Ingersoll and MELD are Developing a Metal 3D Printer for Vehicle-size Parts

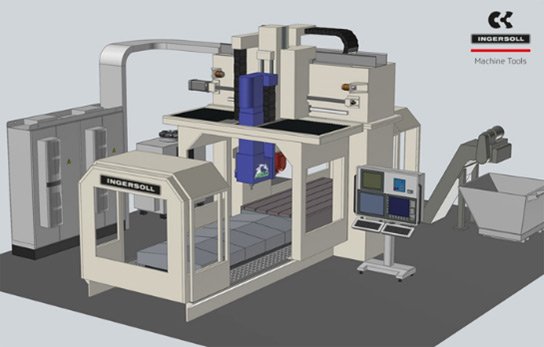

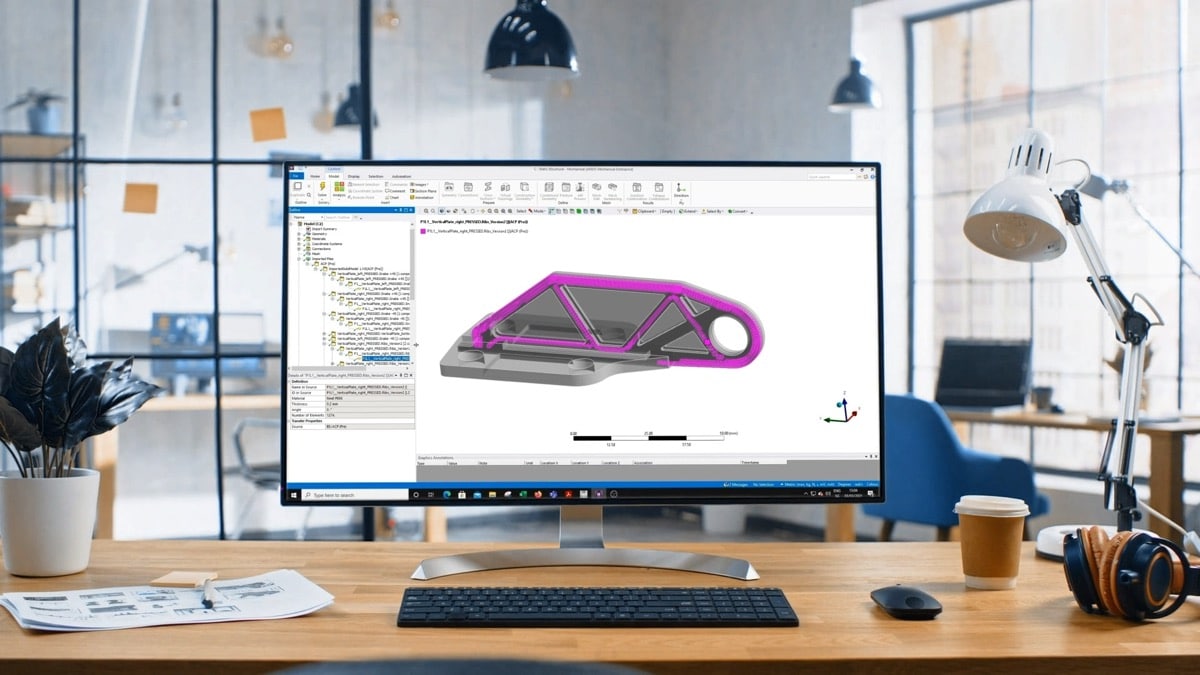

Norbert J. Kott, US Army DEVCOM-GVSC Materials, Additive Manufacturing (Detroit Arsenal, Warren, MI) reports in an article that appeared on the SME’s website that they US Army is working with LFAM 3D printer manufacturers Ingersoll (part of the Camozzi Group) and Virginia-based MELD Manufacturing on the Jointless Hull project. Goal of the project is the development of a metal 3D printer that is capable of producing parts as large as an entire vehicle.