- ŃĆÉIssue AlertŃĆæSite experiencing a technical issue (order lists not displaying), we are working on it!

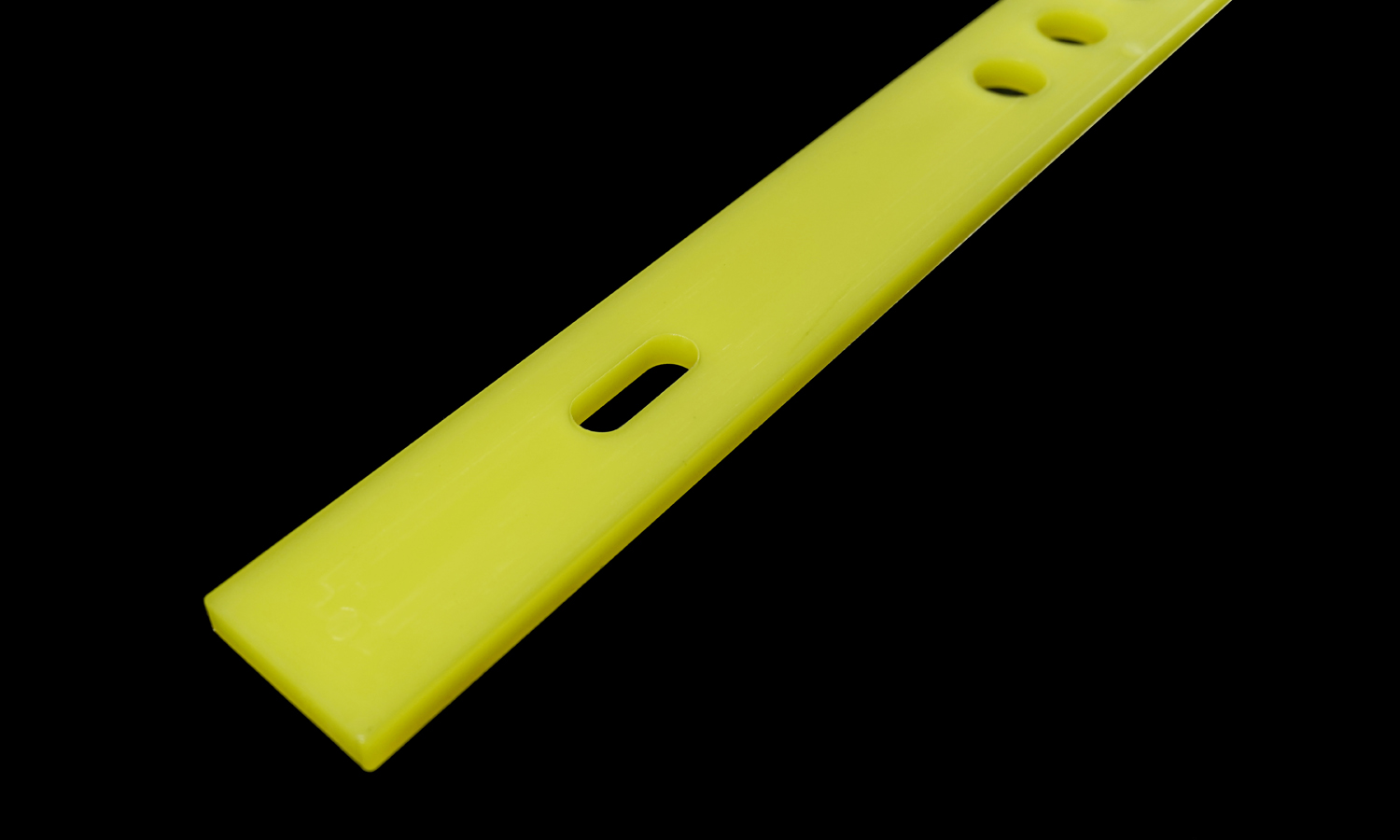

- Compression Molded PU Disc Thick Plain Round Plate

Gallery

About Project

If you are looking for a durable, flexible and versatile material for your next project, you might want to consider┬Ācompression molded polyurethane strip. This is a custom-made product that can be used for various applications, such as sealing, cushioning, shock absorption, vibration damping, abrasion resistance and more.

Polyurethane is a type of elastomer that can be molded into different shapes and sizes by applying heat and pressure. Compression molding is a process that involves placing a preheated polyurethane material into a mold cavity and compressing it until it fills the mold. The material then cools and solidifies, forming the desired product.

