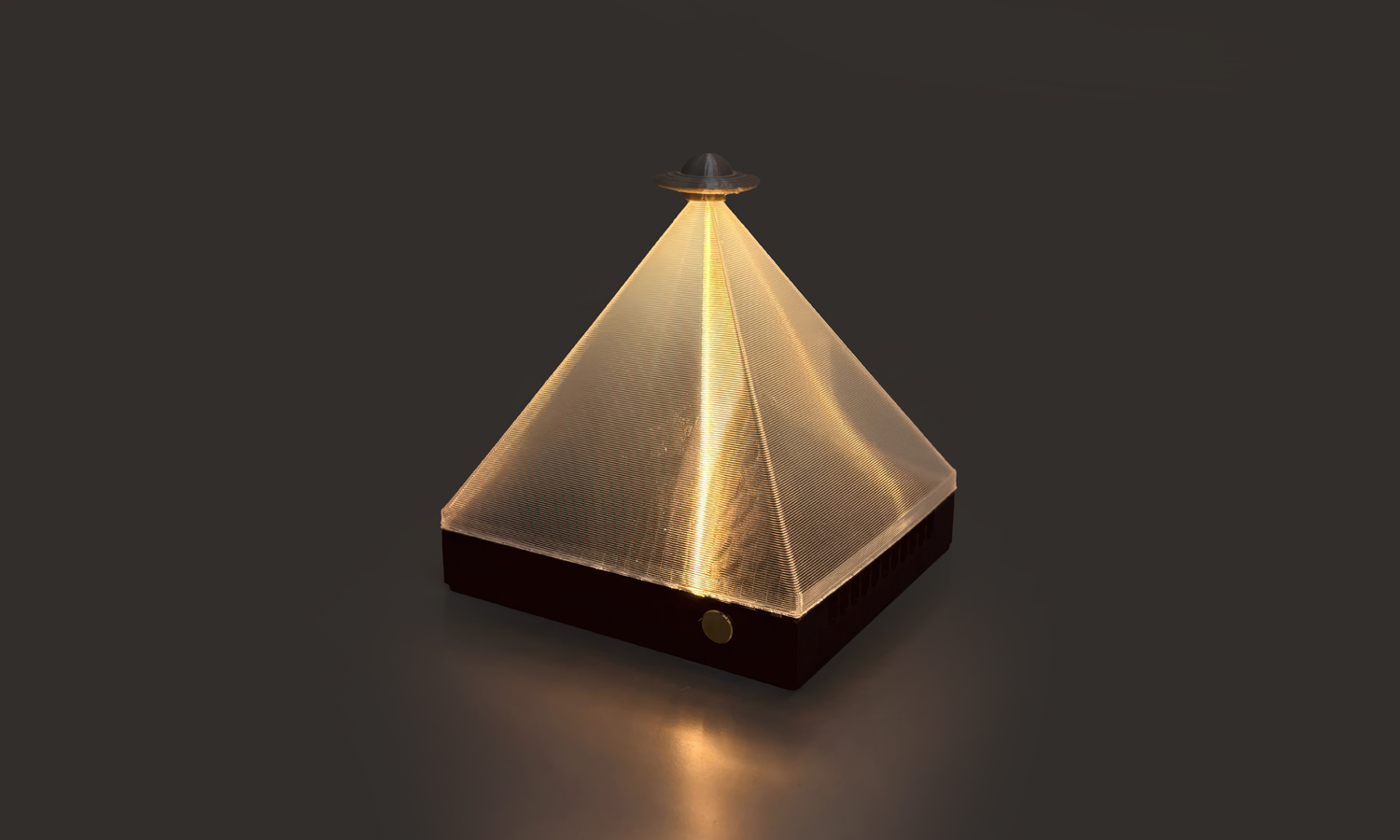

- SLA 3D Printed Mirror-Polished Resin Abstract Sculpture

Material Plastic

Quantity 80 pcs

Price Range $100-1,000

Lead Time 4 workdays

Gallery

About Project

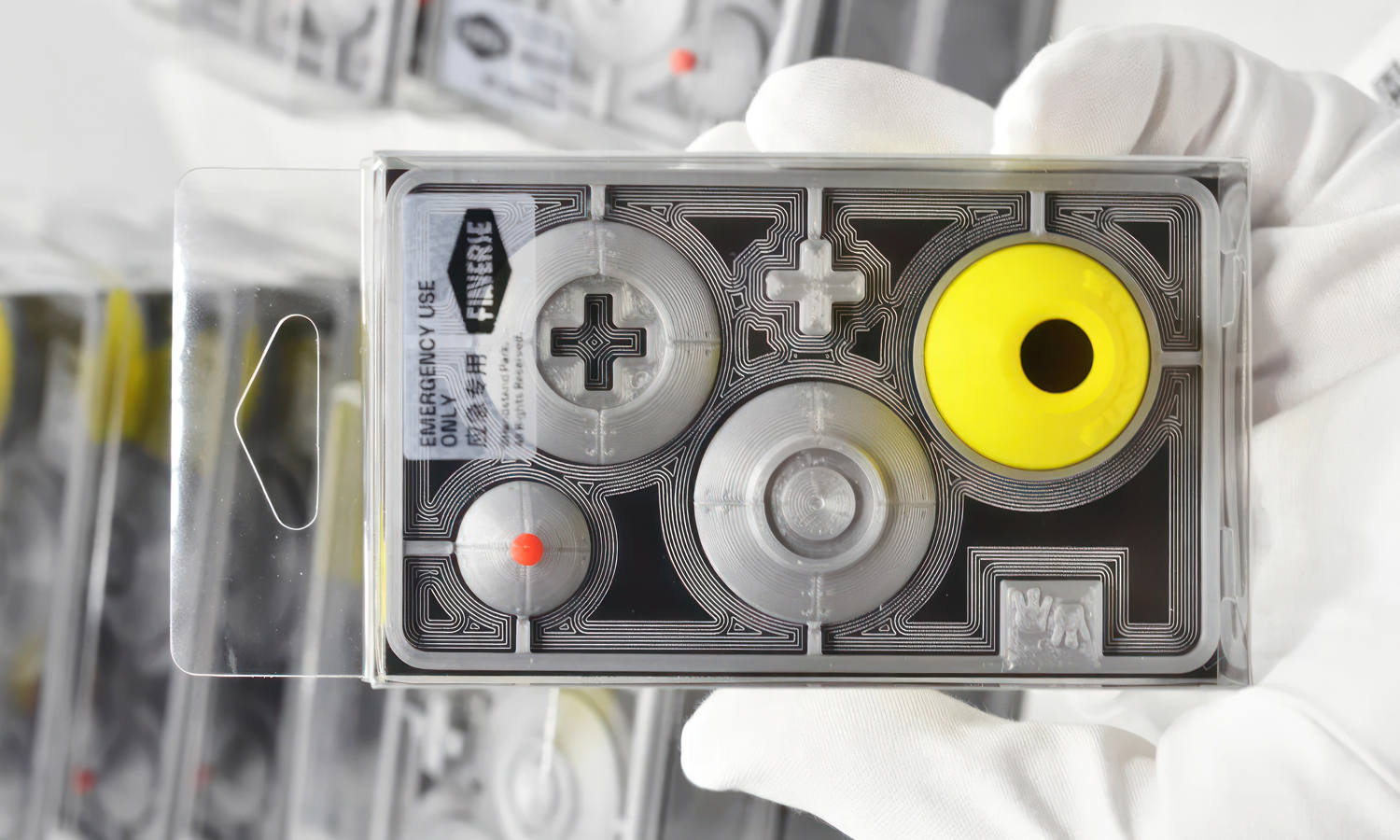

Designed & produced by @handstand_park, this quirky little spacecraft comes in a sleek, compact package that fits right in your bag. Wherever you are, just pop it open, snap the parts together, and boom-you’ve just assembled your own flying saucer, ready to abduct boredom and beam in the fun.

Each set features beautifully FDM 3D printed parts in bold colors, stacked neatly in a collectible-style kit. It’s part toy, part art, and 100% conversation starter. Whether you’re into DIY miniatures, sci-fi vibes, or unique desk companions, this UFO is ready for liftoff.

Invasion has never been this adorable.

Got a wild idea like this?

At FacFox, we help turn bold ideas into reality with professional 3D printing services. From art toys to creative gadgets, 3D printing is perfect for small-batch production – no molds, no minimums, just your imagination brought to life. You’ve got the idea, we’ve got the tools – you make the fortune.

