SLA 3D Printed and Urethane Cast Male and Female Connectors

- A Designer Turned Her Daughter’s Doodles into Toy Bags with SLA 3D Printing

- SLA 3D Printed Resin Statue of a Man with Fairy Wings

Posted on 2021-07-28 in Mechanics В· жңәжў°

Process 3D Print, Support Removal, Post Curing, Urethane Casting, Polish

Material Resin, Rubber

Quantity 5 pcs

Price Range $100-1,000

Lead Time 14 workdays

Material Resin, Rubber

Quantity 5 pcs

Price Range $100-1,000

Lead Time 14 workdays

Gallery

About Project

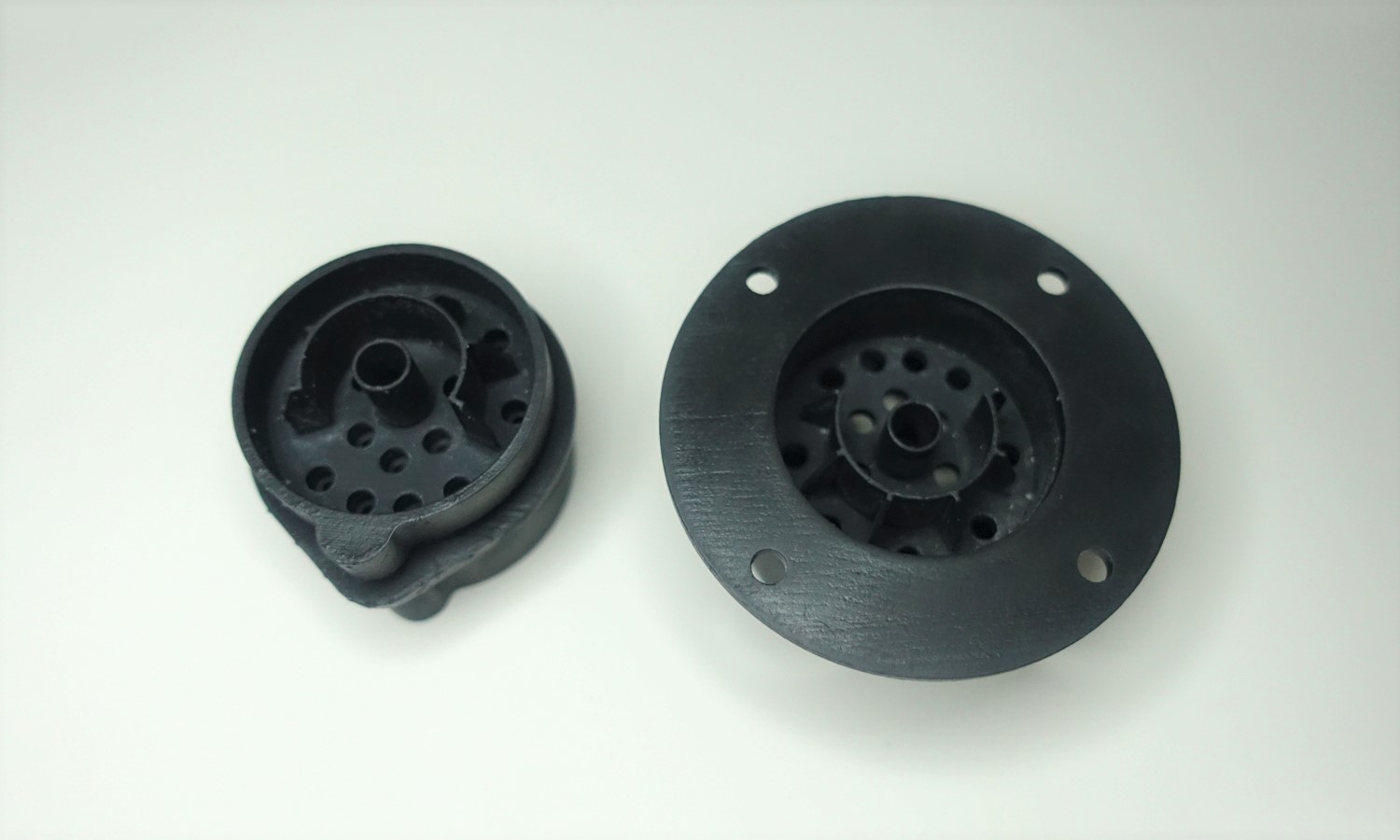

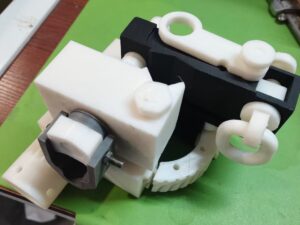

These male and female end-use connectors are made for an enterprise. They are end-use products that will be applied in common temperatures. The client firstly sent us the models and asked for the quotes for 10 sets and 5 sets respectively. After he told us the requirements for all these connectors, we recommended him making some of them with resin and others with silicone rubber. The client accepted the plan and decided to make 5 sets as a trial.

Solution

- Step 1: Examine all the models carefully as they are assembly parts. The models all have thin walls which may break during printing or transportation so we advise the client to revise them.

- Step 2: The device-end connectors are 3D printed with black resin, which has not been added to our materials library. It’s pure black, darker than our SLA Dark Tough Resin, and needs no dyeing process. Then comes regular post-process like post-curing, sanding and polishing. As you can see from the photos, there are many facets inside, it’s a modeling problem because of low resolution and cannot be totally solved with polishing. When printing is finished, we pair all the sets and ensure they can be assembled seamlessly.

- Step 3: 3D print the master patterns of the glass catheter-end connectors with SLA Generic Resin. Then apply the release agent onto the polished master patterns, and encase the patterns with liquid silicone. When the silicone mold is finished, inject the silicone rubber inside and take them out after forming.