The US-based Pikus Concrete has partnered with Sika to commercialize 3D concrete printing technology in the construction industry and tap its huge potential. Pikus’ first 3D concrete printer using Sika technology has already begun operations in Lehi, Utah. The company is working hard to implement the technology in the first construction project. This marks the first time that a construction 3D printing transaction has involved two mature commercial construction companies. Previous projects usually involved at least one startup or government investment entity.

Sika has decades of complete expertise in the digitalization and industrialization of concrete buildings, and its 3D printing technology has been integrated. Expertise includes robotic technology, process control systems, and extrusion systems, then concrete technology, as well as 3D mortar mixing design and formulation, which can accurately control the behavior of concrete. Sika is the only company that can provide all the technologies needed for industrial 3D concrete printing in one stop.

Speed up construction

A key advantage that Pikus sees is the increased speed of project construction, because there is no longer a need to build and remove templates. “We will be able to print out our structural elements before work begins and ship them to the site when needed. Rob Pikus, owner of Pikus Concrete, said that depending on the complexity of the structural elements, this can save months of construction time, And can save greater costs.

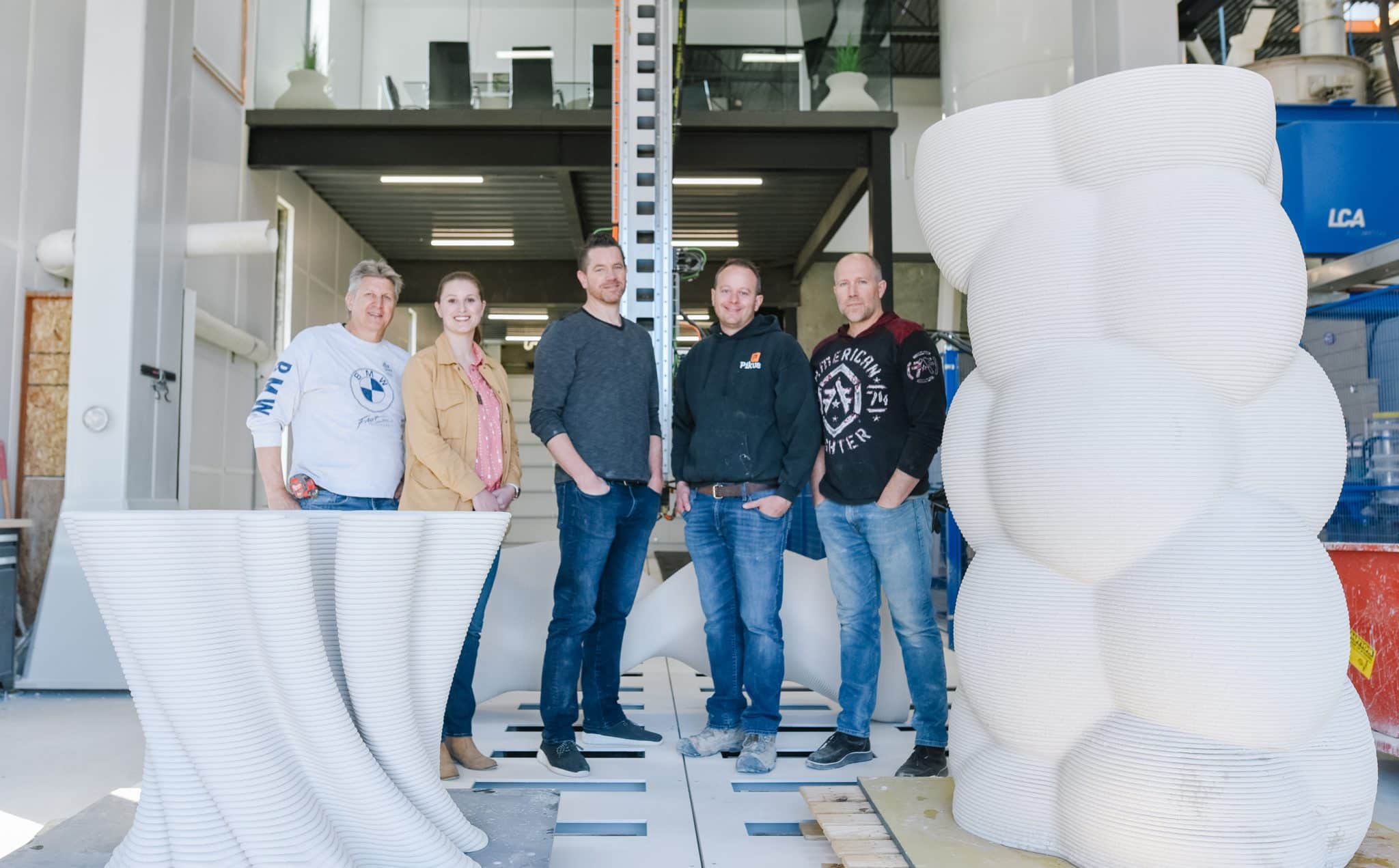

Pikus is convinced of the technology and its market potential. “Currently, we have invested more than $3 million in this project. This includes a new building that can accommodate large 3D printers, actual printers, and the labor required to start the process.” Pikus plans to invest heavily in the next few years Its goal of owning 20 printers in the United States by mid-2024.

Wide range of applications

“We conducted a lot of research to find the best 3D concrete printing technology. During our European tour, we met with Sika’s experts, who explained their technology and showed us an impressive live demonstration of the printer. “This is indeed a turning point for Pikus. He concluded: “We know that we need Sika’s expertise to put this process into practice.”

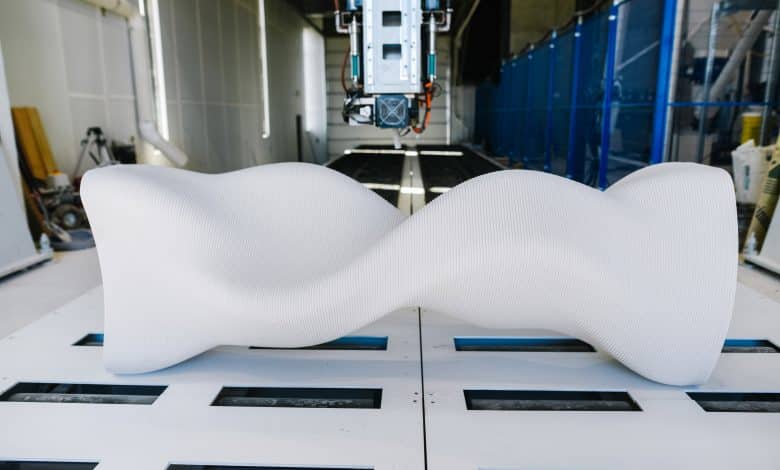

3D concrete printing enables architects to achieve the most challenging shapes. Dynamic curves and future interconnected structures can be printed efficiently from the digital plan. Pikus’ current strategy is to define the areas where 3D printing will be most beneficial to the industry. Rob Pikus: “We see a huge opportunity to print difficult or expensive items. This will help bridge the gap between architectural and structural elements.”