Explore your next project with us ¤æē [facfox.com]

Solution

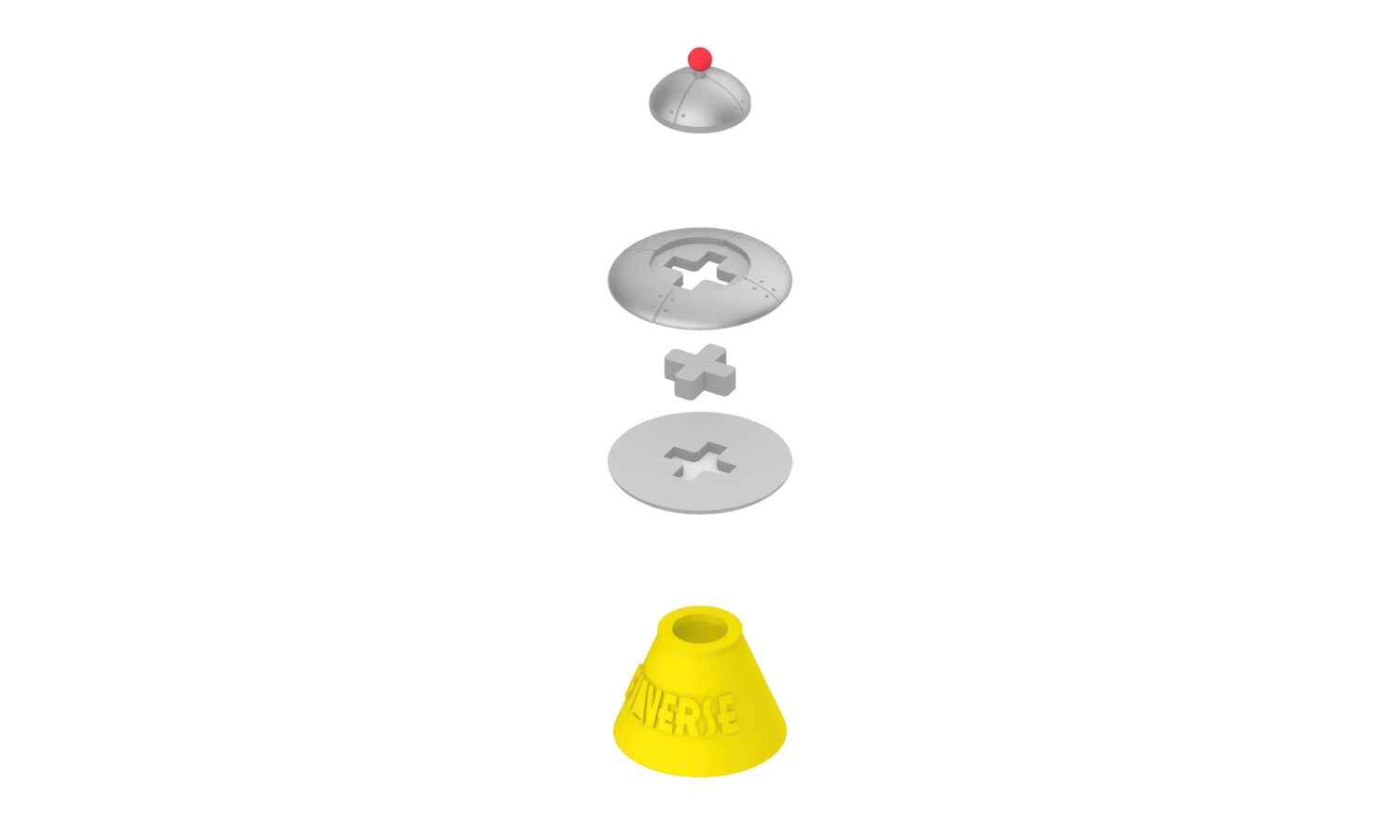

- Step 1: Design Phase. The UFO model was digitally designed by @handstand_park using 3D modeling software. Separate components-including the dome, saucer, beam cone, and antenna-were modeled individually for optimized print orientation and assembly.

- Step 2: File Preparation. The STL files were sliced using FDM-compatible software. Layer height, support structures, and color-coded filament assignments were configured according to the desired finish.

- Step 3: 3D Printing. Each part was printed using FDM (Fused Deposition Modeling) technology. PLA filament in silver, yellow, and red was selected for vibrant contrast and durability. Multiple sets were produced simultaneously for efficiency.

- Step 4: Post-Processing. After printing, support structures were carefully removed. Minor imperfections were smoothed by hand where necessary. All parts were inspected for dimensional accuracy and surface quality.

- Step 5: Assembly & Quality Control. The components were manually fitted and test-assembled to ensure seamless snap-fit function. The red antenna tip was press-fit onto the dome cap as the final detail.

- Step 6: Packaging. Each UFO kit was arranged in a blister tray, with parts slotted securely. The tray was inserted into a custom clear plastic shell to allow full visibility while keeping the kit compact and portable.

- Step 7: Distribution. Finished units were stacked, boxed, and prepared for retail or direct distribution. The compact format allowed easy transport and on-the-go assembly.