Material Metal

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

The orthodontic industry is ripe for innovation. Traditional braces often lead to suboptimal results due to their standardized design and manual application. However, a new era of personalized orthodontics is dawning, thanks to advancements in 3D printing technology.

The Limitations of Traditional Braces

- One-size-fits-all: Pre-fabricated brackets often do not account for the unique characteristics of each patient’s teeth and bite.

- Time-consuming adjustments: Achieving the ideal alignment can require extensive wire bending and bracket repositioning.

- Manual bonding errors: Human error can lead to inaccurate bracket placement, affecting treatment outcomes.

The Power of 3D Printed Custom Brackets

- Personalized fit: By leveraging 3D scanning and design software, orthodontists can create custom brackets that perfectly match each patient’s individual anatomy.

- Enhanced comfort: The precise fit of 3D-printed brackets can significantly reduce discomfort and irritation.

- Improved efficiency: The streamlined digital workflow eliminates the need for complex molds and manual processes, leading to faster treatment times.

- Greater accuracy: Automated 3D printing ensures highly accurate and repeatable results, minimizing the risk of errors.

LPBF 3D Printing: A Game-Changer for Orthodontics

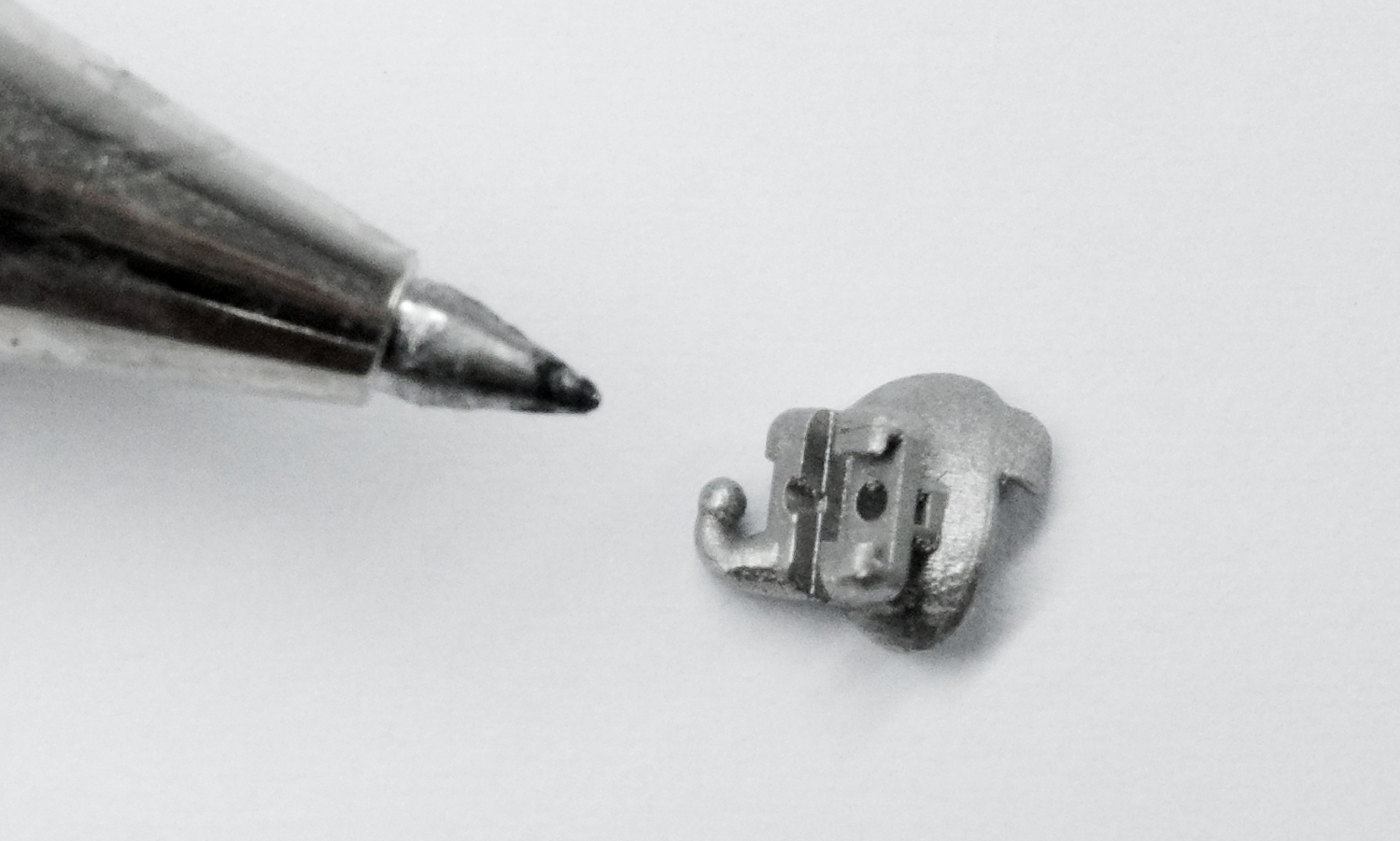

Laser Powder Bed Fusion (LPBF) 3D printing, offers unparalleled precision and flexibility for creating custom orthodontic brackets. By using a high-powered laser to selectively melt metal powder, it’s possible to produce intricate and complex geometries with micron-level accuracy. Stainless steel 316L, a biocompatible material commonly used in medical implants, is an ideal choice for these applications due to its strength and corrosion resistance.

Experience the Future of Orthodontics with FacFox

FacFox is a leading provider of micron-level metal 3D printing services. Our advanced LPBF systems enable us to create custom orthodontic brackets with exceptional detail and precision. By partnering with FacFox, orthodontists can offer their patients the benefits of personalized treatment, improved outcomes, and shorter treatment times.

