Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

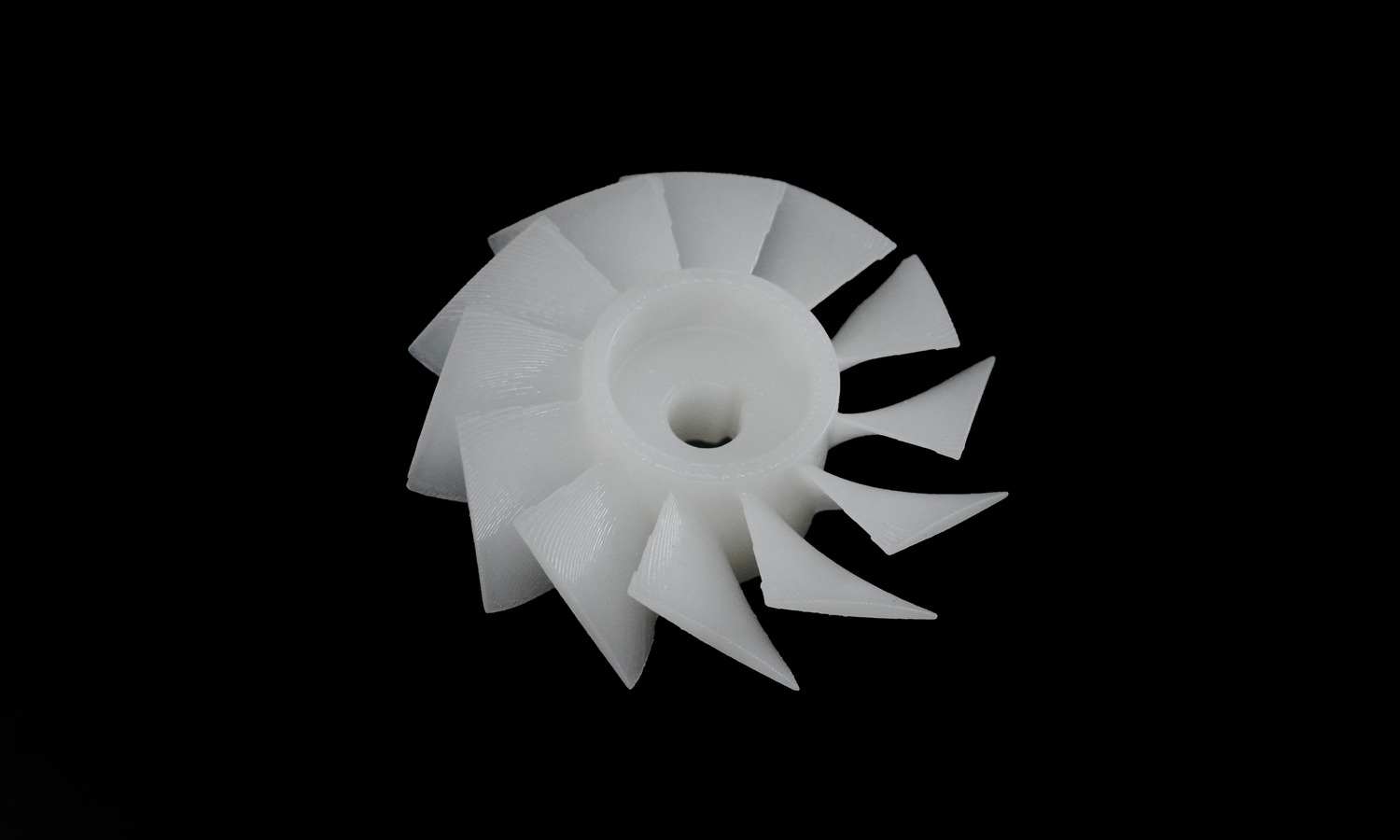

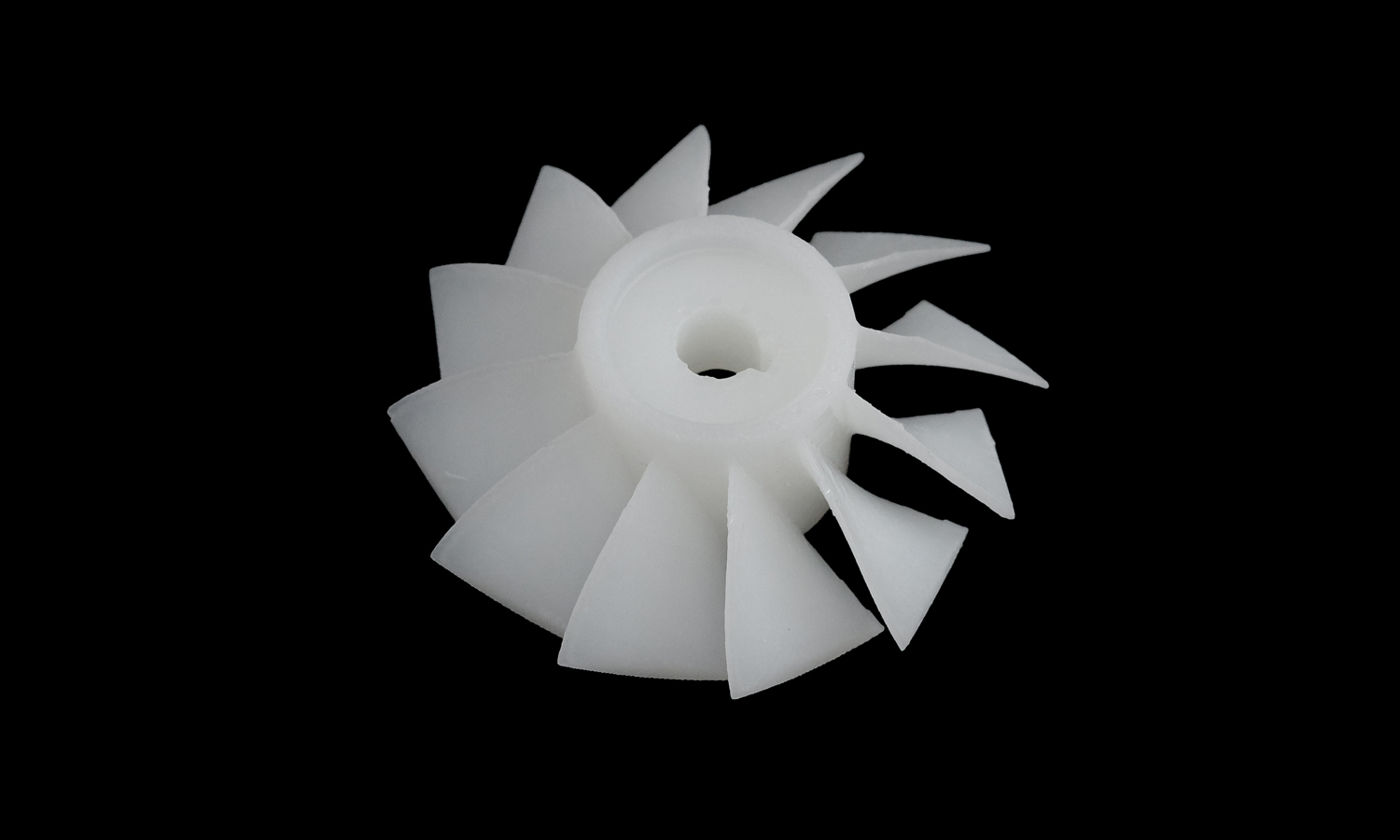

The 3D printed impeller miniature, crafted using Somos Ledo 6060, showcases the remarkable properties of this photosensitive resin, known for its toughness and smooth surface finish. Here’s a detailed look at the key features and quality of the impeller:

Features

- Material: Made from Somos Ledo 6060, a high-performance resin ideal for creating durable and detailed 3D printed parts.

- Design: The impeller features curved blades that are critical for its functionality, ensuring optimal performance in real-world applications.

- Surface Quality: The overall surface of the impeller is relatively smooth, highlighting the resin’s excellent finish. The 0.1mm layer thickness could be witnessed under strong light.

- Edge Definition: The edges of the blades are not well-defined, which could impact the efficiency and functionality of the impeller.

Conclusion

Despite some imperfections in edge definition and noticeable layer lines, the SLA 3D printed impeller miniature demonstrates the potential of Ledo 6060 resin for creating functional and durable parts. The high precision and smooth surface finish achievable with this material make it a valuable choice for various applications.

At FacFox, we specialize in providing top-tier 3D printing services using advanced materials like Ledo 6060 resin. Our state-of-the-art SLA 3D printing technology ensures that every component meets the highest standards of quality and performance. From prototyping to full-scale production, our expert team is dedicated to delivering solutions that exceed your expectations.

Elevate your projects with FacFox’s SLA 3D printing services. Contact us today to learn more about our Ledo 6060 resin materials and how we can bring your designs to life!

Solution

- Step 1: A 3D model of the impeller miniature was designed.

- Step 2: The 3D model was sliced into multiple thin layers.

- Step 3: Support structures were generated to ensure proper curing.

- Step 4: The build platform was lowered into a vat of Somos Ledo 6060 resin.

- Step 5: A UV laser beam cured the contours of each layer, solidifying the resin.

- Step 6: The build platform was raised after each layer’s curing.

- Step 7: Fresh resin was refilled into the vat as needed.

- Step 8: These steps were repeated until the entire impeller was built.

- Step 9: The printed impeller was removed from the build platform.

- Step 10: The impeller was washed to remove uncured resin.

- Step 11: The impeller was post-cured with UV light to strengthen the material.

- Step 12: Support structures were removed from the impeller.