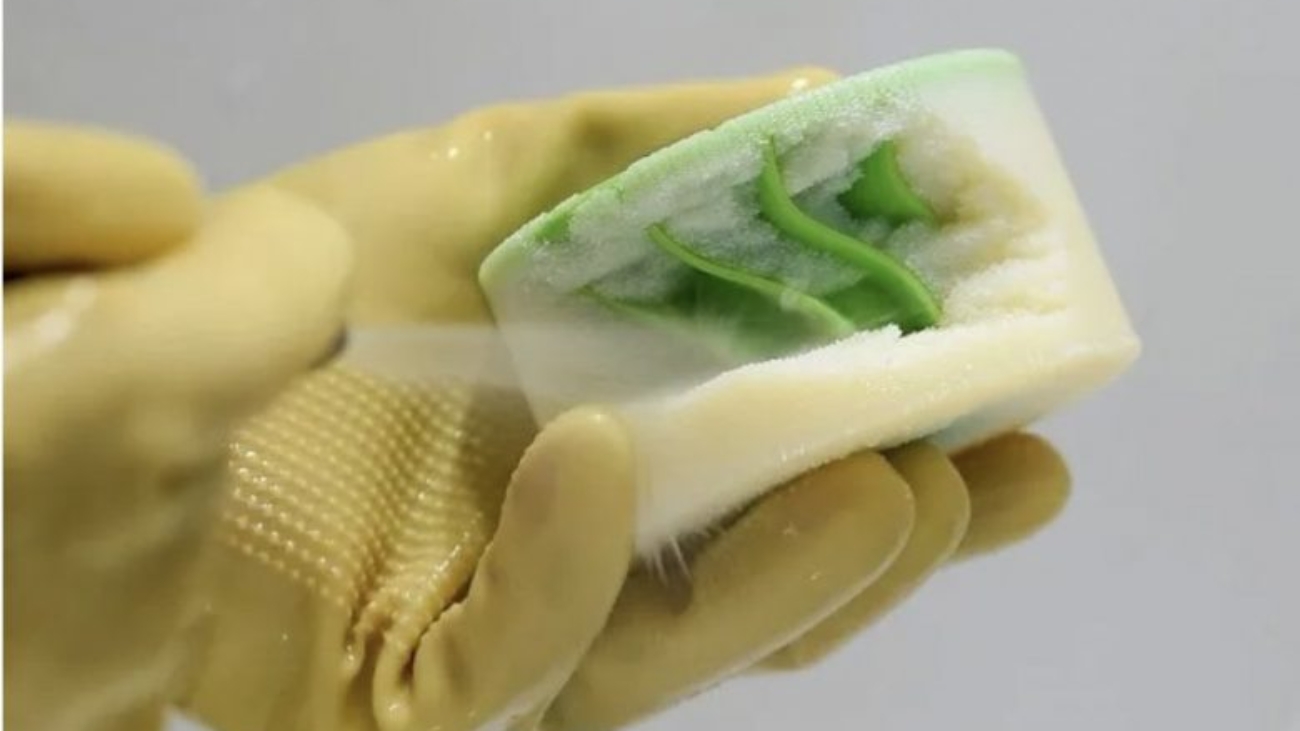

Oryx Additive‘s new Oryx Additive scaWaterjet is specifically designed for user productivity and comfort and engineered for function and quality. The new post processing system is part of the company’s goal to provide a more ergonomically considered solution to help industry manufacturing scale up their support removal efficiencies and improve other finishing processes.

Manufacturing on Demand

“Our vision at Oryx is to achieve the full potential of additive manufacturing by collaborating with customers and being a trusted and responsive partner. With the scaWaterjet, all users may expedite their finishing and support removal with the reliability expected at the industrial level. “We are excited to launch this new and innovative product” said Keith Jeffcoat, Chief Executive Officer, Oryx Additive.

Oryx Additive specializes in the design, development, and manufacturing of finishing and secondary processing equipment for additive manufacturing. Oryx builds with a heavy focus on the reliability and durability that the additive manufacturing industry demands. Their SCA product line includes the new scaWaterjet, the tried-and-true sca1200ht as well as the sca3600. The company distributes its products across multiple sub-categories of the additive manufacturing industry, including consumer products, design and engineering, automotive, aerospace, medical, and various additive manufacturing verticals.

The Oryx systems are currently available and may be purchased online at www.oryxadditive.com or through our reseller network. Feel free to contact us to explore how we may assist in providing additional information or product testing for your unique needs and applications.

You might also like:

Sindoh presents Sindoh S100, its first industrial polymer SLS 3D printer: The Sindoh S100 features a large build volume of 510 x 510 x 500 mm. It is intended as a manufacturing-proof machine that guarantees the reproducibility of the builds with consistent printing accuracy. It provides an industry-leading scanning speed of up to 15m/s (33ft/s) and is equipped with 2 lasers with each laser covering the full printing field. The lasers have a variable spot size thanks to 3D axes scanning technology which makes it possible to change the spot size on the fly, independently for each laser. Combined with the capability to work with variable layer thicknesses, this new machine guarantees very high productivity. Sindoh S100’s semi-automatic calibration function and remote diagnostic maintenance capabilities ensure high efficiency in operation and maintenance.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: VoxelMatters

Leave A Comment