Following the success of a breakthrough eye transplant, Belgian 3D printing company Materialise has introduced its latest solution to treat patients requiring total temporomandibular joint (TMJ) arthroplasty.

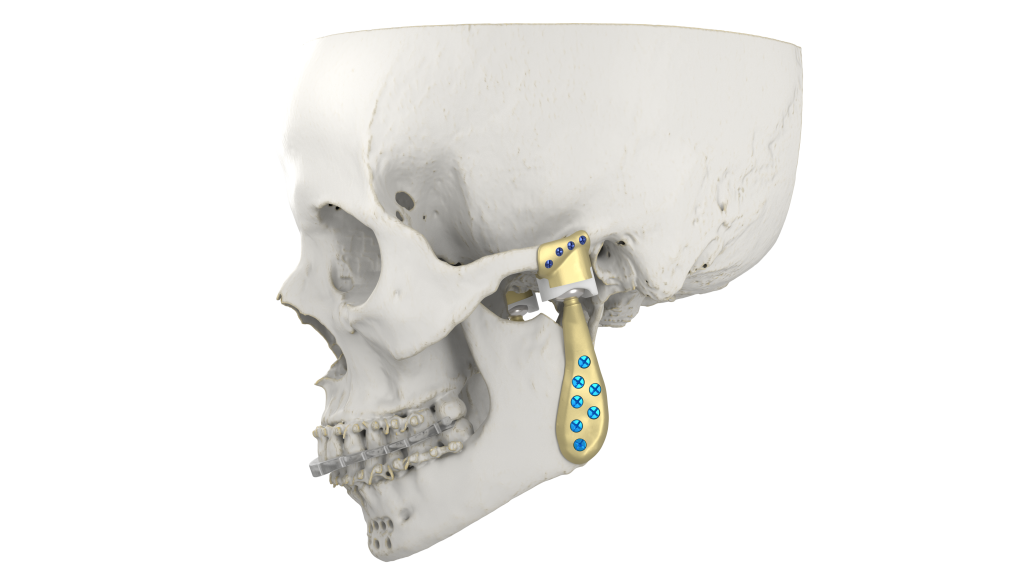

Dubbed TMJ Total Arthroplasty System, this solution offers a comprehensive approach to personalized treatment from a single company. The temporomandibular joint connects the jawbone to the skull, serving a critical function. For individuals with severe TMJ complications requiring joint replacement, Materialise’s new system provides a tailored solution that combines implants, guides, and digital planning, streamlining the treatment process.

“Our TMJ Total Arthroplasty System provides a completely personalized solution. It allows the seamless transfer of the virtual preoperative surgical plan to the operation room, enabling the functional reconstruction of the temporomandibular joint,” said Maarten Zandbergen, Market Manager CMF at Materialise. “This comprehensive solution offers clinicians full support for this complex procedure. It truly facilitates personalized treatment by providing a complete system including virtual planning software and clinical engineering support, as well as surgical guides, screws, and the implant itself.”

Customized approach to TMJ surgery

Promising outcomes have been observed, based on a clinical study involving patients who have undergone the TMJ prosthesis procedure. Outcomes reported improved quality of life, reduced pain levels, heightened satisfaction, and improved eating ability post-surgery, with an exceptional 97% accuracy rate in implant placement reported. Moreover, clinicians also revealed a 100% success rate with the TMJ system one year post-surgery, underscoring its efficacy.

