SLA 3D Printed Resin Full-scale Sports Car Body Shell

- DMLS 3D Printed Titanium Bike Saddle Clamp Kit

- Urethane Rubber Batman Cowl Cast from SLA 3D Printed Resin Pattern

Posted on 2024-10-03 in Automotive В· жұҪиҪҰ

Process 3D Print, Support Removal, Post Curing, Polish

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 8 workdays

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 8 workdays

Gallery

About Project

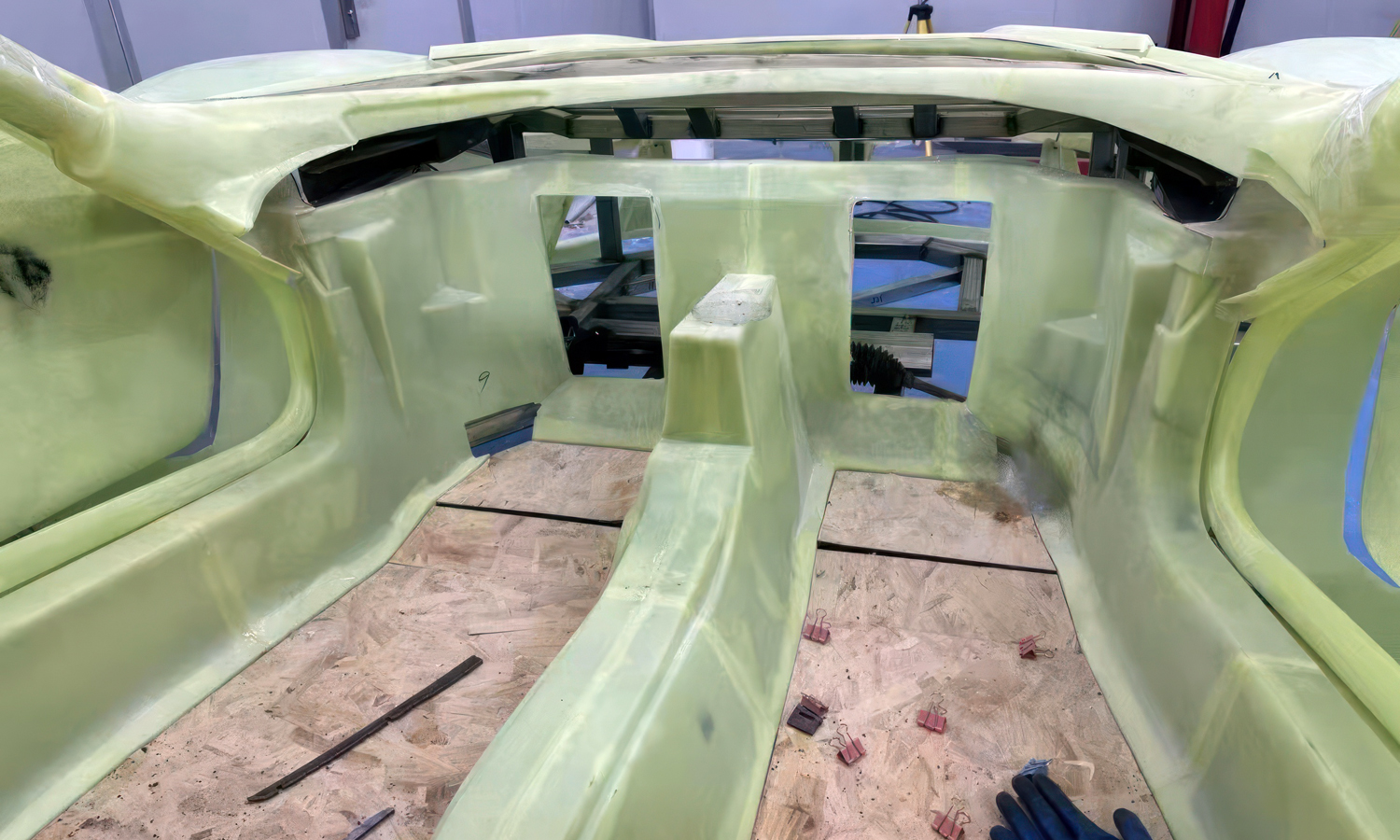

At FacFox, we are at the forefront of innovation, bringing you the latest in SLA 3D printing technology. Our recent project showcases a full-scale sports car body shell, expertly crafted from high-quality resin. This cutting-edge approach not only speeds up the prototyping process but also ensures unmatched precision and detail.

Project Highlights

- Full-scale Sports Car Body Shell: Printed and meticulously assembled in our advanced workshop, this body shell exemplifies modern automotive design and manufacturing excellence.

- Sleek, Aerodynamic Design: The body shell features smooth curves and a low profile, characteristic of high-performance sports cars, ensuring it stands out in both form and function.

- Yellowish-Green Resin: The shell has a distinctive yellowish-green hue due to the resin used, which will be painted during the post-processing stage.

- Mobility and Flexibility: Mounted on a frame with casters, the body shell can be easily moved around the workshop, facilitating seamless assembly and inspection processes.

- Incomplete Shell: Currently missing wheels, doors, and other external features, this shell serves as an ideal prototype for further development and customization.

Why Choose FacFox for Automotive Prototyping?

- Advanced Technology: Our SLA 3D printing services utilize the latest advancements in resin printing, ensuring high precision and exceptional quality.

- Expertise and Experience: With years of experience in the field, our team of experts is dedicated to delivering top-notch prototyping solutions tailored to your needs.

- Speed and Efficiency: Our streamlined processes and advanced equipment allow us to produce prototypes quickly, helping you bring your designs to life faster than ever before.

- Customization and Flexibility: We offer a wide range of materials and finishes, allowing you to customize your prototypes to meet specific requirements and preferences.

Get Started with FacFox Today!

Transform your automotive prototyping projects with FacFox’s SLA 3D printing services. Contact us today to learn more about how we can help you achieve your design goals and stay ahead of the competition.

рҹ“һ Contact Us: info@facfox.com рҹҢҗ Visit Our Website: facfox.com

Experience the future of automotive prototyping with FacFox – where innovation meets precision.

Solution

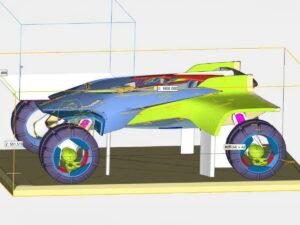

- Step 1: Design Creation. The car body shell was designed using advanced CAD software to ensure precision and accuracy.

- Step 2: Model Slicing. The 3D model was sliced into smaller, manageable parts to prevent deformation during the printing process.

- Step 3: Printing Preparation. The SLA 3D printers were calibrated, and the SLA Tough Resin material was prepared for printing.

- Step 4: Part Printing. Each part of the car body shell was printed layer by layer using SLA 3D printing technology. The resin was cured with a UV laser to solidify each layer.

- Step 5: Post-Processing. The printed parts were carefully removed from the printer and cleaned to remove any excess resin.

- Step 6: Curing. The parts were placed in a UV curing chamber to ensure they were fully hardened and stable.

- Step 7: Assembly Preparation. The edges of the printed parts were smoothed and prepared for assembly.

- Step 8: Assembly. The individual parts were assembled in the workshop. The parts were aligned and bonded together to form the complete car body shell.

- Step 9: Surface Finishing. The assembled body shell was sanded and smoothed to achieve a uniform surface.

- Step 10: Mounting. The completed body shell was mounted on a frame with casters to facilitate mobility within the workshop.

- Step 11: Inspection. The assembled car body shell was thoroughly inspected to ensure all parts were correctly aligned and bonded.