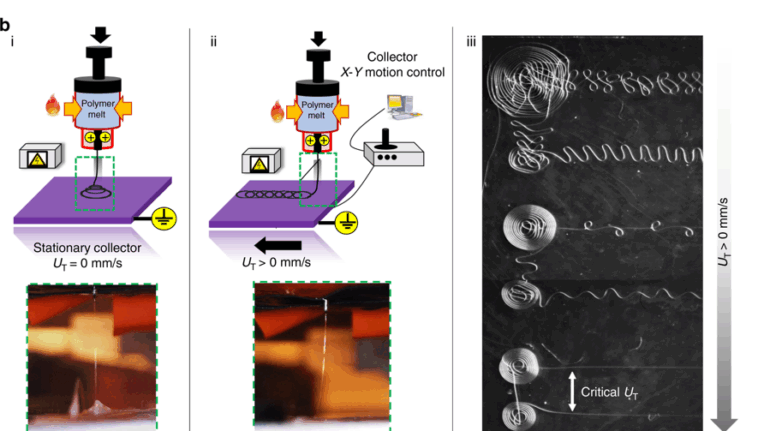

Triastek Collaborates with Lilly on 3D Printing for Oral Delivery of Drugs

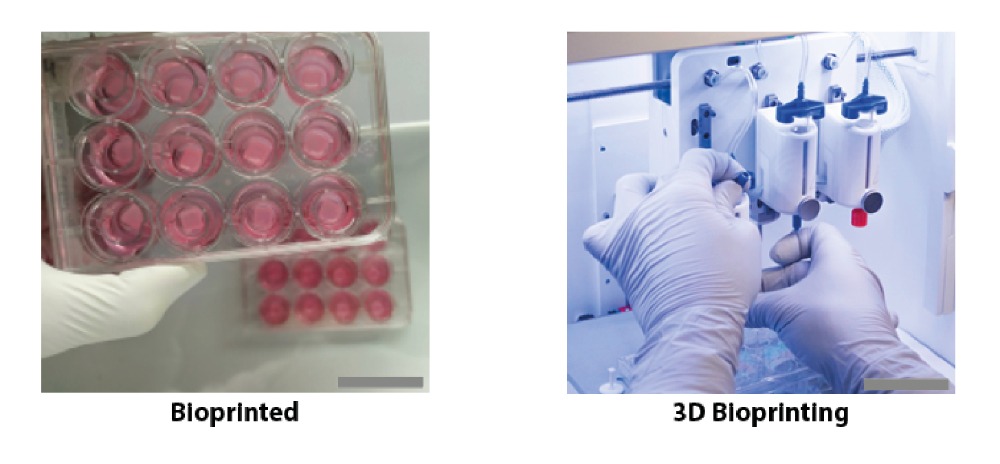

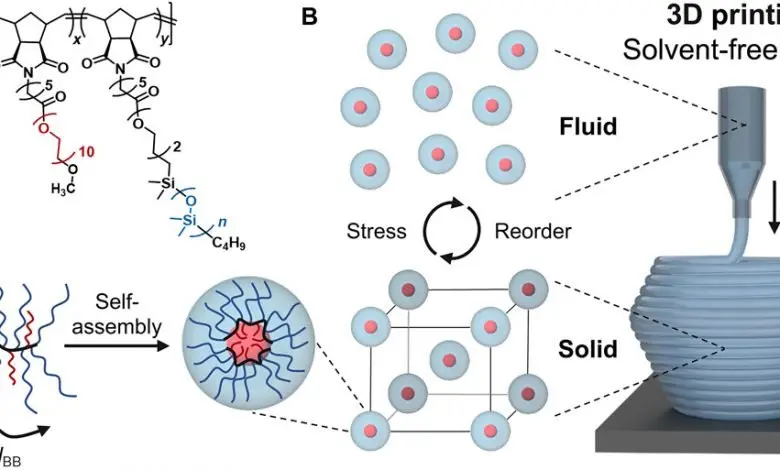

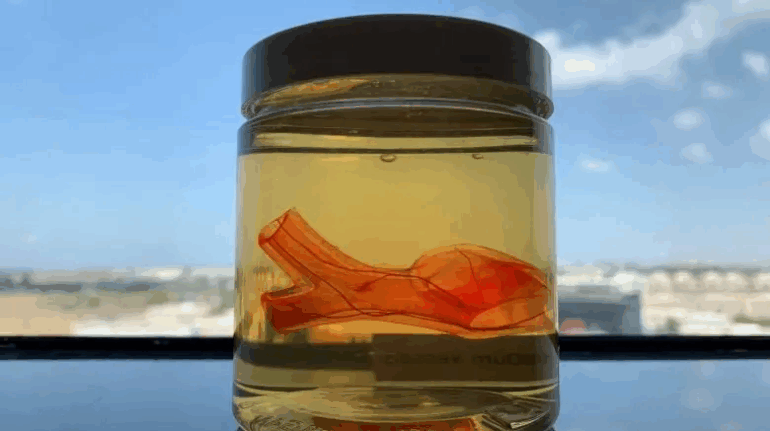

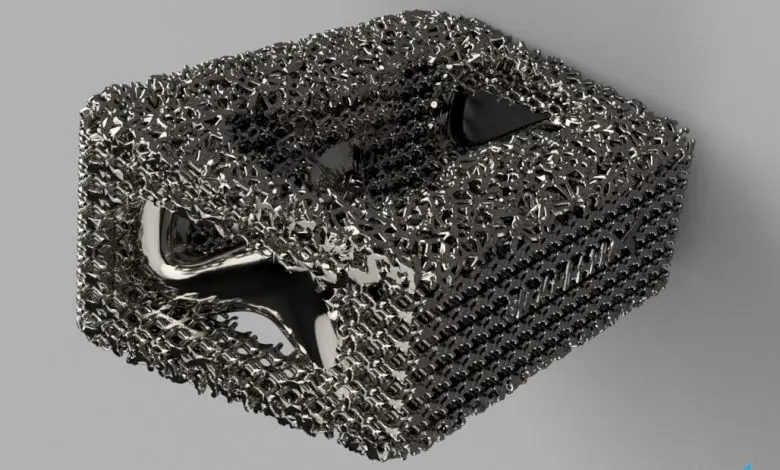

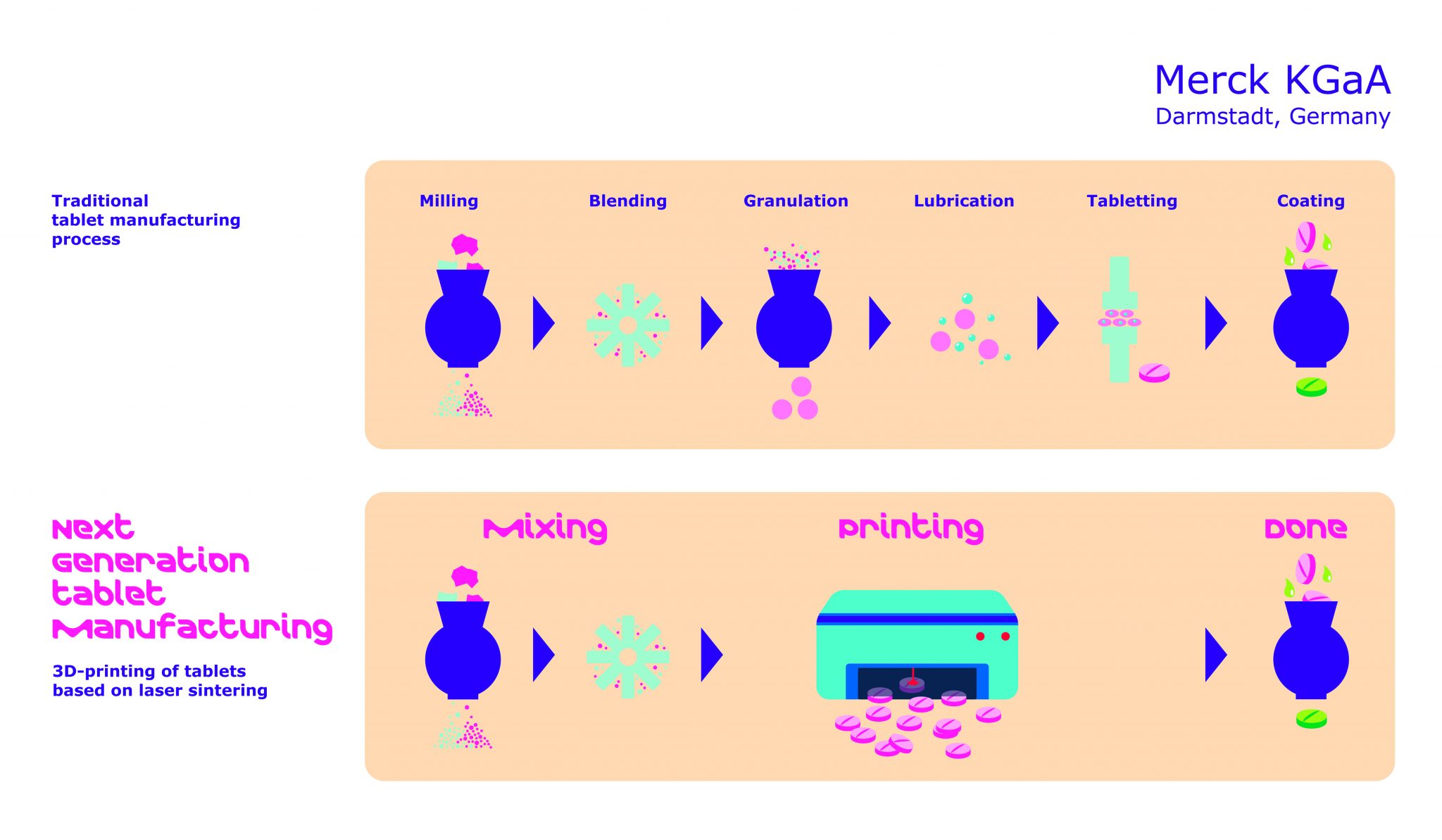

Triastek, Inc., a company specializing in 3D printing of pharmaceuticals, entered into a collaboration with Eli Lilly and Company, a leading global pharmaceutical company, to leverage the advantages of MED 3D printing technology to enable precisely targeted and programmed release of drugs in specific regions of the GI tract.