Richard Elaver’s interest in design began in the 1920s, following the Grateful Dead in the mid-1990s. He dropped out of college and wandered for the next few years – hitchhiking, driving a taxi, working on a farm, and living in a yoga center. He grabbed a skill from books and sold hand-wrapped crystals at concerts.

Nearly 30 years later, Appalachian State University professor Elaver is still making jewelry as well as decorative and functional artworks. As his experience grew, his approach as a designer and craftsman changed, and now he integrates technology, model building, and computer numerical control (CNC) equipment into his work.

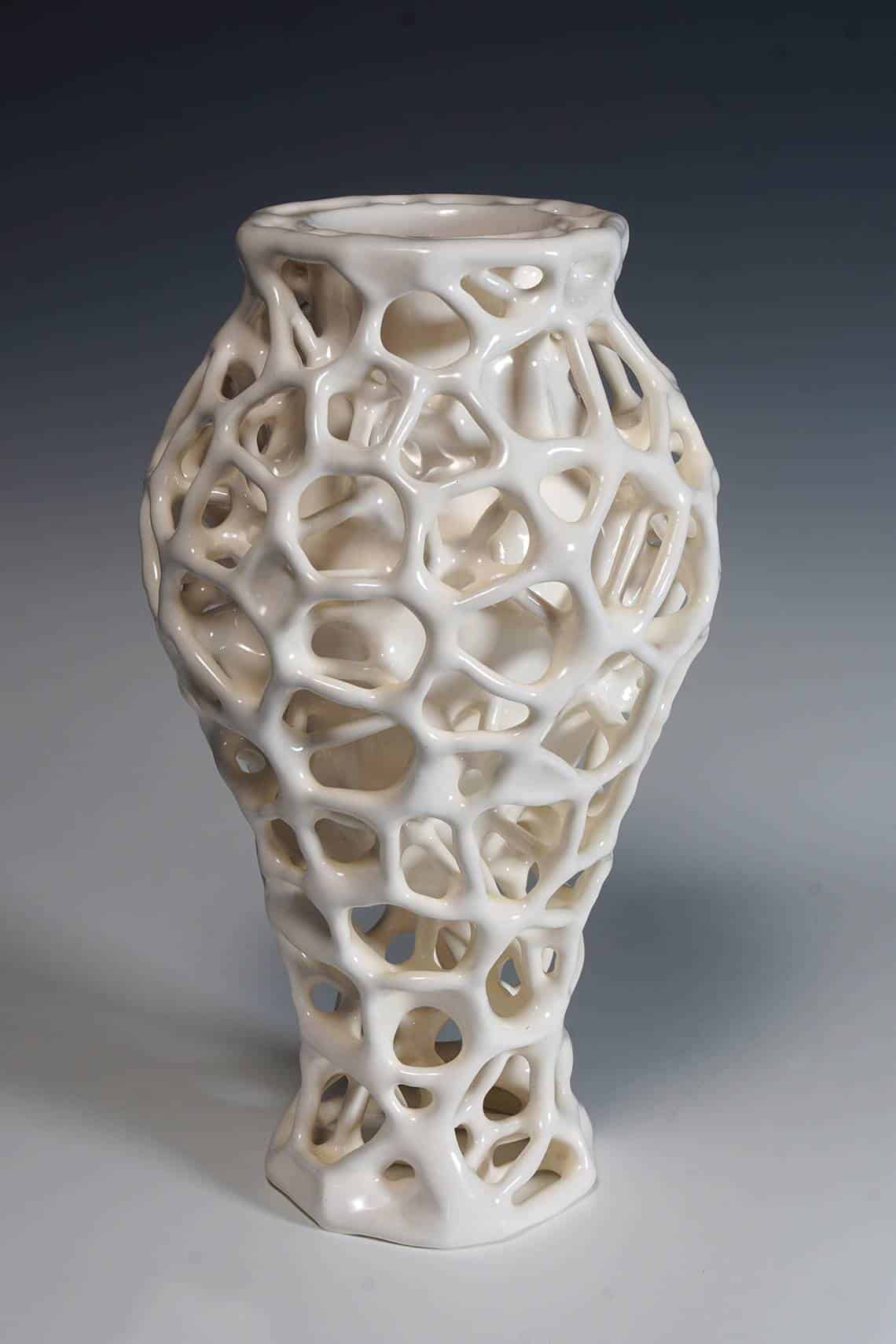

His solo exhibition “Structure and Void” was exhibited in the Overcash Gallery of the main campus of Central Piedmont Community College before March 12. Thirty works were exhibited, such as 3D printed bowls, jewelry, lamps, and so on. The exhibition also included Elaver’s “Pod Earrings,” “Wripple” wall hangings, and “Dissolving Tiffany” vases.

One of A Kind

The obsession with finding ways to use his technological background and product design knowledge to create large-scale personalization has driven Elaver’s practice. His thesis for the Master of Fine Arts: He wrote three programs to create a set of silverware without utensils.

47-year-old Elaver said: “In the product world, you are always making thousands of the same things. The game is how you use this function with all its precision, all controls, and all materials and processes to make one-of-a-kind objects?”

During the spring break last year, he completed his new episode “Dissolve Tiffany” at Appalachian State University. He studied Grasshopper, a generative software program used to create complex models. It is particularly helpful for randomization.

“I’ve been trying to figure out how you take something that’s a 3D print and make it into a more luxurious object,” he said. “Instead of it having this crude grainy surface to it, how do you make it sleek and smooth and desirable or aesthetically pleasing? It’s something that’s been a challenge for me ever since I started 3D printing.”

Inspired by Nature

Elaver’s process begins with a sketch. He provided the information to CAD (3D modeling software) and exported the form to the CNC machine. He writes code to construct objects that are different each time the program runs.

The cell morphology in nature inspired him, and it was obvious in his works. Materials such as nylon, gypsum, and plastic are sometimes manually coated with resin or epoxy resin, depending on his appearance requirements. He also used wood, acrylic, and paper for other projects.

