Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

Looking for a high-quality prototype for your next mechanical product exhibition? Look no further than FacFox’s 3D printing service!

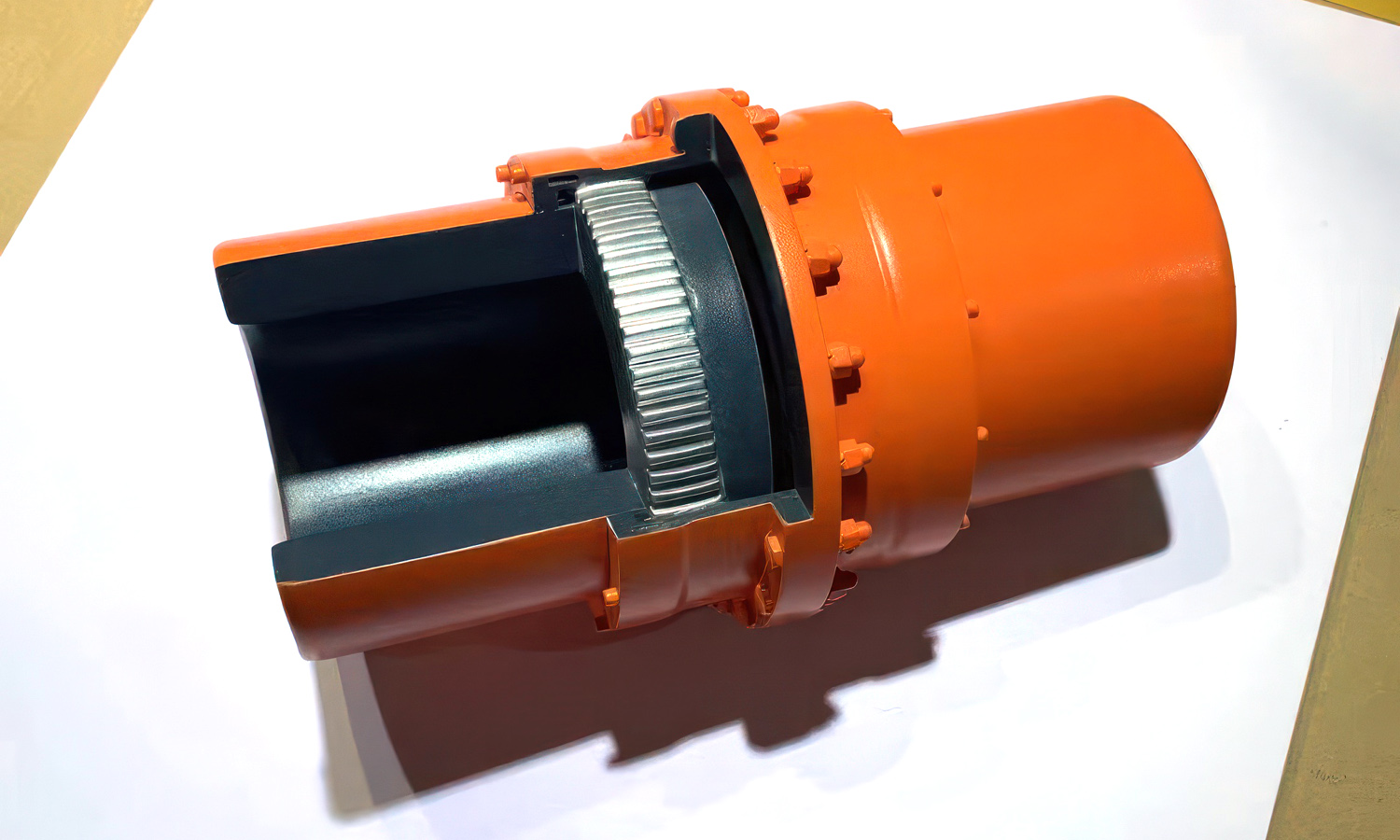

Transmission shafts are vital components in countless machines and vehicles, responsible for transferring rotational motion and power. Their designs can range from simple to highly complex, depending on their application.

