CollPlant Biotechnologies released a letter from its Chief Executive Officer, Yehiel Tal, to its shareholders. The letter summarizes a strong year for the company and its shareholders, which has benefitted from the uptick in 3D printing research and interest throughout 2020 to position itself for an even stronger 2021. The letter reads as follows:

Dear shareholders,

What a year it has been – and how it has changed our way of life! All of us have been affected in some way by Covid-19. We are optimistic that we will soon be able to return to normal life.

Despite the difficulties arising from the pandemic, we advanced several activities in 2020 making it a transformational year for CollPlant Biotechnologies.

Our partnerships

During the past year, we fostered existing partnerships and created new ones with Tier One companies. These collaborations further validate CollPlant’s technology as the gold standard in human collagen and the optimal building block for regenerative and aesthetic medicine.

2021 kicked off with the exciting news of CollPlant entering into a development and commercialization agreement with Allergan Aesthetics, an AbbVie company, for CollPlant’s type I recombinant human collagen (rhCollagen) to be used in dermal and soft tissue filler products. Combining rhCollagen’s superior properties with Allergan’s propriety technologies, this collaboration is expected to create a paradigm shift in the medical aesthetic field by providing next-generation regenerative products with long lasting results.

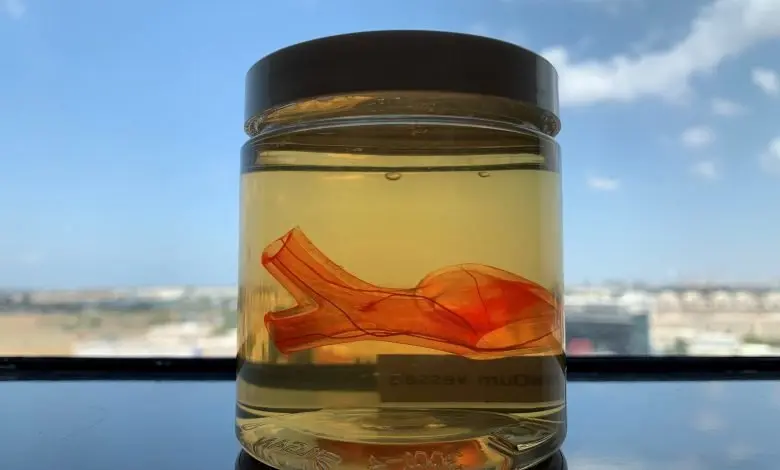

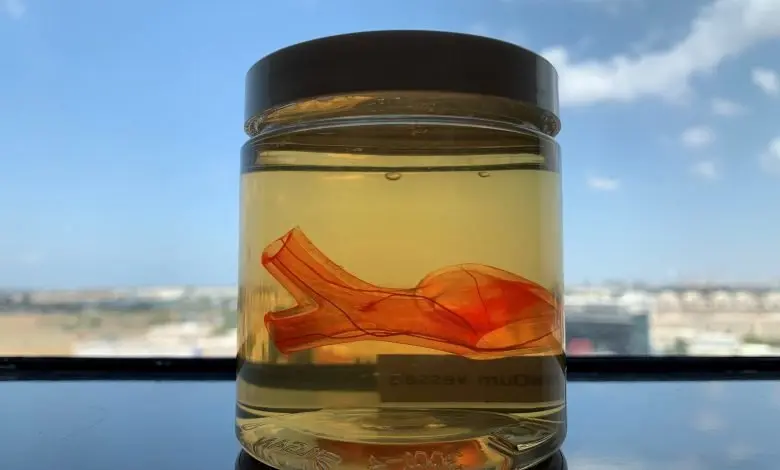

We expanded our collaboration with United Therapeutics which exercised its option with CollPlant to cover a second lifesaving organ, human kidneys, in addition to lungs. This expanded collaboration aims to help reduce global organ shortages of kidney transplants and potentially save the lives of millions of patients on kidney waiting lists.

CollPlant and 3D Systems have recently established a platform for collaboration in the field of 3D bioprinting, bringing together CollPlant’s expertise in rhCollagen-based BioInks and regenerative medicine, with 3D Systems’ expertise in 3D printing and healthcare. The collaboration aims to jointly address an unmet market need for a comprehensive solution to produce tissues and scaffolds for regenerative medicine applications.

We entered into a supply agreement with STEMCELL Technologies, Canada’s largest privately owned biotechnology company, for use of CollPlant’s rhCollagen in a broad range of cell culture applications. The recently signed agreement follows the companies’ established business relationship, which started in 2014 when STEMCELL began purchasing and incorporating CollPlant’s rhCollagen into some of its cell culture expansion and differentiation media kits. To date, hundreds of companies, as well as research and academic institutes, have used these kits for research and development projects. Under the supply agreement, STEMCELL distributes the kits globally for use in the regenerative medicine research market. The cell culture market is just one example of the vast potential of our rhCollagen platform technology in life science applications that have the potential to enable breakthroughs that improve patients’ lives.

Our product pipeline

Our R&D team continued accelerating development of all our major programs.

