BMW Presents Successful Implementation of IDAM Project

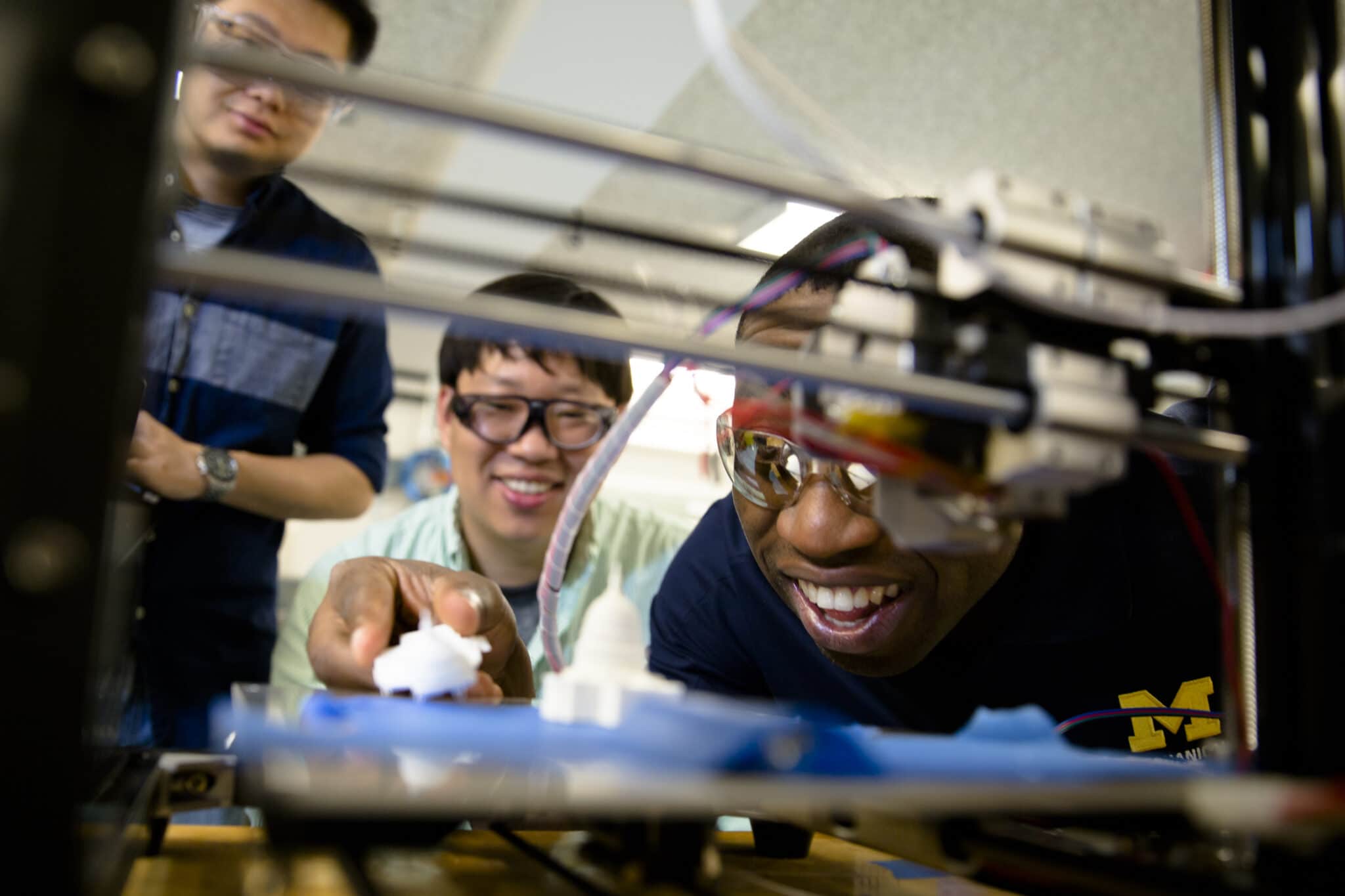

The Industrialization and Digitization of Additive Manufacturing project (IDAM project) for automotive series processes has been successfully implemented. The project consortium, funded by the Federal Ministry of Education and Research (BMBF), and led by the BMW Group, started three years ago with small and medium-sized companies, large companies, and research institutions. All members had a common goal – to revolutionize metallic 3D printing in the field of automotive series production.