- ColorJet 3D Printed Graduate Roommates’ Full-color Statue

- SLA 3D Printed Large-format Pink Nine-tail Fox Resin Statue

Material Resin

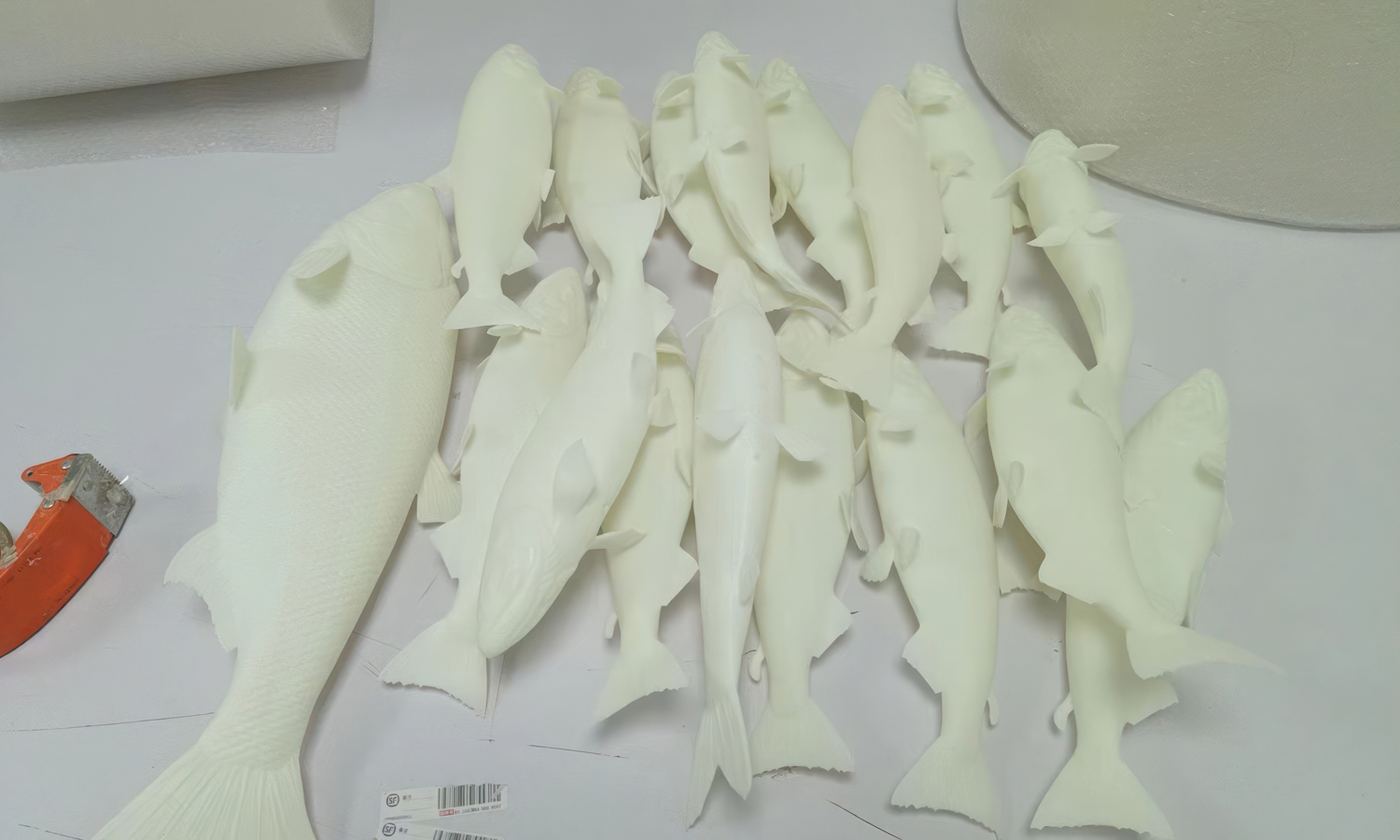

Quantity 24 pcs

Price Range $1-100

Lead Time 29 workdays

Gallery

About Project

FacFox is thrilled to unveil our latest innovation: lifelike resin fish models, perfect for captivating museum visitors. These meticulously crafted models are 3D printed using SLA technology, ensuring exceptional detail and accuracy.