“I was using that process to make a series of earrings,” he said. “No two earrings are exactly the same. I would run the same program, but every time it was run, it would give (me) another shape. I used that to design a number of things – from jewelry to furniture to functional objects like bowls and vases.”

A Product Designer

Elaver grew up in Stoughton, Wisconsin. After staying there, he studied the master goldsmith in Stoughton from 1994 to 1999. When he decided to become a jeweler but wanted formal education, he began studying art history and sculpture courses at the University of Wisconsin-Madison. He obtained a degree in metal processing in 2001.

“My goal was never to get a degree,” he said. “It was to become a professional craftsman. But I really liked it. I really got hooked on the academic side of art.”

After graduation, he worked as a product designer at Design Concepts in Madison for three years. He designed lawn mowers, catcher masks, and medical equipment for companies such as Harley-Davidson, Honda, and Polaris. But the idea of outdated plans and mass production surfaced.

“I had become disenchanted with the feeling that I was producing next year’s garbage,” he said. “My conscience got the better of me. (I was) missing the fine art world and craving to do my own work.”

Combination of Art & Technology

In 2003, he was admitted to the Cranbrook Academy of Art in Michigan, where he studied industrial design and metal for two years. He began to combine technical and industrial design with art.

His first project was to make glasses using a desktop CNC machine. He asked himself, “How can I make custom, high-end eyewear using industrial tools?”

His answer was a spectacle frame made of Buffalo horns and golden hinges. From an industrial design perspective, he combined the jeweler’s attention to detail with the machine’s production capacity. This summer, he taught this technique at Penland Craft School’s “Making Wonders”.

“I really like the concept from manual to mechanical to mechanical,” Elaver said.

After graduating from Cranbrook, Elaver joined the Fulbright Program to travel to Amsterdam to collaborate with concept design company Droog. He designed exhibitions for them.

After completing the one-year course, he taught for four years at the Purdue University Fort Wayne Visual Arts course. Nine years ago, he moved to Boone to work as an associate professor at ASU. Now he teaches design basics, modeling software, product design, and advanced apex studio.