- Custom bracket design: Our team of experts can work with you to design and manufacture custom brackets that meet your specific requirements.

- Fast turnaround times: Benefit from our efficient production process and receive your custom brackets quickly.

- Uncompromising quality: Our commitment to quality ensures that every bracket meets the highest standards of precision and biocompatibility.

Ready to revolutionize your orthodontic practice? Contact FacFox today to learn more about our micron-level metal 3D printing services and how they can benefit your patients.

Solution

- Step 1: Design Creation.┬ĀThe orthodontic bracket design was created using CAD (Computer-Aided Design) software based on the patient’s specific dental anatomy and occlusion.

- Step 2: Preparation of the Printer.┬ĀThe LPBF 3D printer was prepared by filling the build chamber with SS316L stainless steel powder.

- Step 3: Layer-by-Layer Printing.┬ĀThe design file was uploaded to the 3D printer. The printer then used a high-powered laser to selectively melt and fuse the stainless steel powder layer by layer, following the design specifications.

- Step 4: Cooling and Solidification.┬ĀAfter the printing process, the printed bracket was allowed to cool and solidify within the build chamber.

- Step 5: Removal from Build Chamber.┬ĀThe solidified bracket was carefully removed from the build chamber.

- Step 6: Post-Processing.┬ĀThe bracket underwent several post-processing steps, including support removal, surface finishing, and heat treatment to enhance its mechanical properties and ensure a smooth surface.

- Step 7: Quality Inspection.┬ĀThe finished bracket was inspected for any defects or deviations from the design specifications. Precision measurements were taken to ensure accuracy.

- Step 8: Cleaning and Sterilization.┬ĀThe bracket was cleaned and sterilized to ensure it was safe for use in the patient’s mouth.

- Step 9: Customization for Patient.┬ĀThe bracket was customized further, if necessary, to fit the patient’s unique dental structure perfectly.

- Step 10: Final Fitting.┬ĀThe customized bracket was then fitted onto the patient’s teeth, ensuring comfort and functionality.