Project DIAMOnD (Distributed, Independent, Agile Manufacturing On-Demand) has joined the growing number of organizations which have committed to 3D printing aid for those Ukrainians injured by Russian troops.

With Ukraine still under siege by Russian forces, the Ukrainian Defense Ministry has called for wound-bandaging tourniquets to be shipped into the country, triggering initiatives across the 3D printing industry. Now Automation Alley’s Project DIAMOnD has added to these efforts, by mobilizing every 3D printer in its network to create tourniquet clips, which it plans to ship to Makershelp for assembly.

“The specific part the Ukrainian government needed was a tourniquet clip that cannot be easily produced using conventional means quickly because of turnaround times in mold making,” explains Pavan Muzumdar, COO of Automation Alley. “The 3D printers and the Onyx material we have available through Project DIAMOnD was a perfect fit for this application.”

“We are grateful to be able to help the people of Ukraine in some way.”

Automation Alley’s Project DIAMOnD

Launched by Automation Alley, a World Economic Forum Advanced Manufacturing Hub (AMHUB), Project DIAMOnD was initially established as a PPE production network amid the start of the COVID-19 pandemic in 2020. Since then, however, the organization says its initiative has grown into the USA’s “largest distributed 3D printing network.”

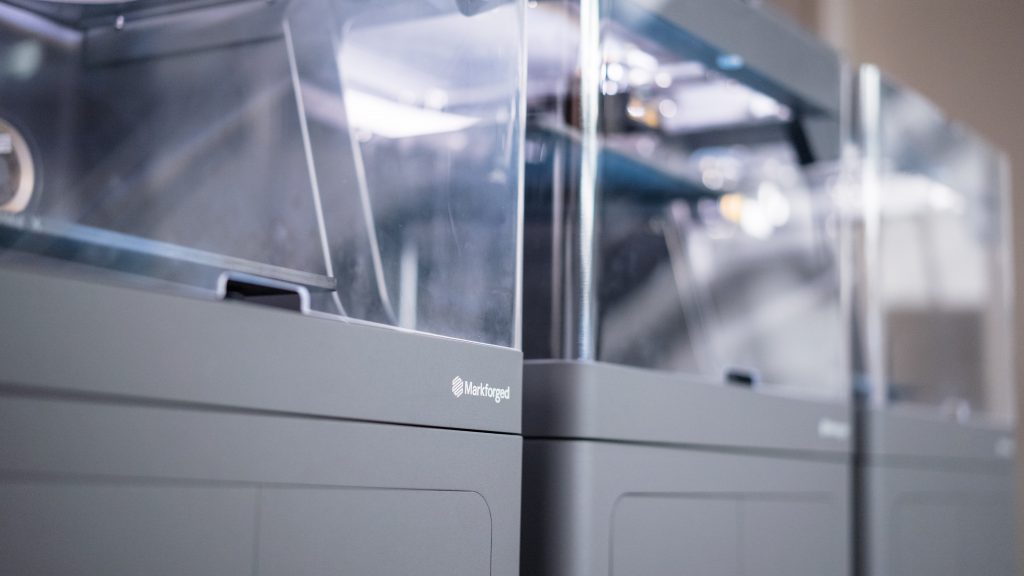

Already, the project has attracted an impressive list of contributors, with Markforged, Microsoft, Autodesk, Giggso each committing their support. As this expansion has continued, the likes of 3YOURMIND have also joined Project DIAMOnD, with the aim of using its Agile ERP and Agile MES programs to help coordinate production across participating facilities in a streamlined way.

In practice, the project has seen contributors pool their resources via a decentralized cloud network, through which they can band together to fulfill large orders, thus allowing them to keep their production workflows operational 24/7, and immunize their operations against supply chain disruptions.

Heeding Ukraine’s call to action

Ever since Russia launched a full-scale invasion of Ukraine in late-February 2022, there has been a concerted effort to get humanitarian supplies into the country, to help those caught up in the fighting. With organizations across the 3D printing sector wanting to do their bit to help, this has led many to begin producing tourniquets, which are essentially devices designed to stop severe bleeding.

One of the first to do so was Glia, which launched an open-source tourniquet 3D printing campaign in early-March, that saw it publish its own medical device design and seek to raise $25,000 towards mass-producing it. This was followed by another initiative in Spain, through which BCN3D 3D printed 300 tourniquet parts, before delivering them to hospitals in the Ukrainian cities of Kryvyi Rih and Dnipro.

Manufacturing on Demand

Aiming to do its own bit to aid these humanitarian efforts, Project DIAMOnD has now also announced plans to produce tourniquet parts via its distributed manufacturing network of 300 3D printers. Once ready, it’s expected that these tourniquet clips will be shipped over to the Danish organization Makershelp, itself a Glia and Ukraine-Denmark Humanitarians partner, which intends to turn them into usable devices.

According to Project DIAMOnD’s organizers, the initiative demonstrates once again that “in times of crisis, 3D printing is the ideal technology to produce needed parts,” not only due to its “flexibility and speed,” but the way it’s able to take advantage of designs which are “shared digitally among multiple locations and producers.”

“Project DIAMOnD has allowed us to experiment with 3D printing and innovate for our own business while simultaneously giving us the opportunity to aid in humanitarian efforts when called upon. It’s a win-win,” added Richard Canny, President of Ultimation Industries, LLC, a Michigan-based conveyor manufacturer. “Through Project DIAMOnD, we’ve been able to implement a full digital process and we are really happy to be able to assist with this particular Ukrainian effort.”

“It’s a small thing, but we are delighted to be able to help out. It’s one great example of how additive manufacturing can respond to a need like this quickly.”

AM stands up to Russian aggression

The 3D printing industry has been almost unequivocal in its condemnation of Russia’s invasion and its support for the Ukrainian people. Not long after Russia launched its full assault on the country, 3D printing industry leaders stated their support for NATO’s policies against the Putin regime, and expressed “solidarity with all people affected by the war.”

EOS, 3D Systems and HP are also amongst a number of 3D printing firms now refusing to do business in Russia, as a means of taking a stand against Russian military aggression. In the case of Zortrax, the Polish 3D printer manufacturer has even terminated negotiations over a hugely-lucrative share deal with a Russian investor in light of the ongoing invasion.

Elsewhere, in more positive events, 3YOURMIND has begun working with Sygnis and TeenCrunch to support the ‘Tech Against Tanks’ initiative. Thus far, the project has mainly focused on aiding the production and distribution of 3D printed medical, tactical and protective equipment from printing hubs and makers across Poland, Germany and Ukraine.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment