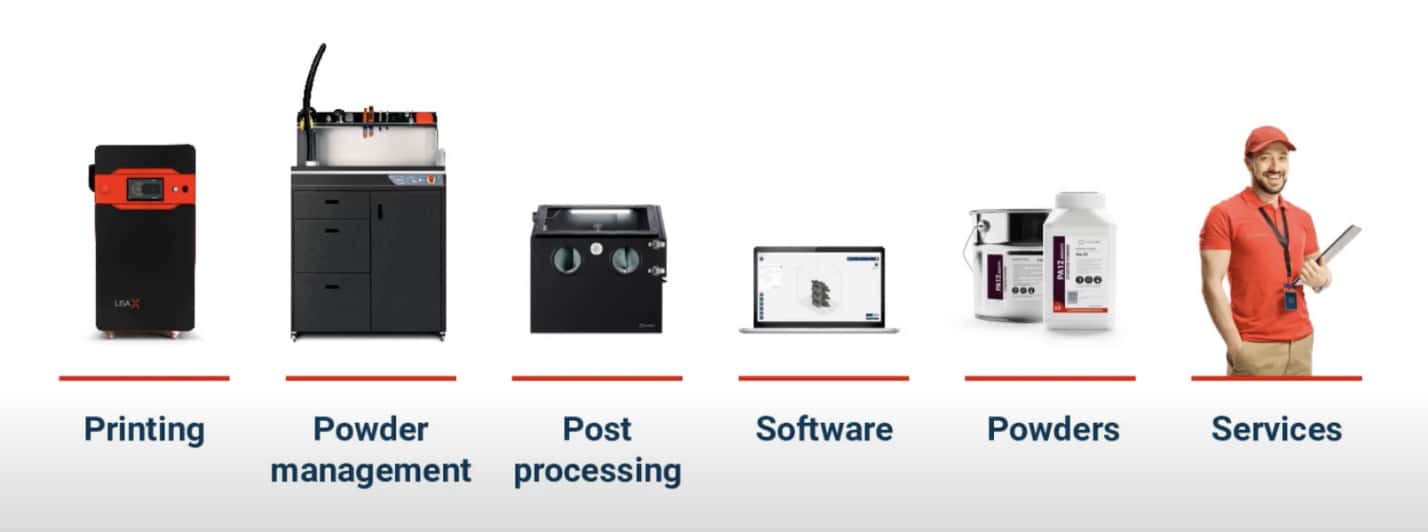

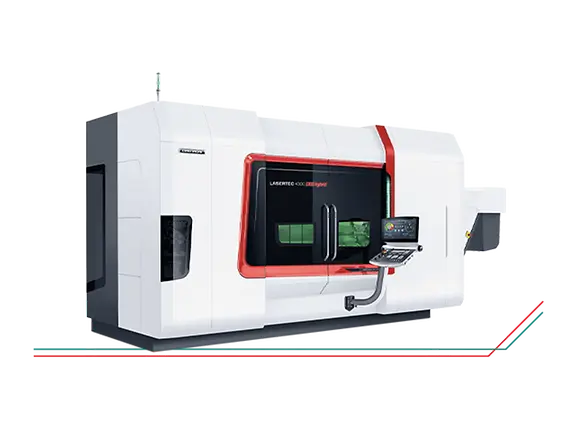

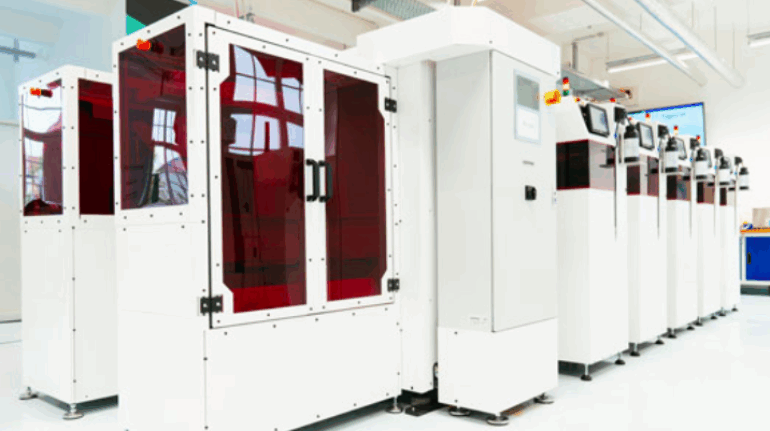

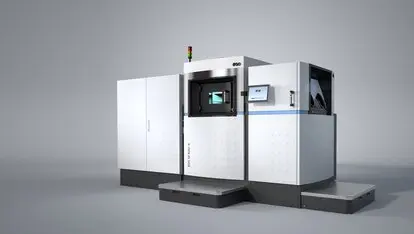

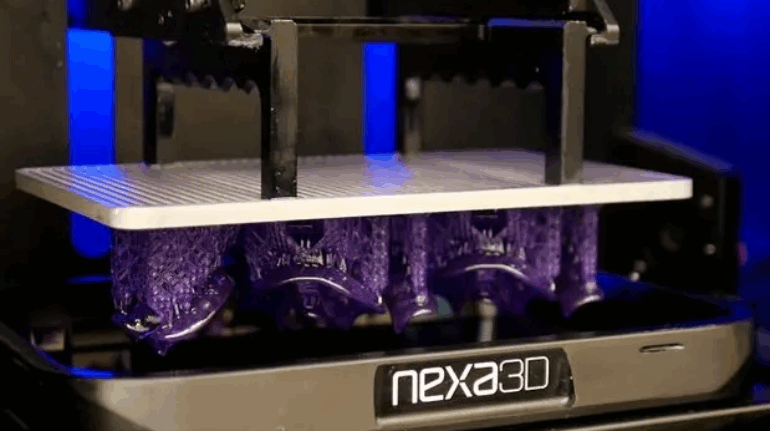

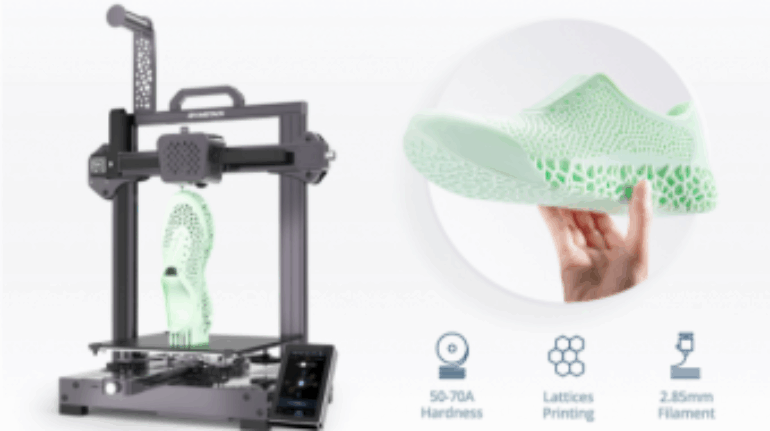

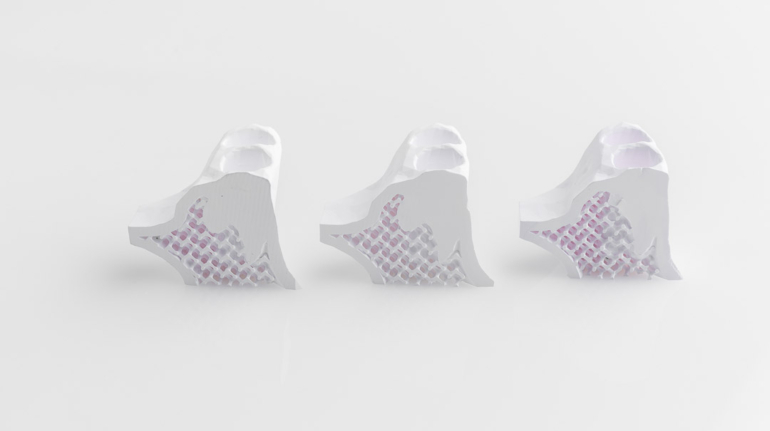

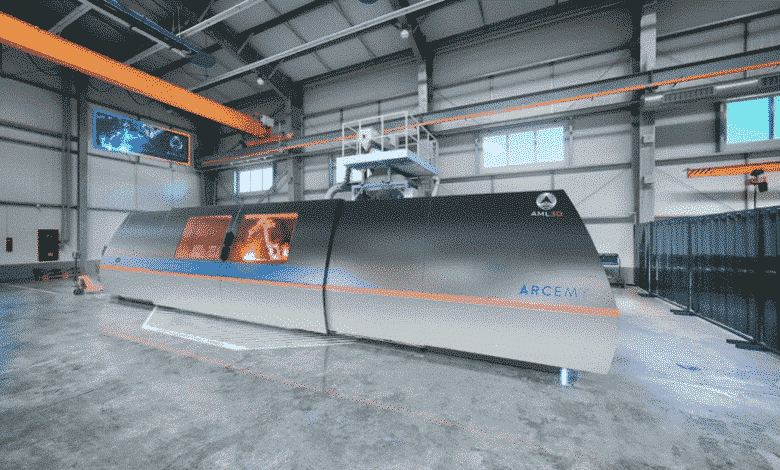

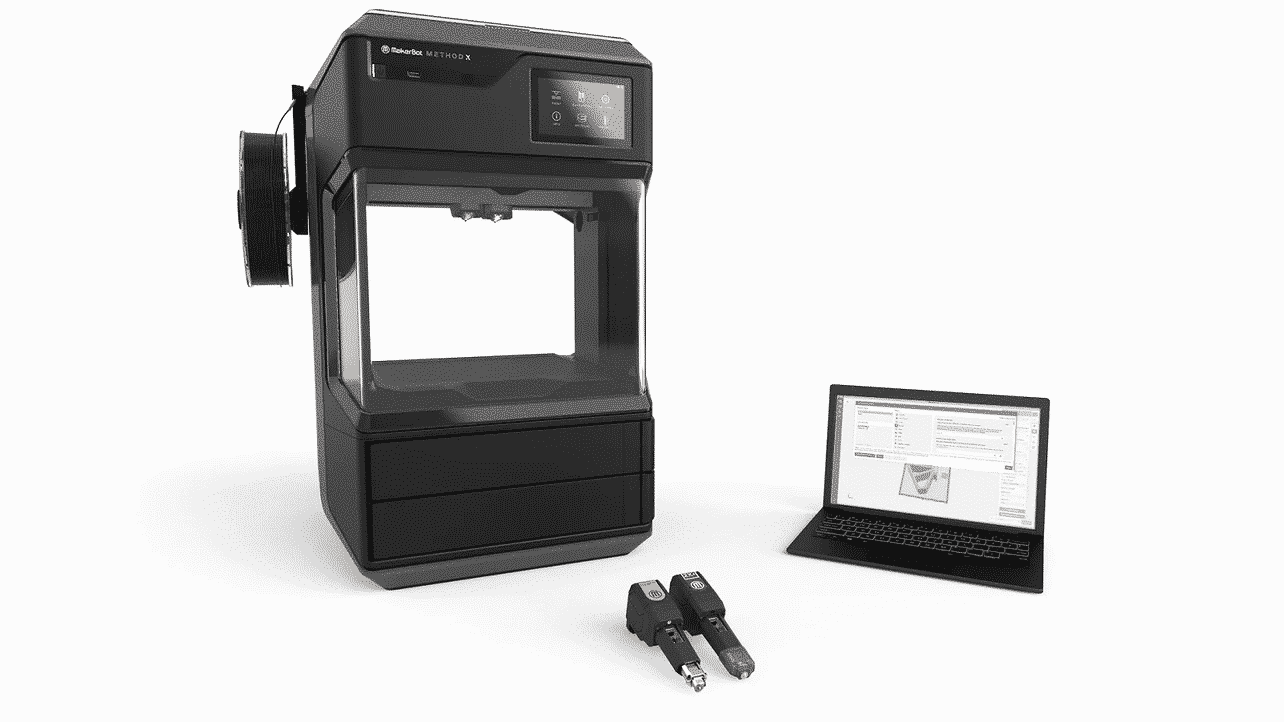

BOSTON, MA (USA) – GE (NYSE: GE), the world’s leading digital industrial company, today announced plans to acquire two suppliers of additive manufacturing equipment, Arcam AB and SLM Solutions Group AG for $1.4 billion. Both companies will report into David Joyce, President & CEO of GE Aviation. Joyce will lead the growth of these businesses in the additive manufacturing equipment and services industry. In addition, he will lead the integration effort and the GE Store initiative to drive additive manufacturing applications across GE. “Additive manufacturing is a key part of GE’s evolution into a digital industrial company. We are creating a more productive world with our innovative world-class machines, materials and software. We are poised to not only benefit from this movement as a customer, but spearhead it as a leading supplier,” said Jeff Immelt, Chairman and CEO of GE. “Additive manufacturing will drive new levels of productivity for GE, our customers, including a wide array of additive manufacturing customers, and for the industrial world.” GE expects to grow the new additive business to $1 billion by 2020 at attractive returns and also expects $3-5 billion of product cost-out across the company over the next ten years.