3D printer manufacturer WASP will showcase two of its industrial 3D printers at the 2024 Exposanità international healthcare exhibition.

Taking place from 17 to 19 April, the expo will see the Italian company present six medical 3D printing case studies created by its clients. These will include a 3D printed foot model and an anti-gravity brace.

WASP has a long history of utilizing additive manufacturing for healthcare applications. Wasp Med, a multidisciplinary group dedicated to medical 3D printing, was launched back in 2015. In 2018, WASP Med established a Digital Orthopedic Laboratory.

This platform gives patients direct access to custom 3D printed medical support devices, combining the company’s mechanical and technical know-how with the expertise of experienced physicians. According to WASP, the digital library is designed to reduce costs and increase the accessibility of medical care with 3D printing.

Visitors to Exposanità 2024 will find the company’s medical 3D printing showcase in Hall 21, Stand C78 at the BolognaFiere exhibition center.

WASP 3D printing at Exposanità 2024

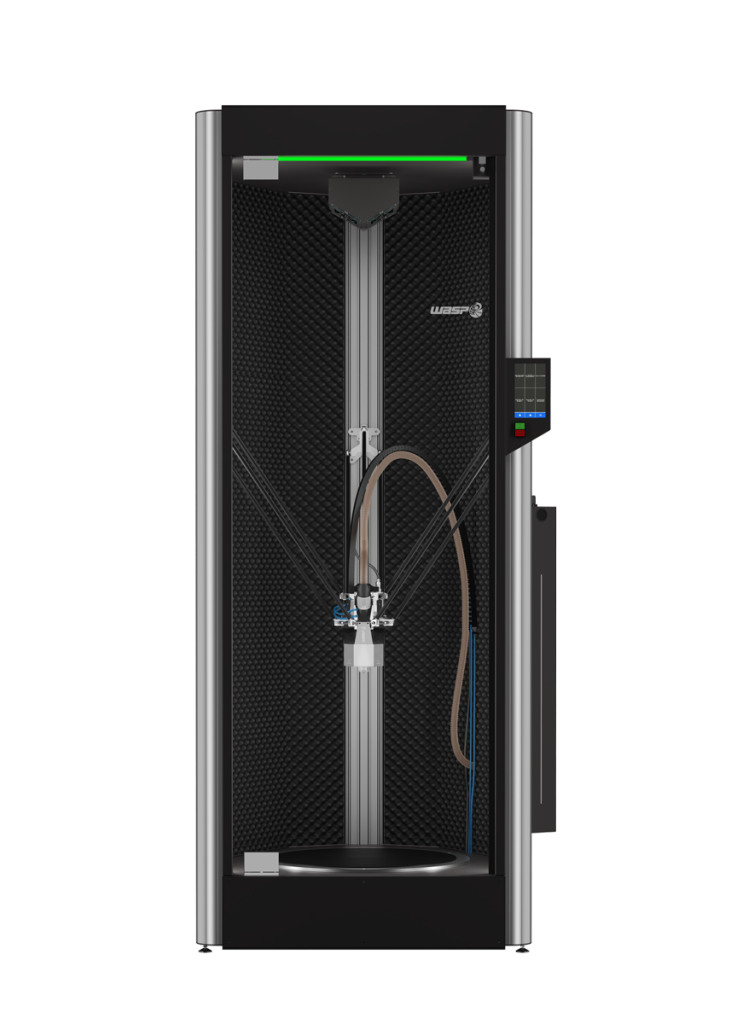

The firm’s WASP 4070 FX and WASP 60100 HDP industrial 3D printers will be on show at the Bologna-based event. The former is designed to offer high precision when 3D printing with flexible filaments like TPU, TPE, and PP. These materials are common in medical applications such as prosthetics and wearable medical devices.

The WASP 60100 HDP is a large-format 3D printer with a build volume of Ø 600 mm x 1000 mm. This system is capable of 3D printing with thermoplastic pellets, allowing it to produce both flexible and rigid parts.

In particular, the 60100 HDP is compatible with pelletized ASA, PP, TPU, PEEK, and PC. According to WASP, the 3D printer’s pellet extruder reduces material costs by up to 90% compared to the corresponding filaments.

Alongside these two 3D printers, Exposanità 2024 will see WASP showcase a variety of 3D printed medical devices produced with the company’s technology. One such application is a foot prosthetic produced by prostheses specialist Procosil on the Delta WASP 4070 PRO and Delta WASP 2040 FDM 3D printers. The foot was fabricated using FiloAlfa’s AlfaPro PLA and Filaflex 95A TPU from Recreus.

A modular postural unit 3D printed in PETG using the WASP 470 FX will also be on show. Called Koala, this postural unit is designed for children from the age of four months to four years and was manufactured by Barbieri spa – Progettiamo Autonomia.

Also 3D printed with the 4070 FX is an anti-gravity brace by orthopedics company Ortopedia 3D. Developed by Martina Leoncini and Francesco Ciriello, this brace is made from polypropylene (PP) which has been certified for medical use. Additionally, Visitors will be able to see a 4070 FX PP 3D printed leg brace, produced by Ortopedia Pessina.

Manufacturing on Demand

Another 3D printed medical device being showcased is a Transtibial Socket Fitting for prosthetic limbs. Produced by Italian prosthetics company Centro Protesi INAIL, this part was 3D printed in Nylon Carbon using the WASP 4070 ZX.

Finally, for those wanting to see the capabilities of the 60100 HDP, WASP will also be showcasing a 3D printed orthopedic seat produced using TPE pellet material.

3D printing for medical applications

3D printing is being increasingly adopted for the production of customized medical devices such as prostheses and orthopedic implants.

Earlier this year, UK-based robotics company Open Bionics announced that its 3D printed fingers had been adopted for the first time by a hand amputee from London. Called the Hero Gauntlet, this 3D printed prosthesis can be customized to individual user needs and enables those with congenital and acquired partial hand limb differences to regain hand functionality.

Elsewhere, 3D printer manufacturer 3D Systems has used its point-of-care additive manufacturing offering to create a patient-specific 3D printed cranial implant for a procedure at the University Hospital Basel. This was said to be the first cranial implant 3D printed at the point of care that complied with current Medical Devices Regulations (MDR). The biocompatible implant was fabricated on the hospital’s 3D Systems’ EXT 220 MED extrusion platform using polyetheretherketone (PEEK) material.

Similarly, Salzburg University Hospital has also seen success with 3D Systems’ point-of-care 3D printing technology. Under the guidance of Dr. Neha Sharma, Ph.D., in-house clinicians created 3D models from a 55-year-old craniosynostosis patient. These were used to design and 3D print a personalized occipital prosthesis. The hospital’s Department of Neurosurgery also 3D printed patient-specific post-decompressive craniectomy implants.

You might also like:

Researchers 3D print new ultra-realistic heart and lung models that can bleed, beat, and breath: Designed for organ transplant training, the lifelike models reportedly reflect the tactile qualities of a human heart and can be produced with various tissue hardness levels. Using the models, medical professionals can plan surgeries and safely research and teach transplant procedures, without the risk of complications.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Alex Tyrer-Jones

Leave A Comment