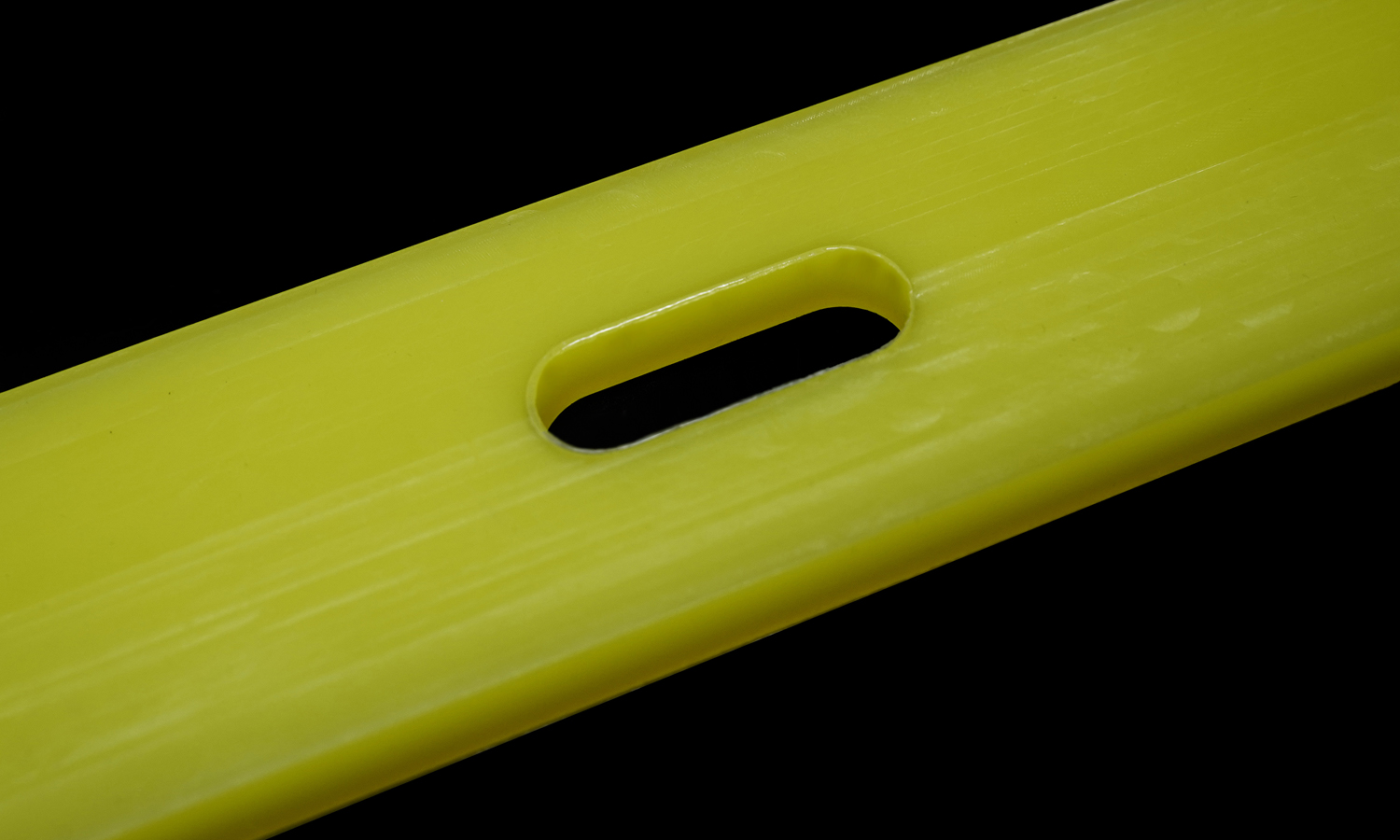

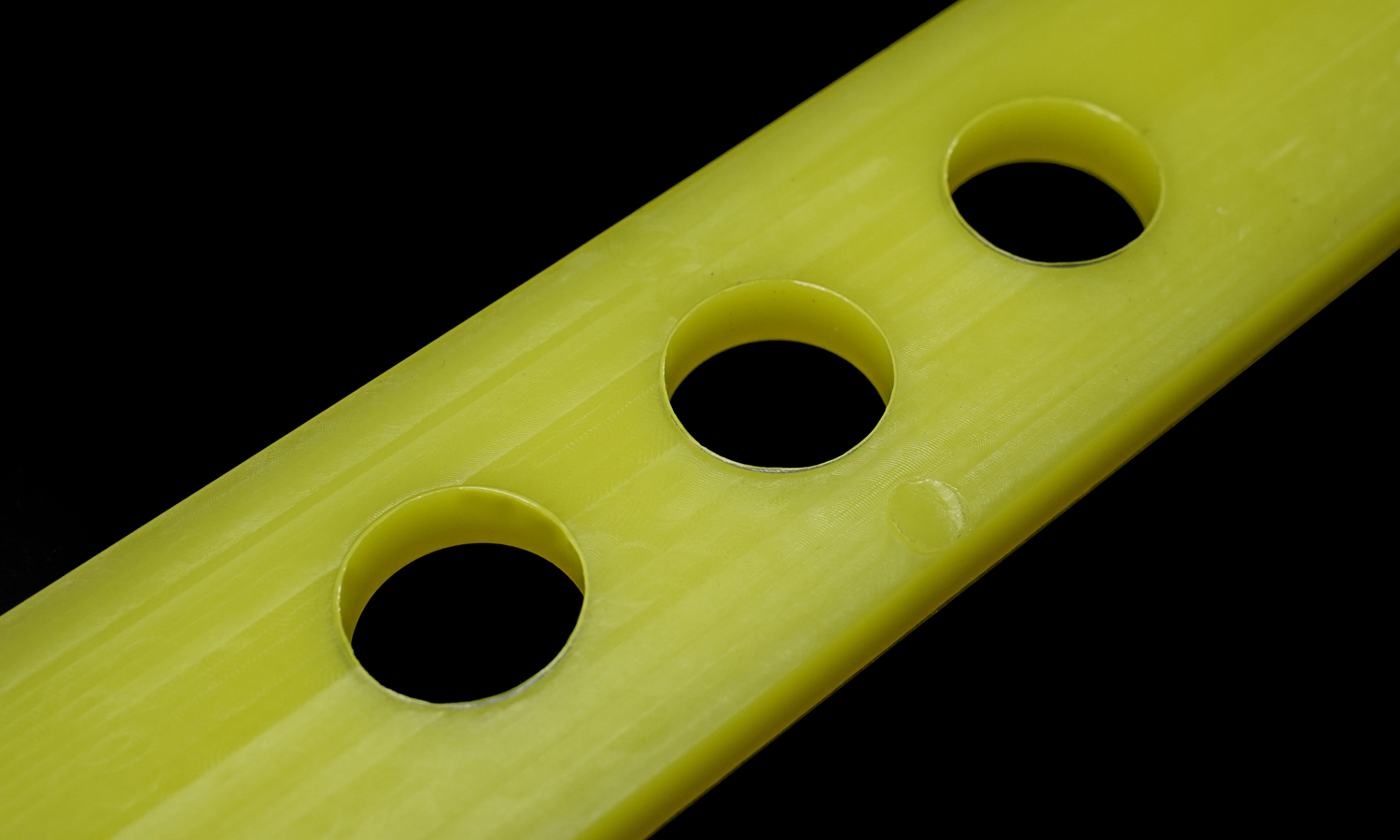

One of the advantages of compression molding is that it can produce complex and intricate designs with high accuracy and consistency. For example, this yellow polyurethane strip has┬Āone rounded rectangle hole, three round holes, and one rounded rectangle hole┬Āfrom left to right, which can be used for attaching or connecting other components. The holes also reduce the weight and material cost of the strip.

Another benefit of compression molding is that it can create products with different colors and finishes. This yellow polyurethane strip has a bright and eye-catching color that can enhance the appearance and visibility of your project. The surface of the strip is smooth and glossy, giving it a professional and high-quality look.

If you are interested in ordering compression molded yellow polyurethane strip with holes, you can contact┬ĀFacFox, a leading pu manufacturing service provider in China. FacFox can offer you competitive prices, fast delivery, and excellent customer service. You can also upload your design files to their online platform and get an instant quote. FacFox can handle any quantity and complexity of your pu molding needs.

To learn more about compression molded yellow polyurethane strip with holes and FacFoxŌĆÖs pu manufacturing services, please visit their website at https://www.facfox.com/. You can also email them at info@facfox.com.

Solution

- Step 1: A yellow polyurethane material, either in the form of granules or preforms, was preheated to a temperature above its melting point.

- Step 2: The heated material was placed into an open mold cavity that had the shape and size of the desired strip.

- Step 3: The mold was closed with a top force or plug member, and pressure was applied to force the material into contact with all mold areas.

- Step 4: The material was kept under heat and pressure until it cured and solidified, forming the strip. The curing time depended on the type and thickness of the material.

- Step 5: The mold was opened and the strip was removed from the mold cavity. Excess material or flash was trimmed off from the edges of the strip.