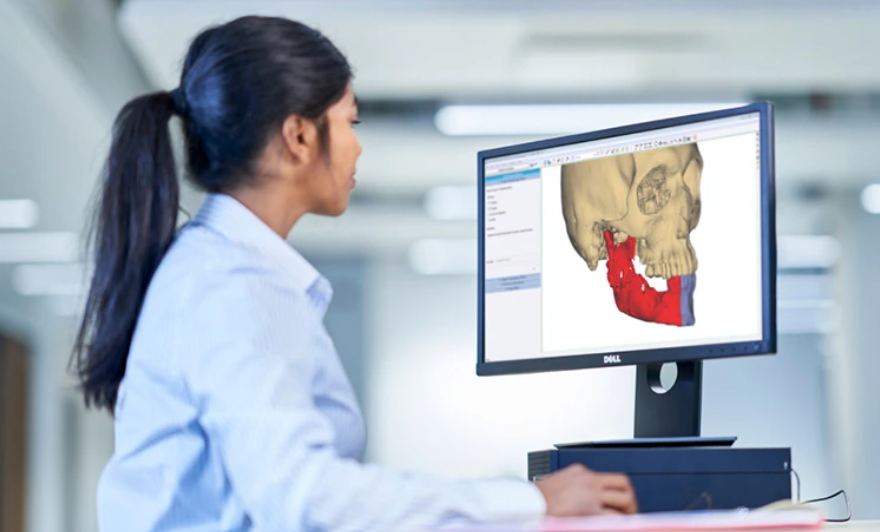

At the core of Materialise’s TMJ system lies a fully digitalized workflow, ensuring both efficiency and precision based on each patient’s unique anatomy. Clinical engineers from Materialise work closely with surgeons throughout the digital planning process, culminating in the production of personalized TMJ implants within Materialise’s facilities. This cohesive approach not only ensures compatibility with Materialise’s broader personalized cranio-maxillofacial (CMF) solutions but also extends access to tailored treatment options.

The digitalized workflow commences by acquiring the patient’s CT scan and dental information. During an interactive online session, a Materialise clinical engineer collaborates with the treating physician in surgical planning and device design. Upon finalization of the planning and device design, Materialise undertakes the manufacturing process of the personalized TMJ implant within its facilities. Subsequently, the surgeon is equipped with the necessary implants and instruments for the surgical procedure.

“Our implants, instruments, 3D planning technology, and clinical support empower surgeons as they strive to achieve precise and reliable outcomes,” said Martijn Orye, CMF Market Specialist. “Personalized solutions are becoming the primary choice for more challenging or complex cases such as TMJ replacements. Our complete solution streamlines and speeds up what used to be a slow personalization process with other providers.”

Materialise’s TMJ Total Arthroplasty System is currently available to surgeons in Europe, the UK, and Brazil. This launch follows closely with the establishment of a new medical 3D printing facility in Michigan, dedicated to producing personalized titanium CMF implants for facial reconstructive surgery. Before this facility’s opening, Materialise solely manufactured titanium CMF implants in Belgium. With the Michigan facility’s launch, the company aims to expedite delivery times for personalized implants to hospitals across the United States.

3D printed implants modernize oral care

Manufacturing on Demand

Over the years, 3D printing has played a pivotal role in offering customized jaw treatments by allowing for precise surgical planning and the creation of customized implants and guides, potentially leading to faster recovery times, and better patient experiences. For instance, Dimension Inx introduced CMFlex, its FDA-approved 3D printed bone graft, which was used in two clinical cases. It was utilized for surgeries of the lower jaw, specifically mandibular angle augmentation, as well as surgeries of the upper jaw, known as maxillary segmental osteotomy surgeries.

Comprised of hydroxyapatite and a blend of biodegradable polymers, CMFlex exhibits properties such as fluid absorption, bleeding control, and facilitation of bone remodeling. Surgeons can anticipate the broader availability of CMFlex in 2024, providing them with a customizable solution for addressing bony defects in oral and maxillofacial procedures. Dr. Brian Farrell, DDS, MD, from the Carolinas Center for Oral & Facial Surgery, and Dr. Derek Steinbacher, Director of West River Surgery Center, and were the surgeons behind the successful completion of the two surgeries utilizing CMFlex.

Back in 2022, Cerhum introduced MyBone, the first 3D printed bone graft to gain approval under Medical Device Regulation 2017/745 and achieve ISO 13485certification. This development opened avenues for European maxillofacial and orthopedic surgeons.

Collaborating with the University of Liège, Cerhum aimed to provide a patient-specific synthetic alternative to autografts. MyBone, composed of hydroxyapatite, features a porous structure designed to facilitate bone growth, particularly for treating patients with severe facial deformities. The success of initial surgeries paved the way for its broader adoption in medical practice.

You might also like:

3D Systems launches new multi-material, jetted 3D printed denture solution in “industry first”: The new denture solution utilizes the firm’s NextDent Jet Denture Teeth and NextDent Jet Denture Base materials to provide customers with durable, long-wear, and aesthetically accurate denture prosthetics. The company claims that this material combination enables the production of wear- and stain-resistant teeth, and gums with exceptional break resistance.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Ada Shaikhnag

Leave A Comment