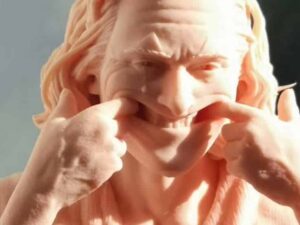

- ColorJet 3D Printed Full-color Elder Man Head Miniature

- ColorJet 3D Printed Full-color Henry Fox Miniature

Gallery

About Project

Just got my hands on a set of full-color swatches produced with ColorJet 3D printing on resin, and it’s quite the experience to see the possibilities firsthand! The most immediate impression is the strong color contrast. The darker hues definitely lean towards a deep, almost shadowy tone, while the lighter shades appear quite bright. This creates a noticeable vibrancy and pop in the overall color palette. The saturation is also impressively high, making the colors feel rich and intense.

However, looking closer reveals some of the technology’s current limitations. The edges of the color blocks aren’t as crisp as I might have hoped, exhibiting a noticeable softness or blurring. Examining the surface texture, it’s clear that it’s less uniform compared to something like MJF Nylon. There are visible undulations and a slight roughness, which in turn cause noticeable reflections where the surface isn’t perfectly flat.

Despite these imperfections, the ability to produce full-color parts directly is undeniably powerful for prototyping, visualization, and even artistic applications. The vividness of the colors and the strong contrast offer a unique aesthetic that can be highly impactful.

Want to bring your colorful ideas to life? FacFox offers professional ColorJet 3D printing services, leveraging their expertise to help you create stunning full-color prototypes and end-use parts. Explore the possibilities and get a quote for your next project today!

Solution

- Step 1: A digital 3D model was created and then sliced into thin cross-sectional layers.

- Step 2: A thin layer of powder-based resin material was spread across the build platform.

- Step 3: Inkjet print heads were used to selectively deposit both colored ink and a binding agent onto the powder layer, solidifying the material in the desired areas and colors.

- Step 4: For each subsequent layer, a new layer of powder was spread, and the process of ink and binder deposition was repeated, with each layer adhering to the previous one.

- Step 5: Once the printing process was complete, the unbound powder was carefully removed, revealing the full-color 3D printed parts.

- Step 6: Post-processing, such as cleaning and potentially sealing, was performed to enhance the final appearance and durability of the swatches.