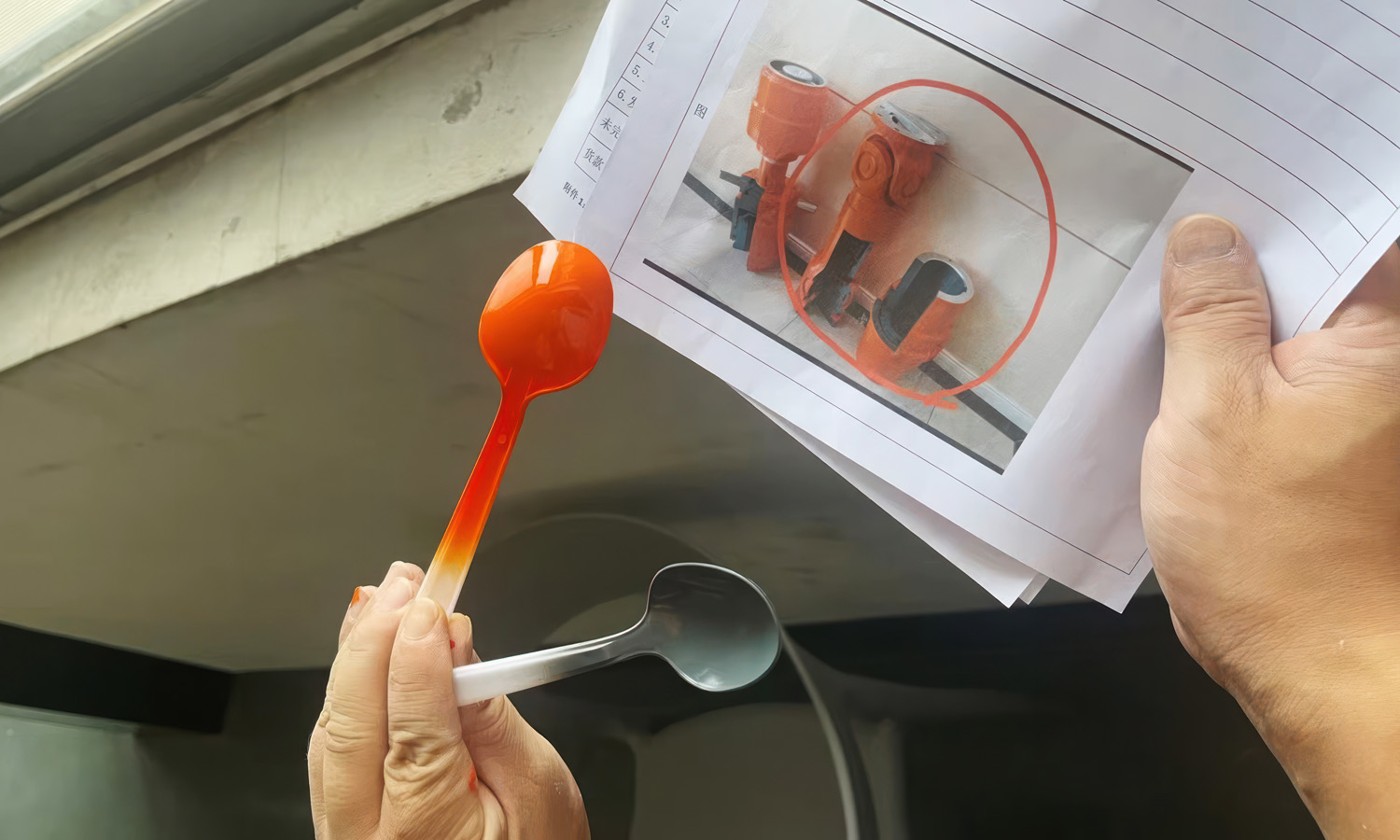

At FacFox, we recently created a disassembled prototype transmission shaft for a client, showcasing the intricate details of their new product design. Here’s a breakdown of the project:

