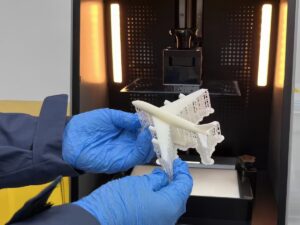

- FDM 3D Printed White Polycarbonate Large Spacer Prototype

- SLM 3D Printed Aluminum 6061 Smart One-Hand Bottle Opener

Material Rubber

Quantity 1 pcs

Price Range $100-1,000

Lead Time 2 workdays

Gallery

About Project

Selective Laser Melting (SLM) is a cutting-edge technology that allows for the creation of complex and high-performance metal parts using a laser to fuse metal powder layer by layer. SLM can produce parts with excellent mechanical properties, high hardness, good thermal conductivity, and easy machinability. SLM is ideal for many tooling applications, such as injection molding, die casting, punching, extrusion, and more.

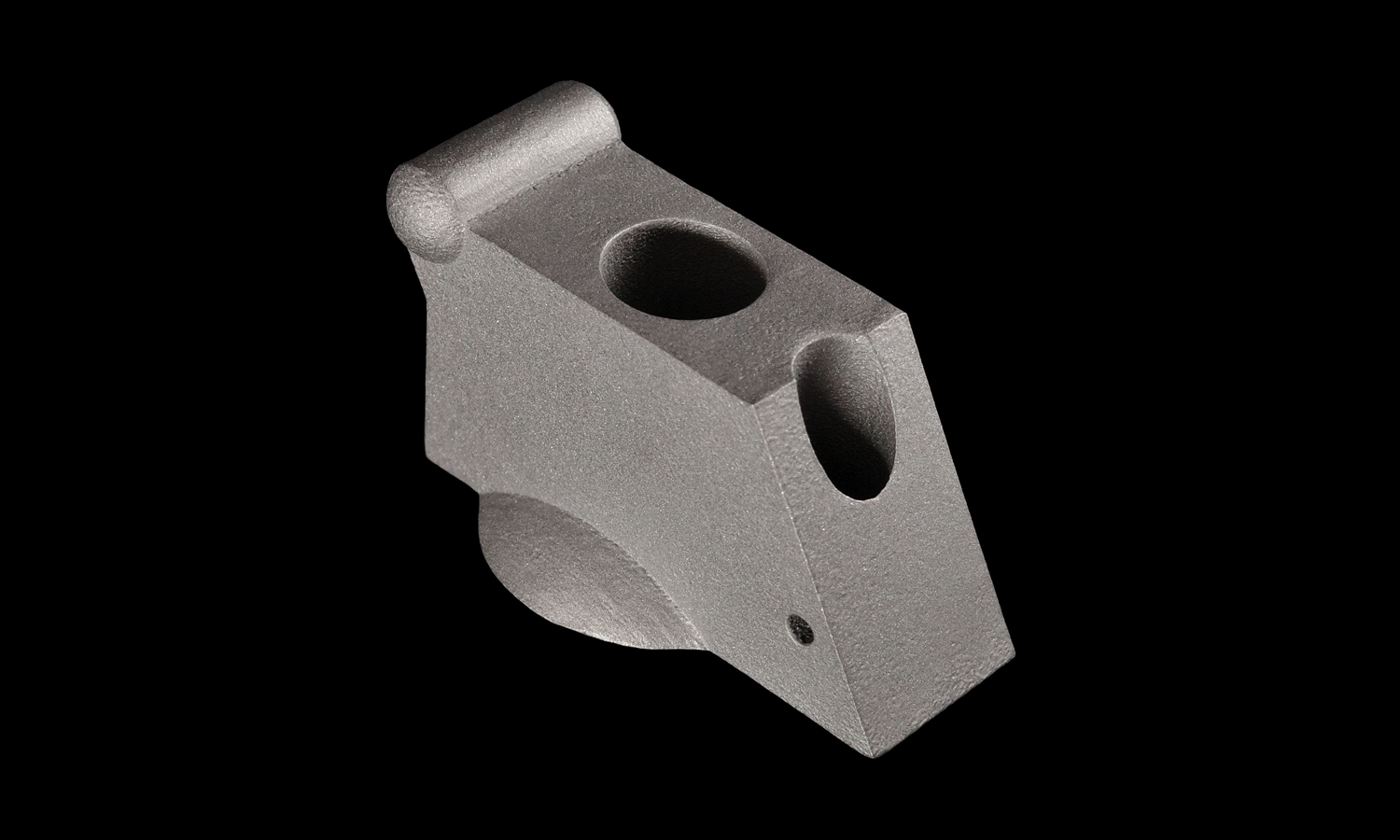

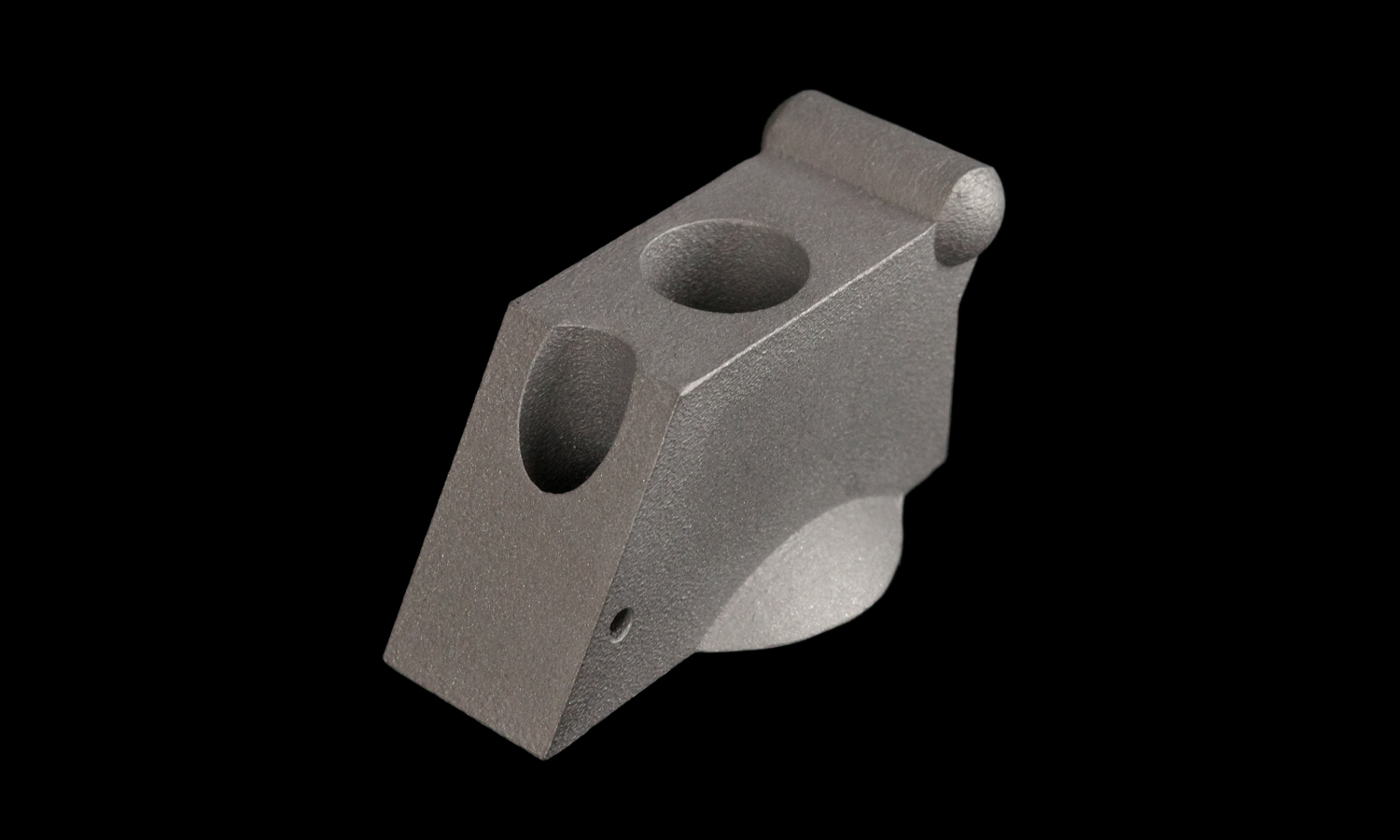

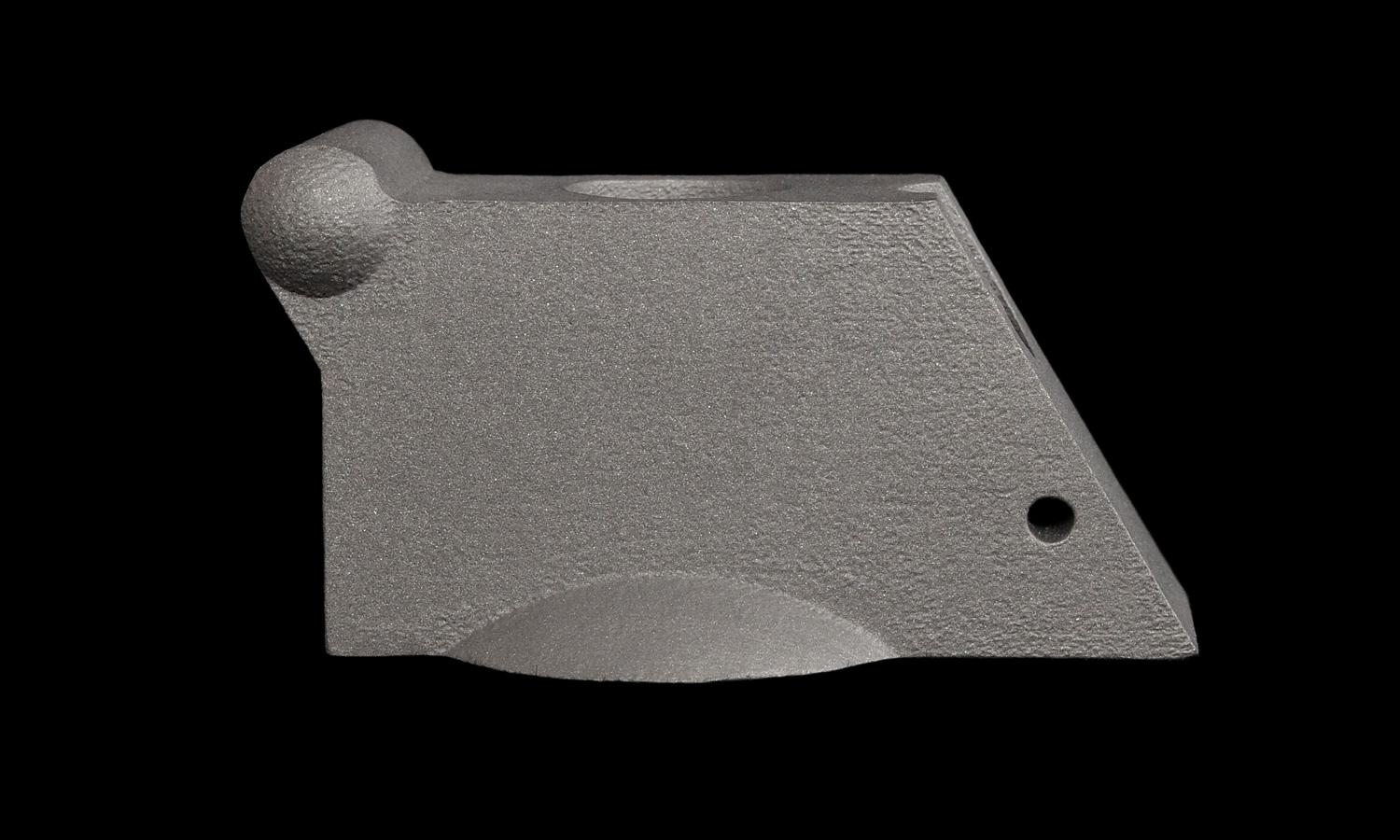

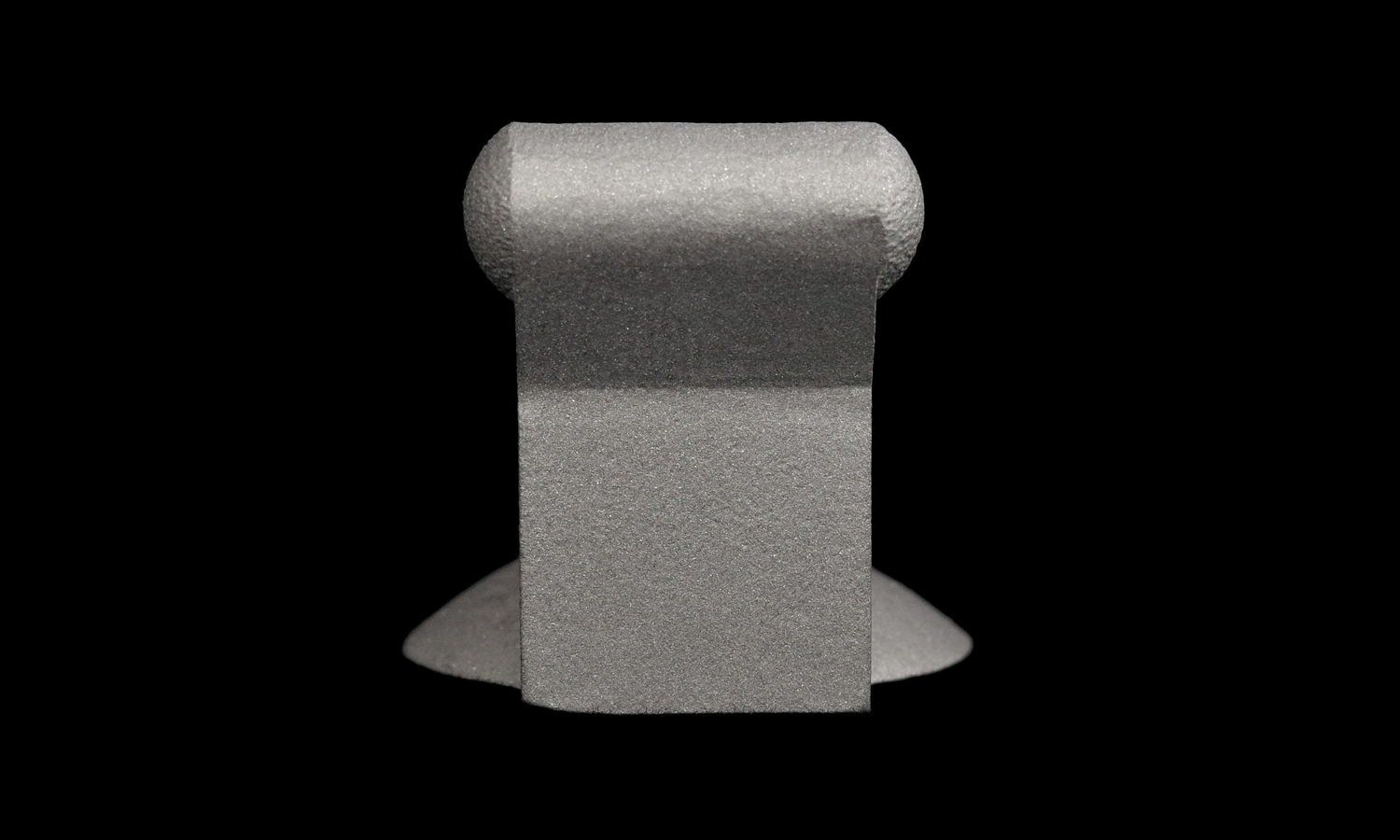

