On the topic of AM automation, London-based Ai Build needs no introduction. The company, which has brought to market a large-scale robotic 3D printing platform, was founded with the express goal of solving automation-related challenges associated with additive manufacturing through its AiSync software platform.

Many across AM will be familiar with Ai Build for impressive collaborations within the architecture and design worlds—including an amazing 57-square-meter pavilion at the Venice Biennale in 2018—but Ai Build is a technology company at its core, one with goals to continually advance and adapt to the market and its needs. In the following interview with Ai Build Co-Founder Daghan Cam, we learn about the company’s automation mission with an increasing focus on industrial sectors like aerospace and automotive, as well as its AiSync software that automates large-scale additive manufacturing.

Ai Build…ing something new

Ai Build was founded in 2015 by Daghan Cam and Michail Desyllas, two innovative minds with backgrounds in architecture.

“We could see a big potential for additive manufacturing in various industrial applications,” Cam tells us. “But at the same time, we were frustrated with the fact that the technology didn’t scale up well for the applications we wanted, like architecture and construction. Every minor problem in traditional desktop size 3D printing is multiplied in large-format AM by a factor of 10 or more, making the entire process from design to finished part extremely hard. That’s why not many people have even considered 3D printing at such large scales until recently.

“Our starting point was to investigate what makes AM, particularly in large format, so inaccessible. It didn’t take long to understand that the lack of automation was the biggest barrier, by far. We were seeing days or even weeks of manual toolpath engineering attempts for fabricability of parts and failure rates were about 40 to 60 percent, which was totally unacceptable. We broke down the process to understand where exactly the lack of automation was coming from. We looked at what happens before printing begins: how users are optimizing their designs, how process parameters are selected and how designs are processed through slicing software. At the time, these steps were very much based on the process knowledge of machine operators combined with lots of trial and error. We thought there could be a better way to do it, an automated way to achieve consistent results with additive.” That, Cam says, is how he and Desyllas came up with the AiSync platform for autonomous large scale 3D printing.