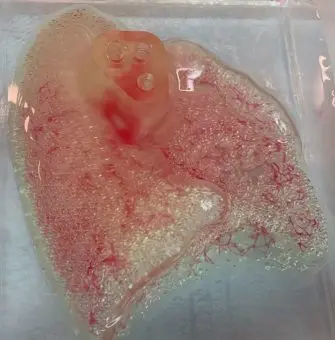

CollPlant develops a variety of BioInk formulations that are tissue and organ specific. These BioInks enable the printing of constructs that mimic the properties of the target tissues or organs to facilitate optimal regeneration. CollPlant’s rhCollagen has superior properties such as bio-functionality, homogeneity, and safety, and therefore it is the ideal building block for tissue and organ transplants used in regenerative medicine. Furthermore, CollPlant established a bioprinting lab to develop 3D bioprinted products alone or under collaboration with partners.

Manufacturing on Demand

Our development program for injectable and bioprinted regenerative breast implants is moving forward quickly. These implants are designed to gradually degrade and be replaced by newly grown natural breast tissue that is free of any foreign material. This program is currently in the pre-clinical phase. In addition, we are on track with the development of photocurable formulations which are based on rhCollagen and other ingredients for dermal/soft tissue filler products used in the medical aesthetics market. CollPlant granted AbbViea right of first negotiation to obtain a worldwide exclusive license for the abovementioned injectable breast implant and for the photocurable dermal filler products.

In November 2020, we announced our development program for an antiviral agent for potential treatment of COVID-19 patients. In-vitro early results of our formulations based on our proprietary rhCollagen imbedded with silver nanoparticles (AgNP) showed significant inhibition of avian coronavirus infectivity. Further studies are ongoing to optimize the formulations and doses. We intend to develop an anti-viral inhalation formulation to limit the spread of coronavirus in the upper and lower respiratory systems. With the pandemic inflicting a high human and financial toll, an available treatment can benefit millions worldwide and allow rapid recovery of social and economic activity while reducing the probability for new waves of infection.

Our activities in consortiums and societies

We continue to increase and cultivate our participation and leadership in societies and organizations that are at the forefront of creating industry standards and advancing biofabrication technologies.

As a member of the Industry Relations Committee of ISBF (International Society for Biofabrication), a scientific and professional society promoting advancements in biofabrication, I hosted ISBF’s virtual event held in January 2021. The event titled “Translation of laboratory discoveries into large scale manufacturing of tissues and organs” featured experts in the field from academia and industry, and attracted great interest and participation.

In January 2020, we partnered with the Advanced Regenerative Manufacturing Institute (ARMI), a consortium of over 150 partner organizations from industry, academia, and the U.S. federal government. ARMI’s mission is to make practical the large-scale manufacturing of engineered tissues and tissue-related technologies. As members of the ARMI consortium, CollPlant contributes its expertise in BioInks for 3D bioprinting of tissues and organs.

As part of the ARMI activity, CollPlant is also a member of two of the industry’s most respected and globally recognized technical standard development organizations – ASTM international, the American Society for Testing and Materials, and ASME, the American Society of Mechanical Engineers. Being a part of these committees enables us to contribute our expertise and knowhow in the development of industry standards for biofabrication, and positions CollPlant as a leading player in regenerative medicine.

We are concluding our 3rd year as a member at the ReMDO (RegenMed Development Organization) advanced biomanufacturing initiative, where we contribute to the development of a universal BioInk with tunable properties for 3D bioprinting of tissues and organs.

Our financials

CollPlant reports on a preliminary basis unaudited revenue of approximately $6 million for the year ended December 31, 2020, an increase of 160% compared to audited revenue of $2.3 million for the year ended December 31, 2019. Unaudited revenue for the year ended December 31, 2020 was derived mainly from sales of CollPlant’s BioInk for the development of 3D bioprinting of human lungs, the exercise of an option by United Therapeutics for licensing CollPlant technology to print kidneys, and sales of rhCollagen to AbbVie for medical aesthetics product development. CollPlant has approximately $50 million of unaudited cash reserves and no debt as of the date hereof. Unaudited cash reserves include $14 million that Collplant expects to receive in February 2021 as an upfront payment from AbbVie as part of the recently entered into strategic agreement with AbbVie.

I am happy with the increase in revenue from our long-term collaborators, as well as from our cash position that gives us the ability to execute our strategic plan. The preliminary estimate of revenue for the year ended December 31, 2020 and the unaudited cash reserve and debt as of the date hereof are based on currently available information, are subject to change and may vary from actual results. Collpant is under no obligation to update the preliminary estimate of revenue for the year ended December 31, 2020 and the cash reserve and debt as of the date hereof for any subsequent changes or events.

In summary

These are exciting times at CollPlant Biotechnologies. There is much to be proud of, and yet much more to do. We believe we have all it takes to become the leader in regenerative medicine, helping people live longer and better through our innovative collagen technology. My deep appreciation goes out to our employees for their dedication and commitment to the advancement of our activities throughout these challenging times. I thank the board of directors and all of our shareholders for your continued support. We greatly appreciate the trust you have placed in us and look forward to reporting our continuing progress during 2021.

Respectfully submitted,

Yehiel Tal,

Chief Executive Officer,

CollPlant Biotechnologies

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Adam Strömbergsson

Leave A Comment