From Ocean to Exhibit

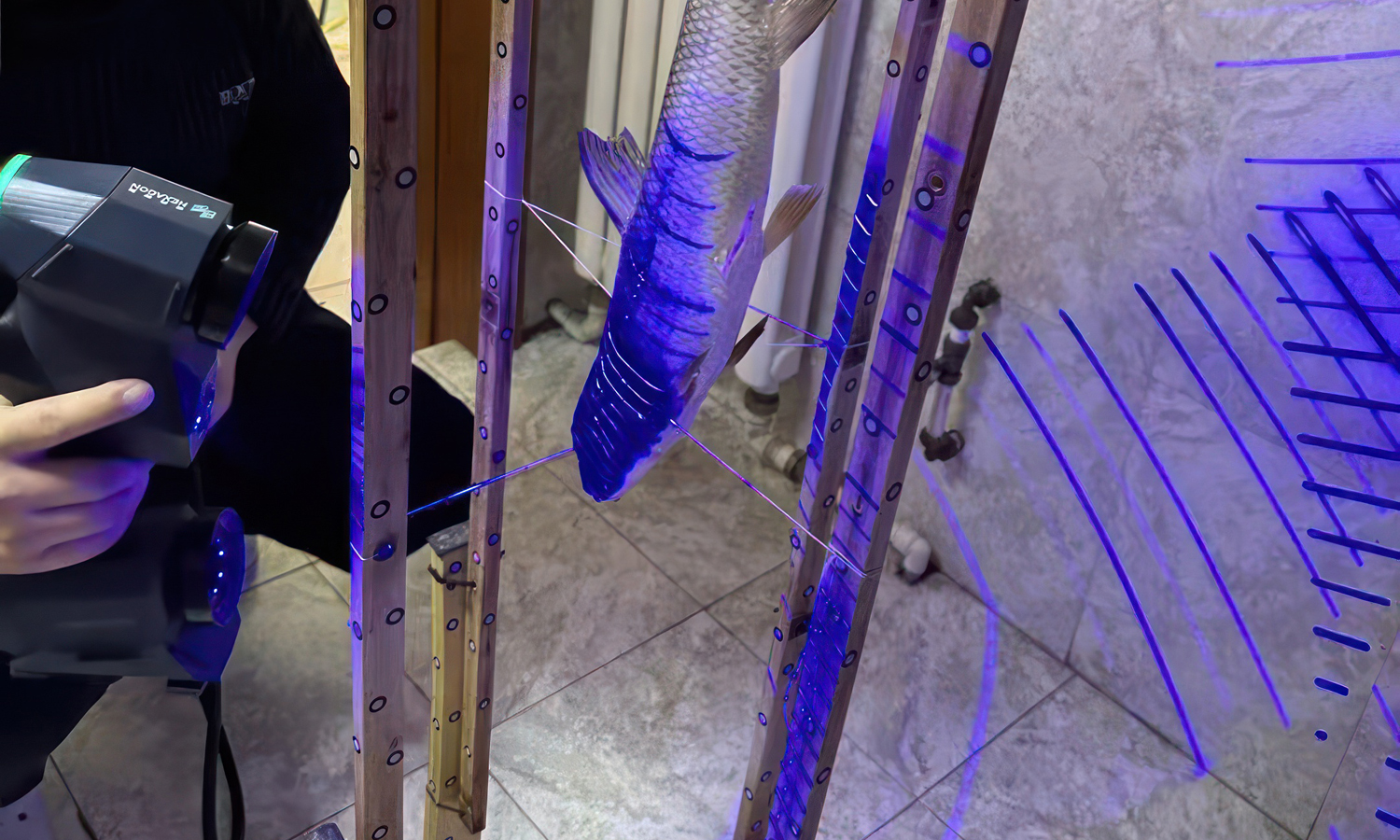

Our process begins with capturing the essence of real fish through advanced 3D scanning. Every scale, fin, and nuance is preserved, resulting in models that are virtually indistinguishable from their living counterparts. Skilled artisans then hand-paint each model, bringing out the vibrant colors and intricate patterns that make these aquatic creatures so mesmerizing.

A Diverse Underwater World

Our collection boasts a wide array of fish species, each with its own unique charm. From the graceful elegance of a sturgeon to the playful energy of a carp, our models cater to diverse exhibit themes. The varying sizes, shapes, and colors of these fish create a dynamic and visually stunning display.

Immersive Museum Experiences

To enhance the exhibit’s impact, we mount each fish model on a sturdy metal base and arrange them in a captivating composition. Imagine a school of fish seemingly swimming towards the viewer, creating an immersive experience.

Elevate Your Museum with FacFox

FacFox offers comprehensive 3D printing and scanning services to bring your museum exhibits to life. Let us help you create unforgettable experiences for your visitors.