Ai Build’s solution

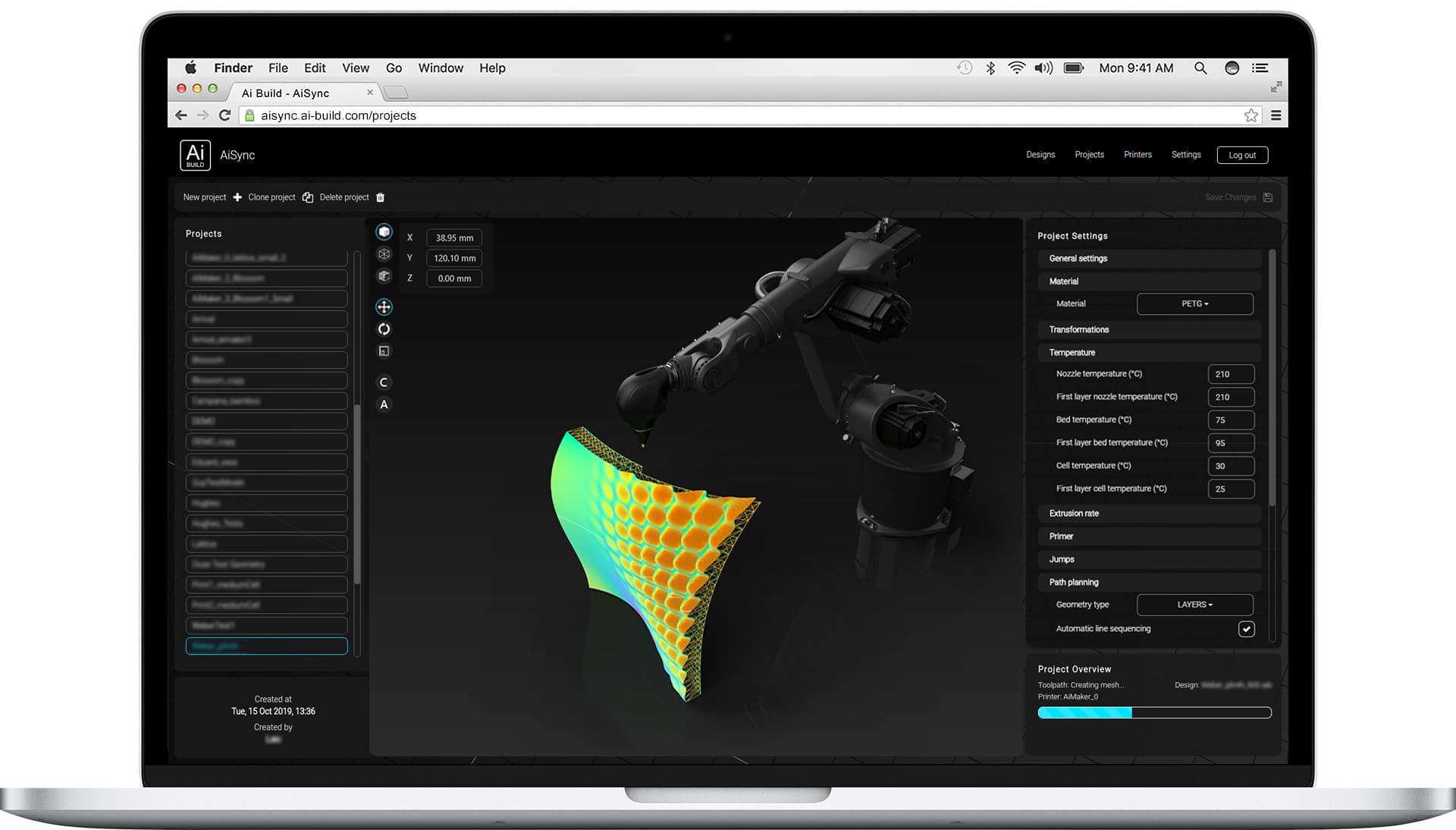

Ai Build’s solution to large-scale additive manufacturing consists of a few components: the AiSync software, an FFF/FGF based polymer extrusion system, an optional enclosure for environmental control and a robotic arm. This multi-component configuration allows the company to develop large-scale 3D printing features for a wide range of hardware solutions. At the core of Ai Build’s recommended hardware setup is an industrial robotic arm from KUKA, a manufacturer of industrial robots and solutions for factory automation, with UK headquarters in Wednesbury, West Midlands.

Cam explains: “We needed a very robust actuator that should be fully reliable and never fail. In order to achieve that 100% guarantee of success with the hardware, we partnered with KUKA, as official system partners, who are very well known for high precision and highly reliable industrial robotic arms.”

The second key component on the hardware side is the AiMaker, the company’s own extrusion system, capable of extruding thermoplastics and composites at a rapid rate of 3 kg per hour. “Developing an autonomous 3D printing technology is like developing an autonomous car. You cannot build a self-driving software and install it on any car in your backyard. The hardware needs to support the software with specific performance, sensors, cameras and computers.”

Cam says of choosing to develop a new extrusion system for large-format AM: “The existing extruders on the desktop 3D printing market were too slow, too unreliable, and they didn’t have the electronic components required for real-time control. So we built the AiMaker from scratch, which is to date the world’s fastest FFF extruder on the market. Luckily, this gap for commercially available hardware components for large format AM has been filled in the last couple of years. Several European and American OEMs have released powerful large-scale 3D printers and today there is a healthy number of hardware options to choose from in this new and fast-growing AM category.”

All hardware components that are compatible with Ai Build’s autonomous large-scale 3D printing technology, are equipped with an array of sensors, cameras and computers which communicate with the AiSync software.

