What happens if you combine a thousand-year-old castle overlooking the sea in Liguria and a startup that produces aerospace parts in additive technology with anthropomorphic robotic arms? You may be in for one of the most unforgettable experiences ever at the 3D printed suite of the Capitolare Tower, in Porto Venere, Liguria, Italy. 3dpbm will be visiting the Tower for its grand opening next week and we’ll bring you more exclusive images.

The Capitolare Tower is the first hotel suite entirely produced with additive technology. The challenge was made possible by Andrea Borlenghi, an entrepreneur with extensive experience in the 3D/AM world. The Tower of the Portovenere castle is an ancient structure, with walls that have withstood sieges for centuries. It is still possible to find in the rocks of the tower the scars left by the centuries-old battles fought to conquer that strip of land. The tower was built to protect the village from the nearby Pisan Duchy. Later it was used to defend against pirate raids. Now that the pirates are gone, the tower has become a jewel of innovation ready to meet the needs of the most demanding tourists. It will be a luxury 3D printed suite, overlooking breathtaking seaside.

The Capitolare Tower 3D printed suite comes from the vision of Andrea Borlenghi, an experienced entrepreneur in the global AM industry.

For those who may not be familiar with the location of the Cinque Terre (Five Lands) in the region of Liguria, where Porto Venere is located, they also provided the setting to the recent Disney Pixar movie Luca.

The entire interior design of the 3D printed suite was done by designer Federica Cristaudo, whom our readers may remember from a previous (ice cream) scoop by 3dpbm: the Riso Paradiso 3D printed ice cream parlor in Sicily. The recurring theme in the interpretation of design is the movement of the sea. It can be found in colors, materials, shapes. The particularity of the intervention arises from the mixture of 3D Printing in synergy with applied arts dating back to the 12th century.

“I was born and raised in contact with the great world of conservative restoration of works of art, in close contact with what would soon become my world,” Federica says about her work. “I absorbed this by developing a form of intervention that puts together the two extreme time concepts, YESTERDAY/TOMORROW, pursuing continuous research where the common denominator remains ECO-FRIENDLY RESPECT always looking UP!”

Manufacturing on Demand

The attention to the search for new materials has led to the use of remains deriving from shells and recycled material that are upcycled with additive technology following a closed-circuit production process, reducing its emissions to almost zero. In this particular case, the materials used are recycled polypropylene with 20% glass fiber reinforcement.

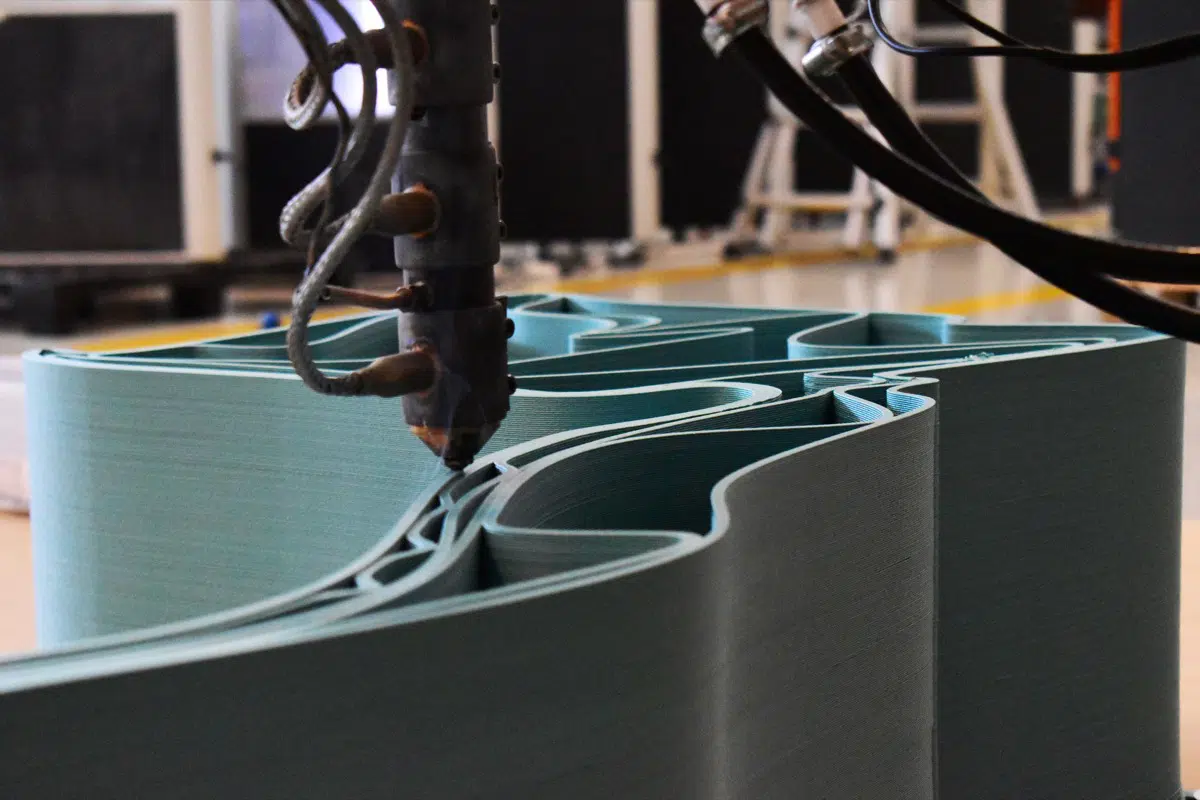

The engineering and printing process for the furniture in the 3D printed suite was provided by Caracol Additive Manufacturing and the company’s development facility. Caracol is an innovative SME from Lombardy, Italy, which offers advanced additive manufacturing solutions, without limits of scale. In addition to working on developing projects for sectors from aerospace to automotive, from energy to design and architecture, the company has developed a large additive manufacturing robotic system.

The additive technology used is a system that includes a patented extrusion head and an integrated software platform, elements that allow Caracol to produce components without limits of scale, geometry and materials. In addition to the very large components, the system is capable of producing components with complex geometries by working on 6 axes instead of the standard 3 axis used in most 3D printing processes.

This makes it possible to produce parts at 45° or 60° angles to create hollow geometries such as those used in boats and canoes). In addition, a wide variety of advanced technopolymers and recycled plastics can be used when working with direct-printing of the material in pellet form. The developed solution, therefore, offers various benefits in terms of costs, production times, and the elimination of waste that would be generated with traditional methods.

This marriage of design and technology was inspired by the closing slide of Steve Jobs’ 2011 annual product presentation. It ended with a slide that showed the intersection of road signs bearing the words “liberal arts” and “technology”. That picture was taken at Stanford. And Steve Jobs in an interview with Walter Isaacson said that every great innovation could only be born in that intersection. Where art meets technology.

For those who may not be familiar with the location of the Cinque Terre (Five Lands) in the region of Liguria, where Porto Venere is located, they also provided the setting to the recent Disney Pixar movie Luca.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment