- Merry Christmas! Wishing you a joyful holiday filled with warmth and inspiration!

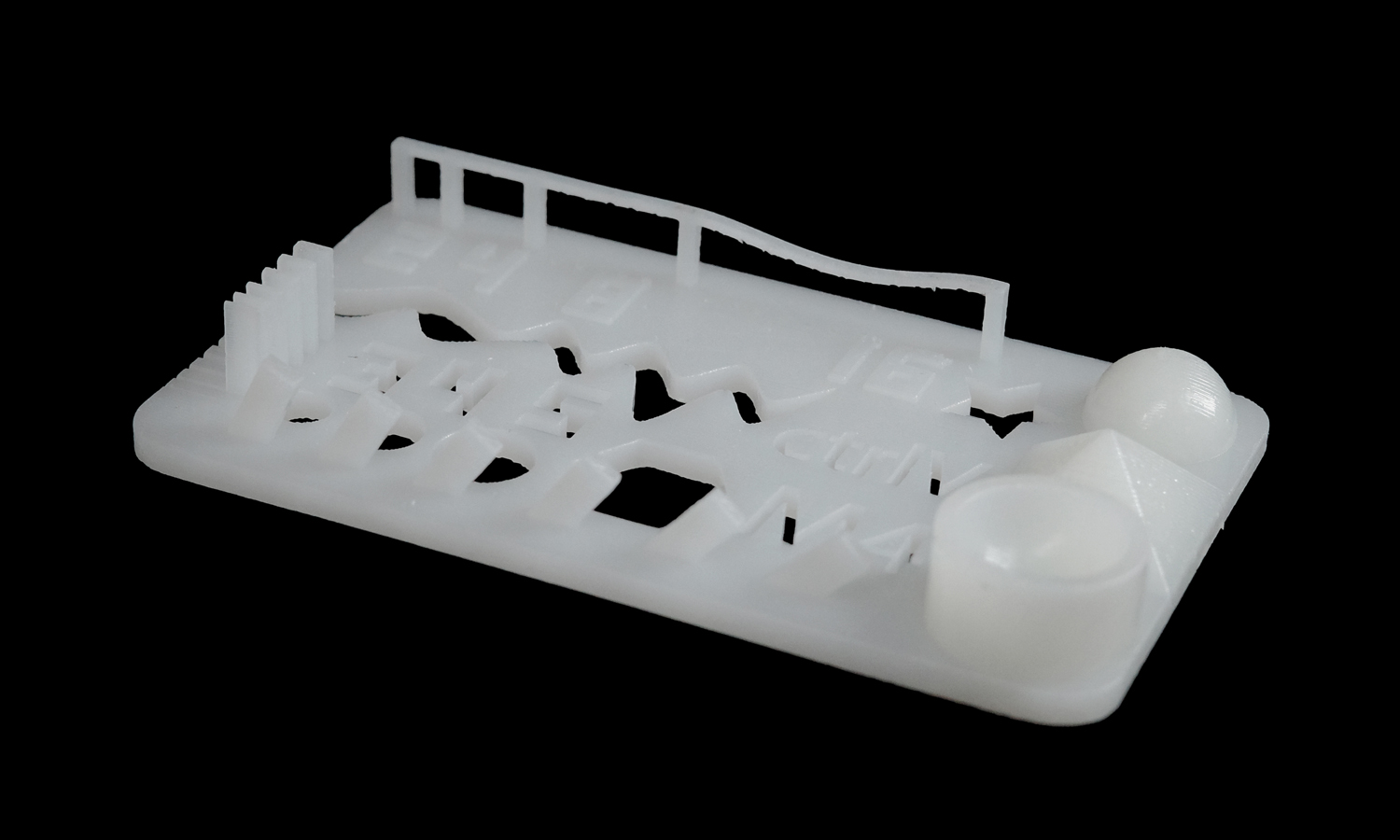

- SLA High-temp Resin-220┬░C 3D Printed Test Unit

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

Introducing our meticulously crafted SLA 3D Printed Ledo 6060 Resin Test Model, designed to highlight the exceptional capabilities and quality of Ledo 6060 resin. This test model showcases the intricate details and precision that can be achieved using this high-performance material, making it an ideal choice for various applications.

Features of the Test Model

The test model includes a variety of features to assess different aspects of 3D printing performance:

- Embossed Numbers and Text: The model features clearly visible embossed numbers and text, demonstrating excellent detail retention and the ability to reproduce fine features accurately.

- Geometric Shapes: The test model includes a wavy line, a star, a hexagon, and several circular shapes of different sizes, showcasing the printer’s capability to handle complex geometries and intricate designs.

- Cut-Out Elements: With cut-out numbers, letters, and shapes, the model highlights the precision of internal geometries. However, the edges of these cut-outs are not clean and sharp, requiring embellishment with a knife to achieve the desired finish.

- Overhang Bridges: The model features overhang bridges of varying lengths, including a 16mm bridge that has shown deformation, and 4mm and 8mm bridges with noticeable support marks. These elements test the printer’s capability to handle unsupported horizontal structures.

Experience the FacFox Advantage

At FacFox, we specialize in providing top-tier 3D printing services using advanced materials like Ledo 6060 resin. Our state-of-the-art SLA 3D printing technology ensures that every component meets the highest standards of quality and performance. From prototyping to full-scale production, our expert team is dedicated to delivering solutions that exceed your expectations.

Elevate your projects with FacFox’s SLA 3D printing services. Contact us today to learn more about our Ledo 6060 resin materials and how we can bring your designs to life!

Solution

- Step 1: Data Preparation. The CAD data was prepared for SLA printing by optimizing for printability, including the addition of support structures.

- Step 2: Resin Tank Preparation. The SLA 3D printer’s resin tank was filled with Ledo 6060 resin.

- Step 3: Printing. The 3D printing process was initiated, and the model was built layer by layer using a laser beam that cured the resin.

- Step 4: Support Removal. After printing, the support structures were carefully removed from the model using appropriate tools or techniques.

- Step 5: Washing. The model was washed to remove any residual uncured resin.

- Step 6: Curing. The model was cured using UV light or thermal curing to solidify the printed part and improve its mechanical properties.