The pavilion is designed in the Great Northern Way, with florid wood, steel and glass structures designed by Perkins and Will and Canadian timber experts Spearhead, anchoring a new public plaza near Bella Vancouver, British Columbia. The 2,000-square-foot space, completed in 2019, will be the location of a coffee shop, adjacent to the South Flatz office building designed by Perkins and Will, and the new campus of Emily Carr University of Art and Design.

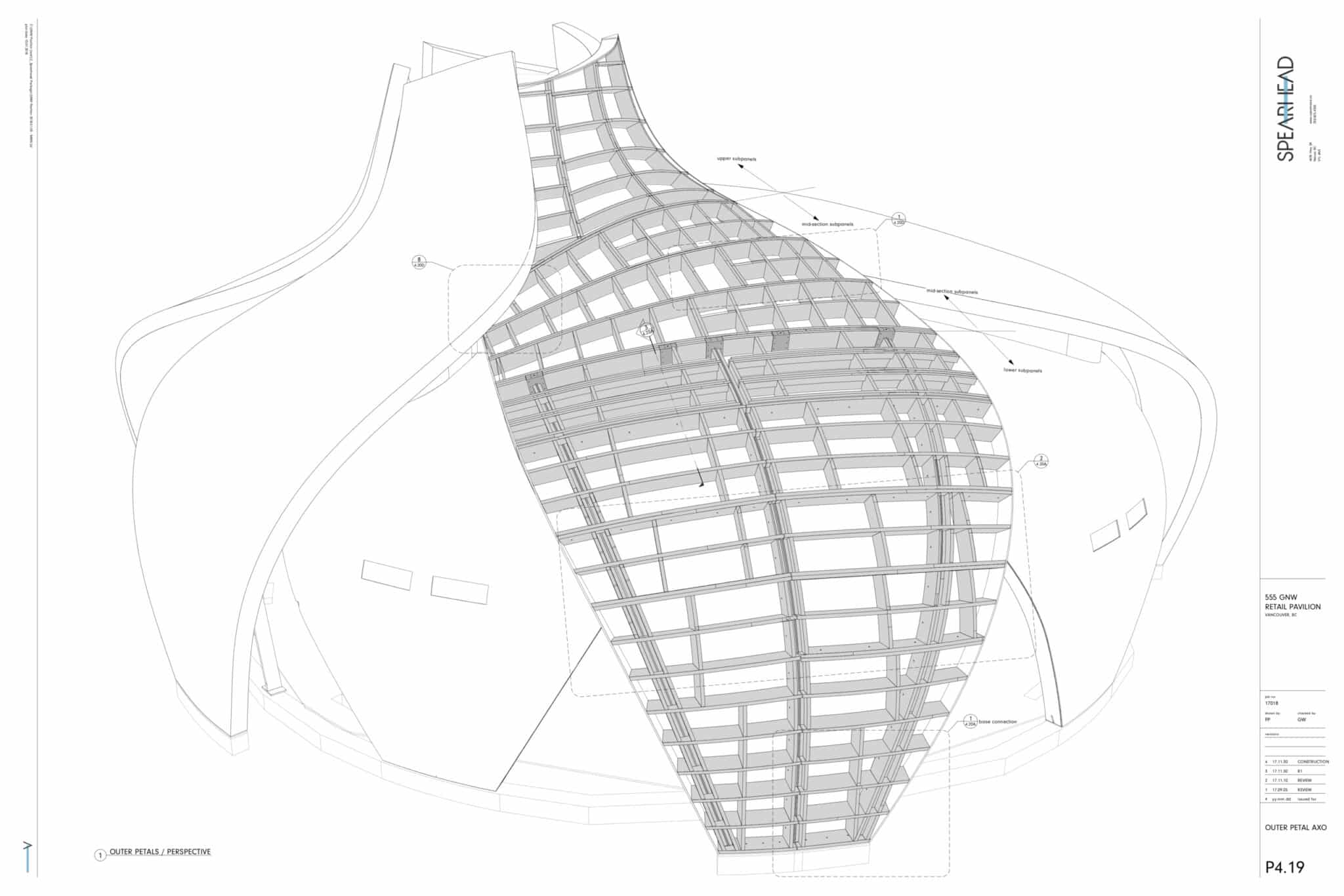

The main elements of the pavilion are ten overlapping curved “petals” covered with bright red aluminum composite tiles. The petals are 30 feet high and frame the central glass eye. Initially, the architects tried to achieve the flow form by nail-laminated wood planks (stacked-size wood fixed with nails) formed by 5-axis CNC carving. However, the budget for this method is only 1.4 million US dollars, so the cost is too high. Instead, Spearhead has developed a waffle frame model, which is carved from economically laminated stranded wood and glued wood, and sculpted with a 3-axis CNC machine. This method greatly reduces the need for the exhibition hall. The number of materials and promote the direct installation of insulation materials and MEP infrastructure.

Simplifying the broad outline of the pavilion does not reduce the complexity of the project’s mixed parts kit. The shear wall system is composed of curved steel plates reinforced with glulam on both sides, while the slender profile of the upper layer depends on the steel plate steel columns cut by CNC. These columns are laterally supported by engineering wood members. The roof partition and the shear wall system are wrapped in plywood; the moment of extreme curvature is covered by a thin layer of plywood laminated together. The narrow strips of birch plywood are applied to the inside and overlap into curved wall panels. In total, there are approximately 6,950 customized CNC-cut wood parts, 875 customized CNC structural steel parts, and 1,350 Simpson brackets.

Blackcomb Facade Technology, a frequent collaborator of Spearhead, has special expertise in complex assembly and hybrid structures, using the RAICO Therm + AI system with Guardian SunGuard glass to process the five curved glass compartments of the pavilion.