One of our recent projects involved the production of a mechanical prototype using SLM and die steel. The prototype had a unique shape that resembled a right angle trapezoid with a thin rod attached on the top and an oblate spheroid on the bottom. There were also two large holes, one on the top face and one on the front face. The prototype was designed for a confidential purpose and we cannot disclose what it can be used for.

The prototype was printed using Die Steel (DS1), which is a steel powder that has high wear resistance and toughness. The part was easily machinable after the printing process and was post-hardened to more than 50 HRC. The part had a high dimensional accuracy and a smooth surface finish. The part also had complex internal features that would be impossible to achieve with traditional manufacturing methods.

The prototype was printed in less than a week and delivered to the client for testing and evaluation. The client was very satisfied with the quality and performance of the part and praised our SLM service for its speed, flexibility, and cost-effectiveness.

If you are looking for a reliable and professional SLM service provider, look no further than FacFox. FacFox is a leading online platform that offers high-quality metal 3D printing services in China. We have advanced SLM machines and experienced engineers who can handle any project size and complexity. We can print parts from various metal materials, such as stainless steel, aluminum, titanium, copper, nickel alloy, and more. We also offer post-processing services, such as polishing, heat treatment, coating, etc.

FacFox is your one-stop shop for all your metal 3D printing needs. Whether you need prototypes, low-volume production, or custom parts, we can help you achieve your goals with our SLM service. Contact us today to get a free quote and start your project with us.

Solution

- Step 1: The prototype was designed in 3D CAD software and divided into thin layers.

- Step 2: A SLM machine was loaded with die steel powder and a build platform.

- Step 3: The first layer of powder was spread over the build platform by a recoater blade.

- Step 4: The powder was selectively melted and solidified by a laser beam according to the first layer’s cross-section.

- Step 5: The build platform was moved down and the second layer of powder was spread over the first layer by the recoater blade.

- Step 6: The process was repeated for each layer until the prototype was fully formed.

- Step 7: The prototype was taken out of the powder bed and excess supports was removed by laser cutting.

- Step 8: It was machined and hardened to achieve the required finish and properties.