AiSync: the key to the puzzle

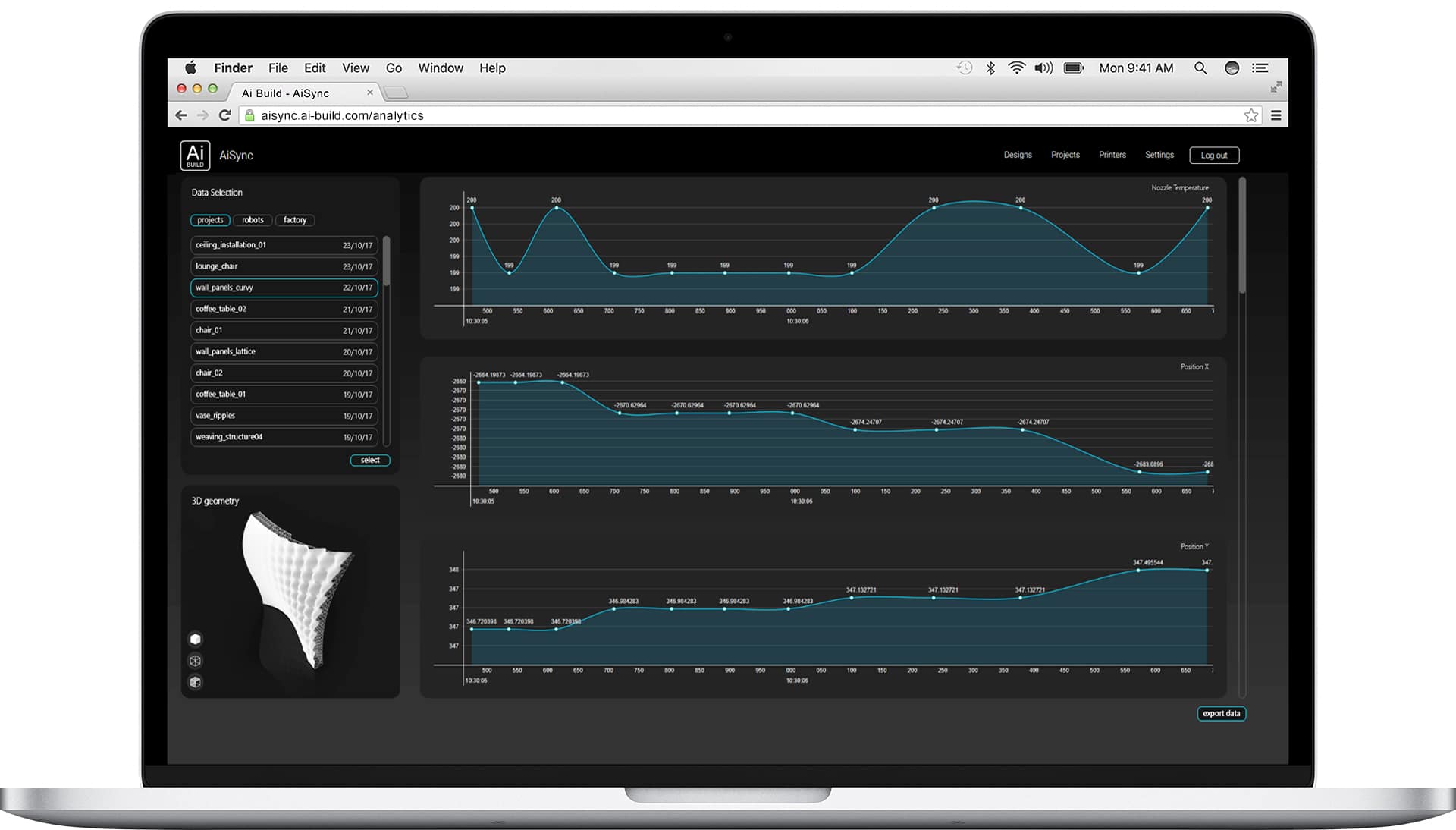

AiSync, in the simplest terms, is a cloud-based software that takes design files and generates optimized machine instructions for large-scale 3D printing automatically. The software makes additive manufacturing of large components such as molds, jigs, fixtures and end-use parts as easy as clicking a few buttons on a web platform.

Manufacturing on Demand

“The first thing that sets AiSync apart from conventional 3D printing software packages is that it takes full advantage of the additional degrees of freedom that come with the robotic arms,” Cam says.

