A team of researchers from Zhejiang University of Technology, Tianjin University, Nanjing University of Science and Technology, and Ritsumeikan University have used 3D printing to create soft robot fingers.

Driven by an embedded single-electrode triboelectric curvature sensor (S-TECS), the addition finger can induce bending curvature at ultra-low operating frequencies without the need for an external power supply. The production of this device is a proof of concept that multi-material 3D printing can be used not only to manufacture soft actuators, but also to manufacture functional sensors. The researchers hope that this innovation will pave the way for a simple, fast manufacturing process to produce controllable soft robots.

A unique method of constructing mechanical fingers

Robot technology constructed with a mixture of soft materials and compliant structures is increasingly providing solutions to the challenges posed by the aging population. With the development of soft robot research and the development of new manufacturing methods, human-computer interaction has become more and more secure, and opened up new applications for the technology. Now, for example, it is possible to directly print soft robots with airtight complex structures and hard components. This development has brought innovations such as the 3D printed jumping robot produced by Wyss Institute in 2015.

Other software robot projects, such as the Wyss team’s project, have integrated software sensors based on piezoelectric, conductive, magnetic, and organic optical materials into their software robot designs. However, according to the researchers, these sensors may have disadvantages such as long prototyping time, unstable cable connections, complicated system assembly, and difficult system integration.

As a result, the research team chose to use triboelectric sensors. This type of component provides high stretchability and sensitivity, so that the robot can actively sense and sense its deformation or response in real-time. The use of 3D printing in this process also enabled the team to use multiple materials and utilize a one-step printing process that shortened the prototyping time. The researchers’ S-TECS sensor is constructed by combining a triboelectric curvature sensor and a retractable electrode, avoiding the same integration complexity as the previous project.

