Shapeways, a global digital manufacturing platform driven by purpose-built software, offers five predictions for additive manufacturing in 2022 based on strong market momentum, increased technology investments, and strengthened industry partnerships and collaborations over the past year.

“We expect additive manufacturing to gain significant traction in the coming year, especially in digitizing, automating, and innovating critical manufacturing workflows,” said Greg Kress, CEO of Shapeways. “As traditional manufacturers increasingly enjoy newfound operational and cost benefits, we forecast an increased cadence of 3D printing adoption, which will drive the development and delivery of more customized and personalized products while alleviating lingering supply chain challenges.”

Digital workflows

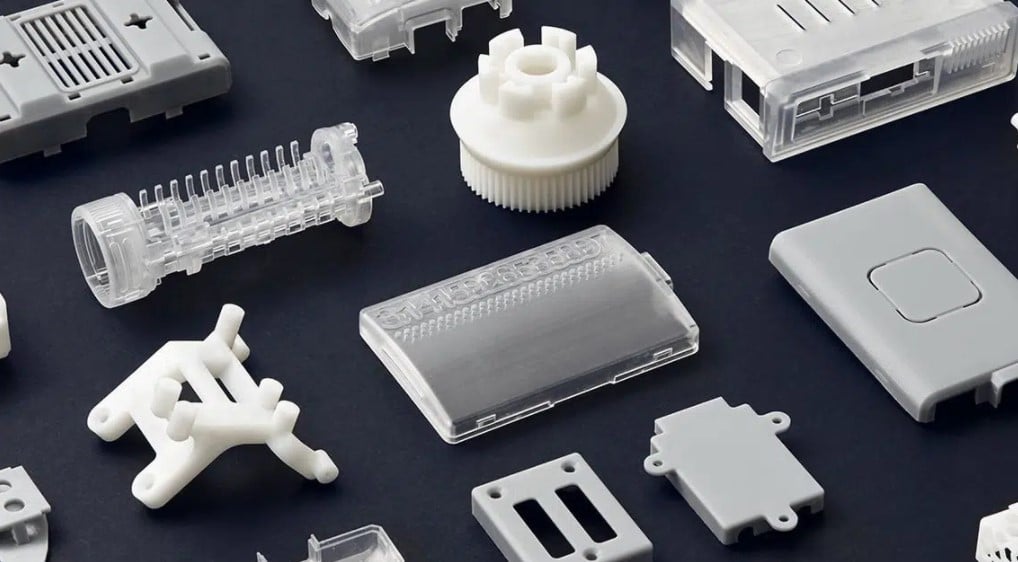

Interest in additive manufacturing will surge, especially in addressing demands for high-mix, low-volume production runs. This will motivate manufacturers of all kinds and sizes to transform their operations through the use of increasingly digital, end-to-end manufacturing processes. Companies that embrace new ways of doing business with digitized, additive manufacturing will reap the benefits of enabling product design innovations and faster time to market while reducing capex and inventory costs.

Purpose-built software

Traditional manufacturers, large and small, certainly know the value of software. Whether it’s an ERP, CRM or CEM, for decades software has been an integral part of streamlining operations while helping meet demands for high-volume production with superlative quality and efficiency. Yet what has been missing is purpose-built software designed specifically to support additive manufacturing’s unique process flows regarding how products are designed, made, and delivered.

Shapeways’ recent Otto software announcement gives manufacturers a way to gain free access to 3D printing by automating processes while validating quality end to end. While 3D printing now is mainstream among 75% of the mid-sized manufacturers polled in Shapeways’ recent “State of 3D Printing” survey, more flexibility is needed to meet demands for quality, personalization, and sustainability.

Manufacturing on Demand

Customization is king

Embracing additive manufacturing yields the potential to design, create, and deliver products that are limited only by one’s imagination. While this pertains to every conceivable market, arguably none can make as life-changing a difference in daily lives as the potential for additive manufacturing in the medical/healthcare markets. A recent market report expects the 3D printing medical market to grow from $2.4B this year to $5.1B by 2026. Expect massive advancements in 3D-printed surgical guides and instruments as well as customized implants, wearable devices, and prosthetics.

Other markets like NFTs (short for non-fungible tokens) have been around for a while, but are just coming into their own as a substantial way to invest or increase revenue. Appealing to buyers as a unique digital currency, it is easy to see why NFTs are so easily translated to the 3D printing industry. For businesses around the world, this opens up an infinite and so far untapped market of opportunities for digital files turned into 3D printed models–allowing NFTs to come to life in full color, with a wide range of options in materials and finishings. In some cases, NFT models are also sold as an alternative to owning the actual digital file, leaving the door open to sizable production runs, depending on the popularity of an item.

Alleviating supply chain woes

Savvy organizations understand that additive manufacturing has an important role to play in reducing the lingering effects of supply chain disruptions. Not only does 3D printing permit products to be manufactured on-demand, but it also enables them to be produced and delivered locally. This reduces logistics requirements, including transportation and local storage, to ensure on-time, on-budget fulfillment.

Investments and partnerships

Headlines were busy in 2021 reporting on the constant activity in the additive manufacturing market. Aside from Shapeways’ IPO in late September, market watchers followed additional IPOs, M&A transactions, and a steady stream of new partnerships. Shapeways also announced a partnership with Desktop Metal to ensure broader access to world-class additive manufacturing services.

In 2022, the level of interest should continue rising as well-known names in the manufacturing and consumer goods industries step up their interest and investments in 3D printing technologies and services. At the same time, continued innovations may come from groundbreaking start-ups or smart collaborations among players of all kinds. Shapeways’ survey found that 68% of industry executives polled agreed that 3D printing is the future of manufacturing.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Andrea Gambini

Leave A Comment