“3D printing typically works in a linear layer-by-layer fashion, so by moving the extruder in three dimensional space without constraining ourselves to flat layers, we can produce very efficient structures in much shorter timeframes and in higher quality. AiSync’s multi-axis motion planning features allow our users to achieve structurally optimized 3D infills, non-planar slicing and even non-planar hybrid additive-subtractive treatment of surfaces with minimal effort.

“With additional degrees of freedom, however, comes the challenge of toolpath design and optimization, because there are almost infinite ways to create a path in three-dimensional search space. AiSync uses analysis and simulation tools with high computing power on the cloud to determine the optimal toolpath for a given project within seconds, eliminating the need for excessive human labor and time-consuming trial and error.”

In addition to automating this part of the additive manufacturing preparation, AiSync also plays an important role during the printing process. “The second aspect of the software that increases the level of automation dramatically is real-time communication with robots,” Cam continues. “Most 3D printers on the market take a G-code file and blindly execute it without having any control over that process, which is the exact opposite of autonomous manufacturing. Essentially, if anything unexpected happens, the process will fail, which is highly likely in large-scale AM. For this reason, we abandoned G-code and developed a completely new machine control process from scratch that is resilient to environmental, material and hardware-related inconsistencies.” The robots are driven by AiSync exchange data with a computer bi-directionally in real-time. Ai Build refers to this edge device as the AiSync Printer-Server which gives the ability to detect and compensate for common problems on the fly, with significant savings on time and materials.

“As a result of AiSync’s powerful simulation and optimization capabilities, our users achieve high quality production parts in short amounts of time without even noticing the difficulties associated with large-scale additive manufacturing.”

Opening up AiSync

One of Ai Build’s latest (and very exciting) announcements is that it is working to open up its technology to other manufacturing companies. Cam says: “Initially AiSync was developed for the AiMaker, but more recently, we started integrating it with other industrial 3D printers. We have already partnered with several hardware manufacturers and that is keeping us very busy these days.” At the moment, these integrations will be focused on other large-scale multi-axis 3D printers, though Cam says most of its processes can also be used for gantry 3D printing systems.

“We have announced our first partnership on AiSync with Weber Additive, a German manufacturer of industrial 3D printers with more than 100 years of experience in machine development and manufacturing” Cam reveals. “By combining the advanced control and monitoring features of AiSync with powerful industrial machines built by Weber, we are bringing to market highly automated and robust large-scale additive manufacturing solutions for heavy industrial applications.”

Cam exclusively anticipates that the company will soon be unveiling the first AiSync powered Weber machine—a multi-axis large-scale 3D printer including a Kuka robot and a Weber AE020 pellet extrusion system. “This partnership allows us to scale our operations in key industrial markets such as automotive and aerospace,” he says.

Envisioning the future

Down the line, Cam has a clear vision for how the Factory of the Future could play out, one in which automation drives lights-out production and additive is the key manufacturing process. “The advantages of additive are quite obvious to us: it’s the most material-efficient way to do things, and it’s also very capital efficient: you don’t need expensive tooling,” he states.

“What became very clear with COVID-19 is that AM is also the most efficient technology for the supply chain,” he continues. “It eliminates transportation and storage because everything is done on demand. The biggest obstacle holding back the technology right now is the lack of automation. At Ai Build we are constantly asking ourselves what needs to change to achieve higher levels of automation and we are working closely with our industrial partners to accelerate our move towards autonomous lights-out manufacturing.

“One key technology that needs to be embraced by manufacturers to increase automation is cloud connectivity. Before COVID-19, highly regulated industries like aerospace were concerned about storing their data on the cloud, but now that is loosening up a bit with the increasing desire for automation. Cloud, when done correctly, can be more secure than on-premise solutions. This is already proven in other services like CRM platforms and accounting software that became almost entirely cloud-based in the last few years. Our mission at Ai Build is to enable the factories of the future that are autonomous, cloud-connected and primarily additive. There is of course a lot to do, but we are moving rapidly in that direction.”

*This article first appeared in 3dpbm‘s AM Focus eBook on Automation. Read the entire issue here.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Tess Boissonneault

Leave A Comment