Integrate S-TECS sensors into 3D printed parts

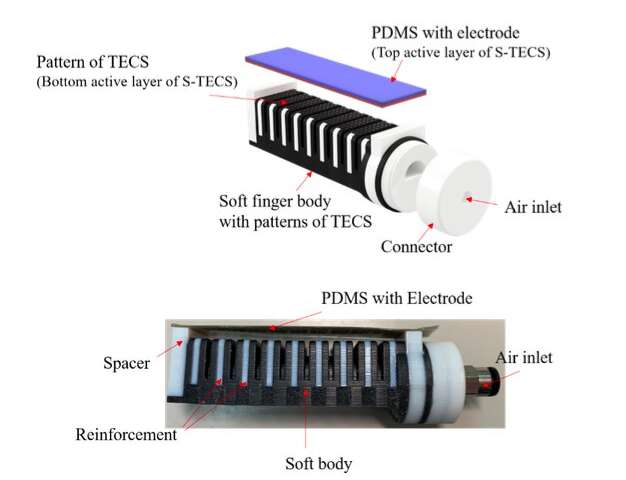

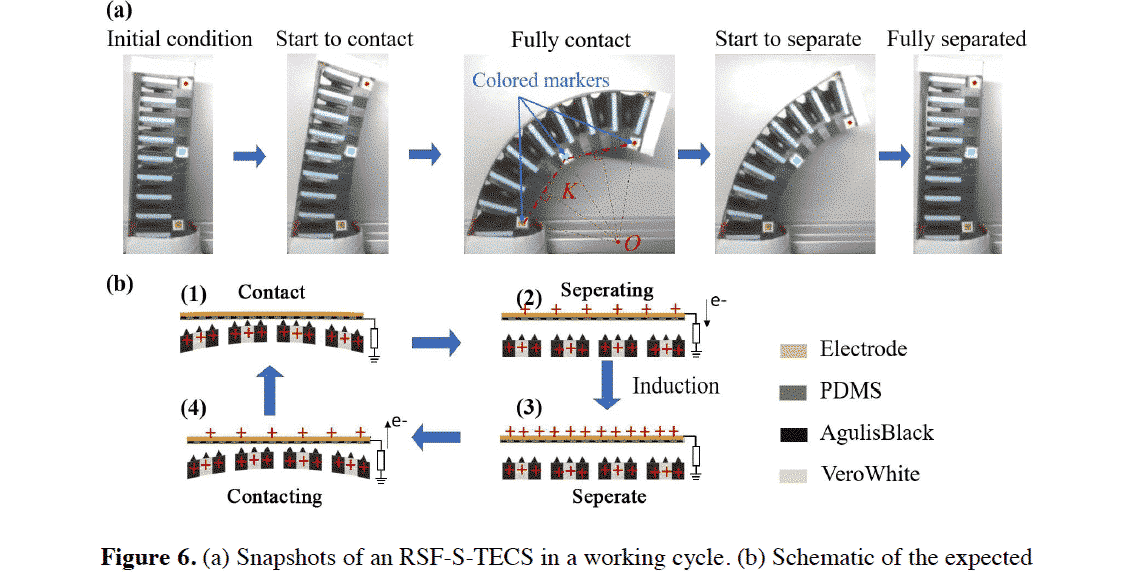

The main body of the device is composed of nine inflation chambers connected to the main airway, each of which is rectangular to provide a flat surface for printing S-TECS patterns. The width of the hard-reinforced chamber is 2 mm, with two shims at both ends to support the top layer of S-TECS and maintain a height of 3 mm between the two layers. The additional finger can only be bent in one direction according to its chamber configuration. When the finger is bent, the top layer of S-TECS begins to approach the bottom layer until it is completely in contact, activating the contacts to charge and generate electricity.

The device was produced in two parts using the Stratasys multi-material Objet350 3D printer: an enhanced soft body and connector. The pattern of S-TECS is printed directly on the top surface of the finger body to simplify the entire manufacturing process and reduce production time. The triboelectric layer and the flexible body of the device were produced using a friction-like AgilusBlack printing material because its tensile strength was 2.75 MPa and the elongation at break was 250%. The curing is performed at room temperature for 24 hours, and then the 3D printed parts of the fingers are screwed together, and the S-TECS is pasted through the silicone adhesive to complete the assembly.

The researchers tested the performance of the sensor under different conditions by changing the surface structure, the force exerted on it, and then automatically set operating frequency. It has not been found that integrating sensors with different soft materials will reduce the flexibility and adaptability of the entire robot system. In addition, these sensors have been proven to measure finger curvature up to 8.2 m-1 at ultra-low operating frequencies of 0.06 Hz.

The test not only proved the effectiveness of S-TECS as a self-powered curvature sensor, but also proved the feasibility of using multi-material 3-D printing technology to create a flexible robot structure with a triboelectric layer. The researchers concluded that this method may be used in future robot applications that use advanced sensing capabilities.

Additive manufacturing and soft robots

3D printing has been used to create soft robots with a wide range of applications from the aerospace industry to medical uses.

A 3D printed soft robot muscle developed by Cornell University, a scientist from New York, is capable of controlling its internal temperature by sweating in January 2020. The finger-shaped soft actuator can keep moisture and respond to the temperature itself by cooling down.

A pair of NASA researchers successfully produced a flexible robotic actuator using 3D printing technology in May 2019, which is a key component for animating and controlling the robot’s moving parts. This research is part of a broader study of potential soft robot applications in space.

Researchers from Rutgers University-New Brunswick University created a new hydrogel 3D printing material in May 2018. This material is very flexible and can walk like a human. The material was developed specifically for the medical industry and can be used to deliver drugs to targeted parts of the body, thereby reducing the risk of harming patients.

The researchers’ findings are described in detail in their title entitled “Soft Robot Fingers with Self-Powered Triboelectric Curvature Sensors Based on Multi-Material 3D Printing”. The research was published in the “Direct Journal of Science” and was co-authored by Zhu Mingzhu, Xie Mengying, Lu Xuanming, Okada Shima, and Kada Masao.