- Material: SLA ABS-like Resin

- Color: Primarily orange and grey, as specified by the client

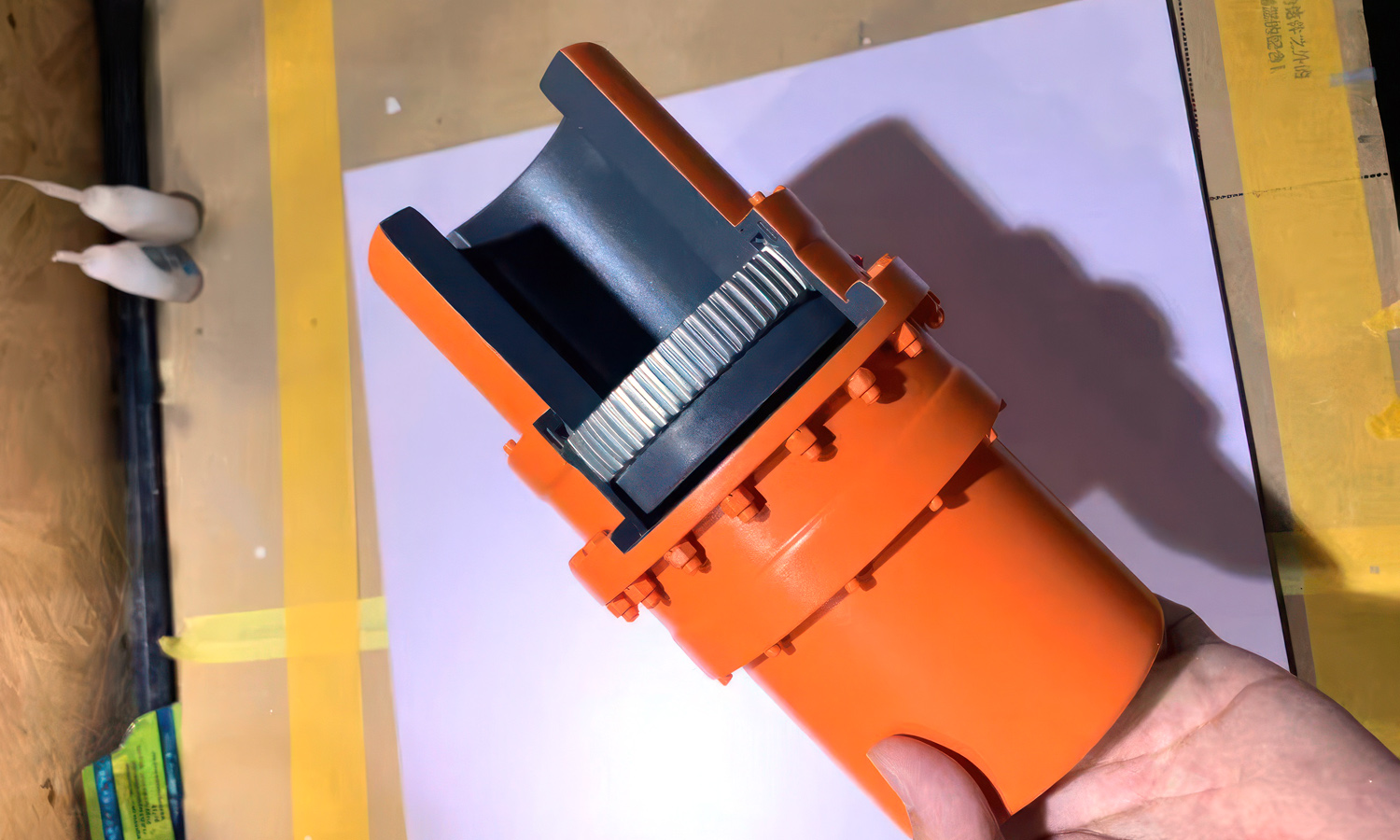

- Design: Disassembled to reveal internal structure

- Components: Two cylindrical sections with capped ends, featuring internal gears, bearings, and other intricate parts.

This prototype effectively highlights the product’s design complexity and functionality, making it a perfect exhibition centerpiece.

Why Choose FacFox for Your Mechanical Product Prototyping?

FacFox offers a wide range of 3D printing solutions specifically tailored for the mechanical product industry. Here’s what sets us apart:

ŌĆó High-Precision Printing: Our SLA technology ensures exceptional detail and dimensional accuracy, ideal for intricate mechanical parts.

ŌĆó Diverse Material Selection: We offer a variety of materials with properties suited for different mechanical applications, from strong and durable to flexible and heat-resistant.

ŌĆó Expert Support: Our team of experienced engineers can help you choose the right printing process and material for your project, ensuring optimal results.

Showcase Your Mechanical Innovations with FacFox

FacFox’s 3D printing service can help you bring your mechanical product ideas to life. With our advanced technology and expertise, we can create high-quality, functional prototypes that will impress potential customers and investors.

Contact FacFox today to discuss your prototyping needs and get a quote!

Solution

- Step 1: Design Phase. The transmission shaft prototype was initially designed using computer-aided design (CAD) software, where every detail was carefully crafted to match the exhibition specifications.

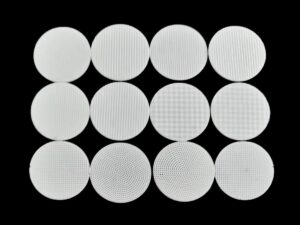

- Step 2: File Preparation. The CAD file was then converted into a format suitable for 3D printing, and the design was sliced into thin horizontal layers.

- Step 3: Machine Setup. The SLA 3D printer was prepared, with the resin tank filled with a photopolymer resin suitable for the prototype.

- Step 4: Printing Process. The build platform was lowered into the resin vat, and the printing process was commenced. A UV laser traced the cross-section of the prototype onto the surface of the liquid resin, curing and solidifying it layer by layer.

- Step 5: Layer Formation. As each layer was completed, it was gently moved to allow fresh resin to flow beneath it, and the next layer was cured on top.

- Step 6: Support Removal. After the printing was finished, the prototype was carefully removed from the build platform, and any excess resin was washed away. Supports that were added during the printing process were meticulously removed.

- Step 7: Post-Curing. The prototype was then placed in a UV chamber to ensure complete curing of the resin, enhancing its strength and stability.

- Step 8: Surface Finishing. The surface of the prototype was smoothed and finished to achieve the desired quality and appearance for the exhibition. It was painted into appointed Pantone colors with spray guns.

- Step 9: Quality Check. The completed prototype underwent a thorough inspection to ensure it met all the required dimensions and quality standards.

- Step 10: Presentation Preparation.┬ĀFinally, the prototype was mounted or displayed as needed for the exhibition, showcasing the detailed craftsmanship and design of the transmission shaft.