Solution

- Step 1: Scanning. Real fish specimens were scanned using high-resolution 3D scanners to capture their intricate details and shapes.

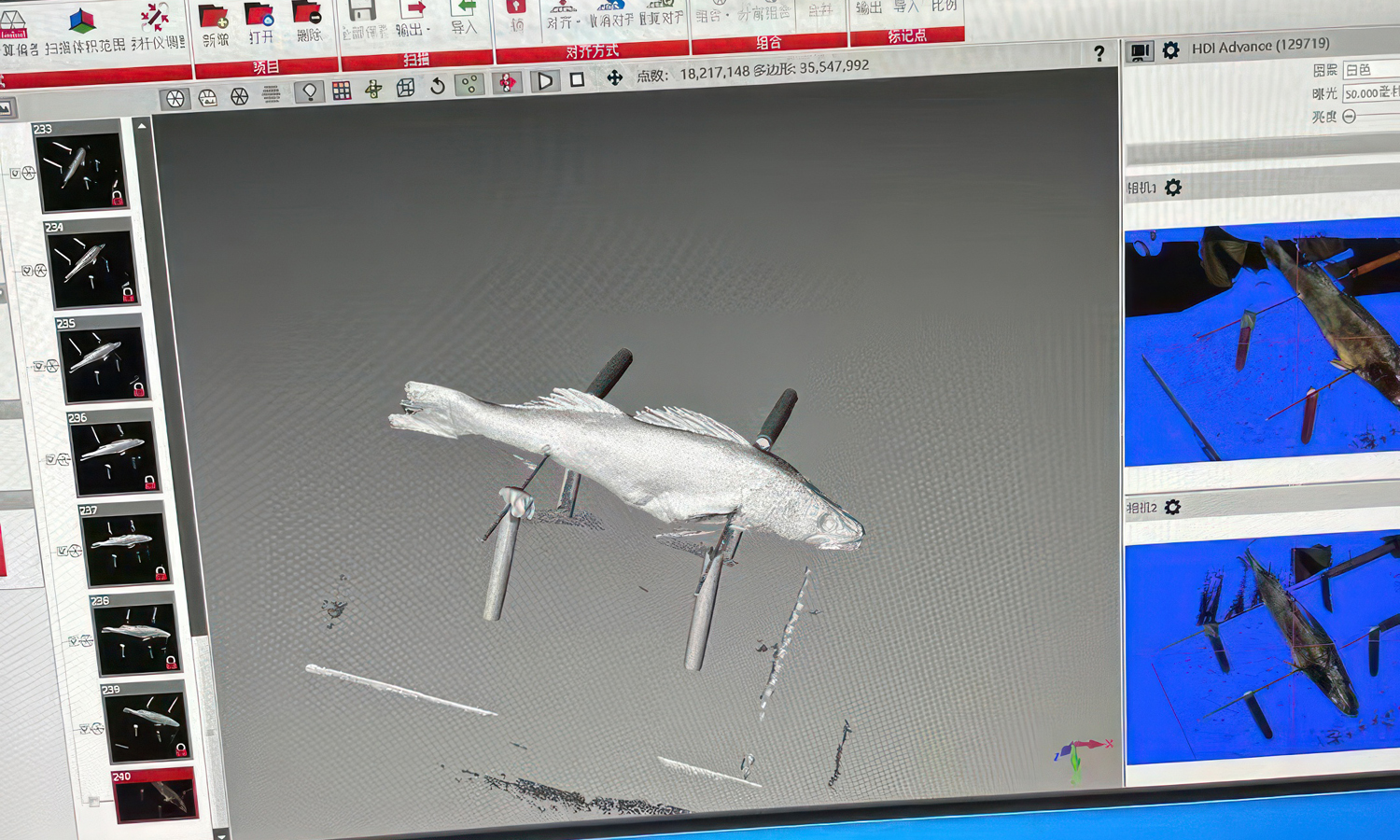

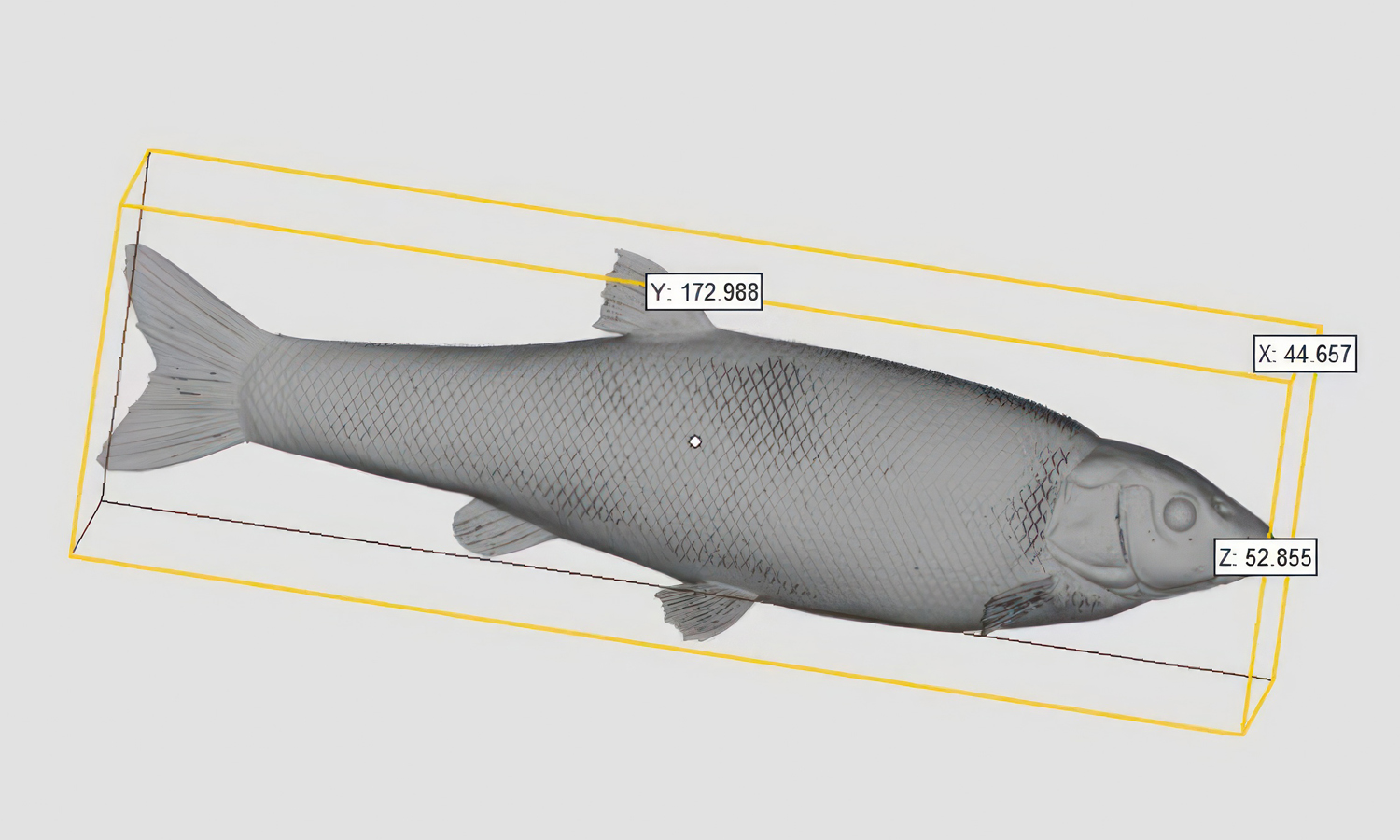

- Step 2: Model Preparation. The scanned data were processed and cleaned up using 3D modeling software to ensure accuracy and remove any imperfections.

- Step 3: Slicing. The 3D models were sliced into thin layers using specialized software, preparing them for the SLA 3D printing process.

- Step 4: Printing. The sliced models were printed using an SLA 3D printer. A UV laser was used to cure the liquid SLA Generic Resin layer by layer, creating solid objects.

- Step 5: Post-Processing. The printed models were removed from the printer and cleaned to remove any uncured resin. Supports were carefully detached, and the models were further cured under UV light to ensure complete hardening.

- Step 6: Sanding and Smoothing. The surfaces of the models were sanded and smoothed to eliminate any layer lines or imperfections, preparing them for painting.

- Step 7: Priming. A primer was applied to the models to create a smooth and uniform surface, which also helped the paint adhere better.

- Step 8: Painting. Experienced painters meticulously painted the models using high-quality paints to replicate the natural colors and patterns of the fish species.

- Step 9: Mounting. Each painted fish model was mounted on a stand with a metal base, providing stability and a professional appearance.

- Step 10: Arrangement. The finished models were arranged by size and placed on tables in a manner that resembled a group of fish swimming towards the right, creating a dynamic and visually appealing display.