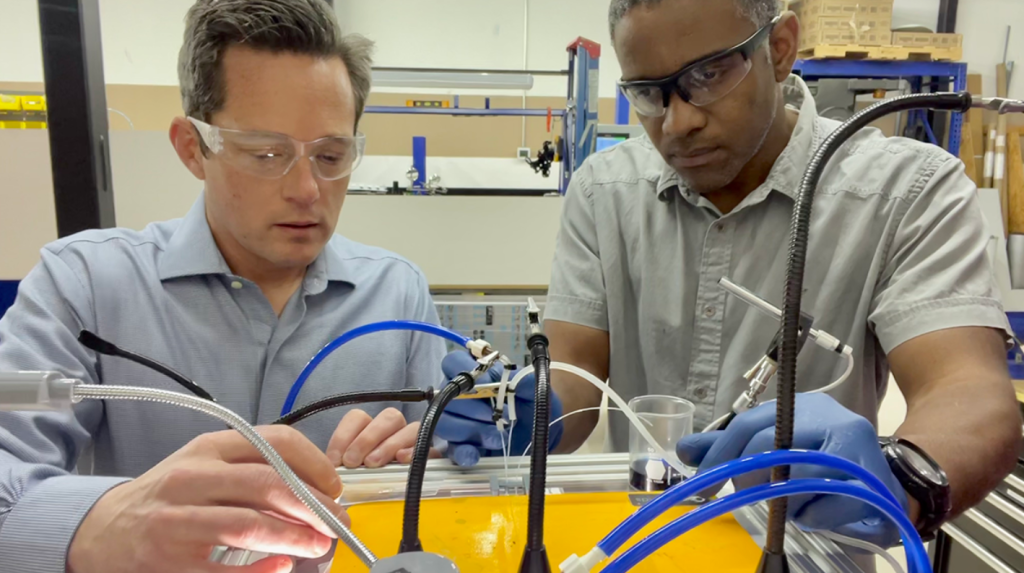

North Carolina-based medical 3D printing startup Phase has secured a $1.8 million grant from the National Institutes of Health (NIH) to advance its work in 3D printing technology for microfluidic organ-on-a-chip models.

The primary focus of this grant is the development of a blood-brain-barrier model that accurately replicates the in vivo environment, aiming to address current limitations in treating neurological diseases and brain cancer. Partnering with Harvard Medical School’s Massachusetts General Hospital, Georgia Tech, and Virginia Tech, the two-year grant from the NIH’s National Center for Advancing Translational Sciences aims to develop and test 3D printing technology for microfluidics for biomanufacturing and creating organ-on-a-chip models.

“With the support of the NIH and with this team of leading researchers, we believe this project will not only help create a better blood-brain-barrier model, but also lay the foundation for creating other organ-on-a-chip models that will greatly benefit researchers and patients alike,” said Jeff Schultz, Ph.D., MBA, and Co-Founder of Phase.

Replicating human physiology on a chip

Employing 3D printing, Phase fabricates microfluidic models using biocompatible materials such as PDMS, achieving a resolution commensurate with biological scales. This technology enables the incorporation of valves, sensors, and electrodes throughout the printing process, streamlining production with automation and reproducibility. The project’s significance is underscored by the growing regulatory focus on alternatives to animal testing in both the United States and the European Union.

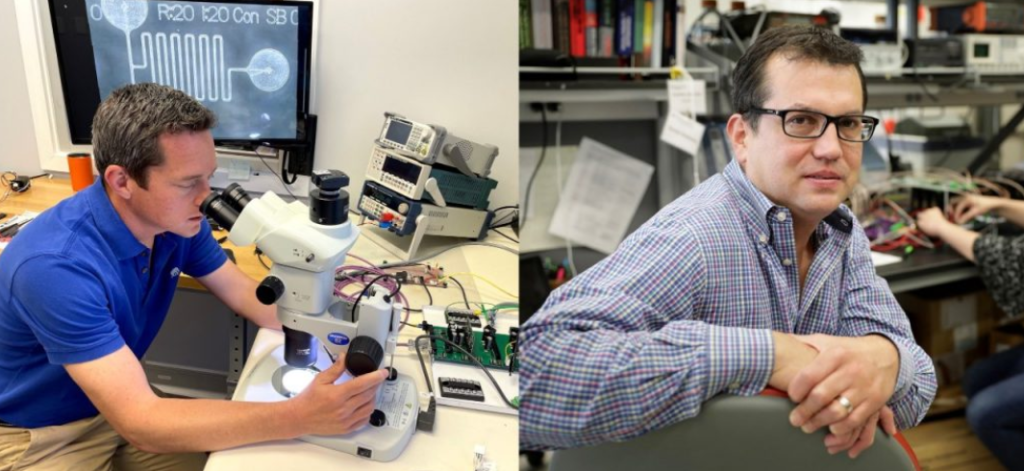

Key researchers from collaborating institutions include Seemantini Nadkarni, an associate professor at Harvard Medical School and Massachusetts General Hospital. Nadkarni is leading the development of a system to test PDMS kinetics during organ-on-a-chip device creation. Rafael Davalos, a professor of biomedical engineering at Georgia Tech, is overseeing functional testing of the blood-brain-barrier model. Additionally, Amrinder Nain, a professor of mechanical engineering at Virginia Tech, is responsible for fabricating ultra-thin and nanoporous membrane mimics for the model.

The NIH grant builds upon previous investments and support from governmental and biotech institutions, including the Phase I SBIR grant, NC Biotech Small Business Research Loan, One North Carolina Small Business Program grant, participation in the WheelsUP program, and an NIH TABA award to identify market opportunities. These initiatives collectively aim to support innovation and growth within the life science sector.

Organ-on-a-chip models: the next arrow in the quiver of the healthcare sector

Manufacturing on Demand

Developments regarding organ-on-a-chip models and microfluidics are emerging as crucial tools in drug development and toxicity testing. Just last month, researchers from Université de Montreal‘s Centre de recherche Azrieli du CHU Sainte-Justine developed a bioink for 3D printing “heart on a chip” devices. Using automated 3D bioprinting, the team produced ring-shaped cardiac devices with varied cell types.

According to the researchers, the models promise a better understanding of heart diseases and drug development. Combining GelMA, AlgMA, and rGO, this bioink was optimized for cardiac tissue engineering, a first for AlgMA. It supports cell viability and function, crucial for mimicking real heart behavior. The team aims for personalized treatment by printing patient-specific heart models.

On another note, five Belgian companies and research centers have joined forces for the AstroCardia project, aiming to manufacture an artificial heart and circulatory system for space exploration. This initiative plans to deploy a heart-on-a-chip model aboard the International Space Station (ISS) by 2025. The project aims to investigate the accelerated aging processes of the human heart in the unique environment of space. By leveraging living stem cells and specialized bioink, researchers hope to replicate human heart tissue accurately.

You might also like:

Materialise’s new TMJ Arthroplasty System brings hope for jaw treatments: Dubbed TMJ Total Arthroplasty System, this solution offers a comprehensive approach to personalized treatment from a single company. The temporomandibular joint connects the jawbone to the skull, serving a critical function. For individuals with severe TMJ complications requiring joint replacement, Materialise’s new system provides a tailored solution that combines implants, guides, and digital planning, streamlining the treatment process.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Ada Shaikhnag

Leave A Comment