Gallery

About Project

Do you want to make your 3D-printed parts stand out from the crowd? Do you want to add some contrast and elegance to your designs? Do you want to enhance the appearance and durability of your parts? If you answered yes to any of these questions, then you need to try MJF 3D Printed PP Sample Label Dyed Black.

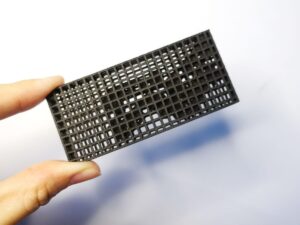

PP, or Polypropylene, is a versatile and robust material that can be 3D printed with MJF, or Multi Jet Fusion, technology. MJF is a powder-based 3D printing process that uses a thermal inkjet array to selectively fuse layers of fine-grained PP powder. MJF can produce parts with high resolution, dimensional accuracy, and mechanical properties that are nearly isotropic. MJF also allows for high reusability of the powder, reducing waste and cost.

One of the most popular post-processing options for MJF 3D-printed PP parts is dyeing. Dyeing is a process that involves immersing the parts in a hot bath of colorant. Dyeing can change the color of the parts from the natural gray to black or other colors. Dyeing can also improve the surface finish and reduce the porosity of the parts. Dyeing can give your parts a more uniform and professional look.

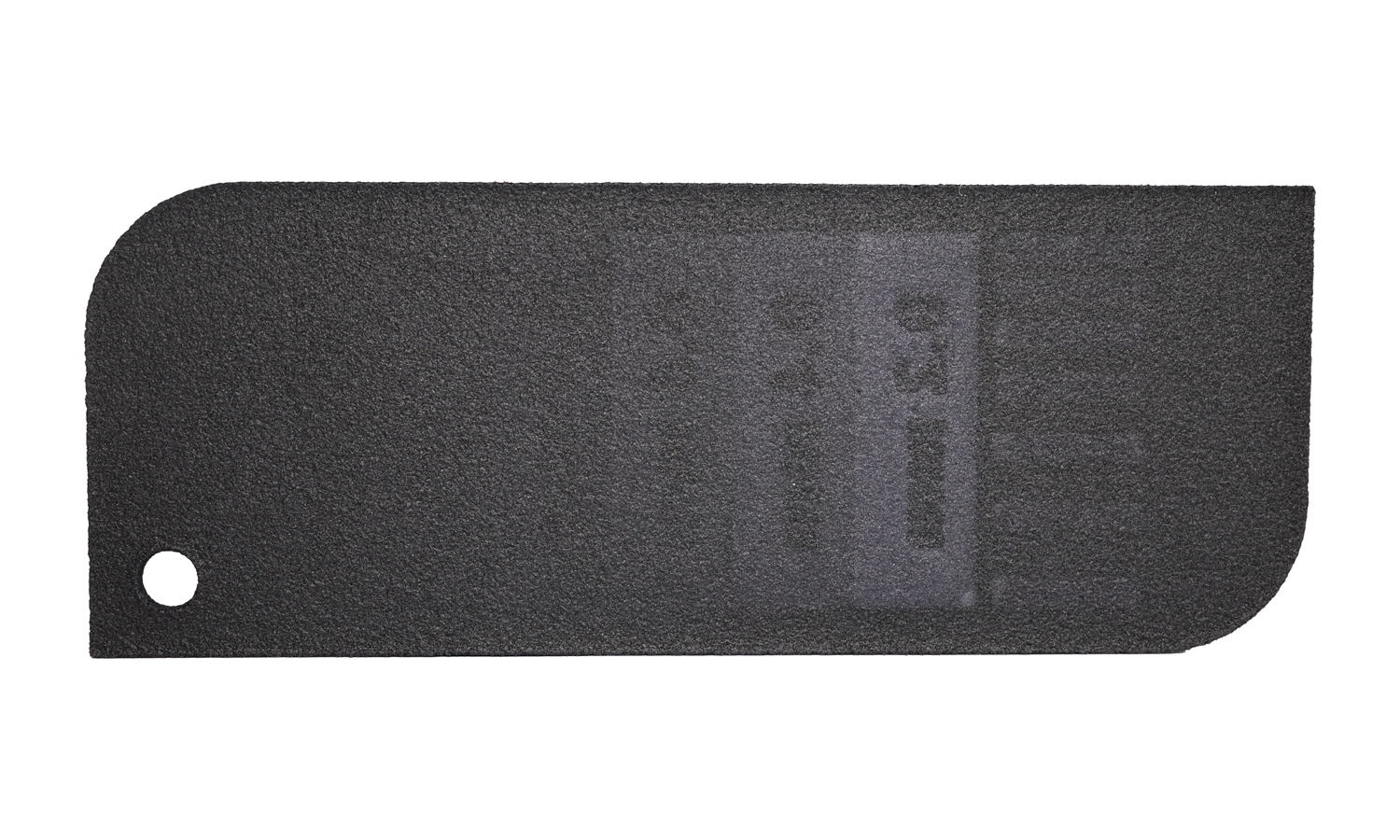

To show you the amazing difference that dyeing can make for your MJF 3D printed PP parts, we have created a sample label with dyed black finishing. This label is a demonstration of what MJF can do with PP material. The label has a rectangular shape and different thicknesses of PP material in the middle. You can see how MJF can print thin features with PP material and how smooth the surfaces are. You can also see how dyeing can enhance the contrast and elegance of the label.

Do you want to get your own MJF 3D printed PP parts with dyed black finishing? Then you need to visit FacFox. FacFox is the ultimate online manufacturing service provider that offers a wide range of manufacturing services with rich materials, fast turnaround, and low cost. FacFox has state-of-the-art MJF printers and skilled engineers who can help you with your design and production needs. Whether you need prototypes or end products, FacFox can make your parts with the highest quality and efficiency. Visit their website facfox.com to get an instant quote and start your project today.

Solution

- Step 1: A 3D model of the sample label was created using CAD software. The model had a rectangular shape and different thicknesses of PP material in the middle.

- Step 2: The 3D model was uploaded to the FacFox website and an order was placed for MJF 3D printing with raw finishing. The order details included the material, quantity, and delivery options.

- Step 3: The order was processed by FacFox and the 3D model was sliced into thin layers by software. The software also generated a print file that contained the instructions for the MJF printer.

- Step 4: The print file was sent to the MJF printer and the printing process began. The printer had a build chamber that contained a bed of fine-grained PP powder. The printer also had a thermal inkjet array that moved across the powder bed and selectively deposited a fusing agent on the areas that corresponded to the cross-sections of the sample label.

- Step 5: The printer also applied a detailing agent on the edges of the part to improve the surface quality. The printer then used an infrared lamp to heat up the powder bed and fuse the PP particles together. It repeated this process for each layer until the sample label was completed.

- Step 6: The sample label was removed from the powder bed and cleaned with compressed air. The excess powder was recycled for future use. The label was soaked in a dye solution for minutes.

- Step 7: The sample label was then inspected for quality and packed for shipping. The sample label was delivered to the customer with raw finishing, which means that no further post-processing was done on the part.